HDPE Geocell with Various Parameters from China Supplier

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 9999999 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We provide Geocells with various parameters. If you have procurement needs, please contact us, and we will provide you with samples and the lowest price of the factory. Our products have passed the CE certification of EU. If you need the parameters of various types of Geocellss, you can contact us to obtain the product atlas.

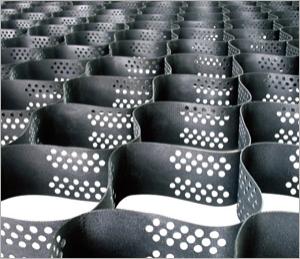

What is a Geocells?

Geocells is a three-dimensional network cell structure formed by high-strength welding of reinforced HDPE sheet materials. It is generally welded by ultrasonic needle. Some holes are drilled on the diaphragm due to engineering needs.

Characteristics of Geocells

1. It is flexible, transportable and collapsible. During construction, it can be tensioned into a mesh and filled with loose materials such as soil, gravel and concrete to form a structure with strong lateral restrictions and large stiffness.

2. Light material, abrasion resistance, stable chemical performance, light and oxygen aging resistance, acid and alkali resistance, suitable for different soil conditions such as desert.

3. High lateral limit and anti-skid, anti deformation, effectively enhance the bearing capacity of the subgrade and disperse load.

4. Changing geometric dimensions such as Geocells height and welding distance can meet different engineering needs.

5. Flexible, small transport volume; Convenient connection and fast construction speed.

Characteristics of Geocells:

1. It can be expanded and contracted freely, transported and stacked. During construction, it can be tensioned into a network and filled with loose materials such as soil, gravel and concrete to form a structure with strong lateral restrictions and large stiffness.

2. It is light, wear-resistant, stable in chemical performance, resistant to light and oxygen aging, acid and alkali, and suitable for different soil conditions such as desert.

3. High lateral limit and anti-skid, anti deformation, effectively enhance the bearing capacity of the subgrade and disperse load.

4. Changing geometric dimensions such as Geocells height and welding distance can meet different engineering needs.

5. Flexible, small transportation volume, convenient connection and fast construction speed. That is to say, once the load acts on the subgrade, a wedge-shaped active area will be formed under the load, which will be squeezed through the transition area, so that the passive area will bulge.

Components of Geocells

Geocells is a mesh cell structure formed by high-strength HDPE or PP copolymer broadband through strong welding or riveting. It is flexible and can be folded during transportation. When it is used, it is opened and filled with earth rock or concrete materials, forming a structure with strong lateral restrictions and large stiffness. It can be used as cushion to treat soft foundation to increase the bearing capacity of the foundation, and can also be laid on the slope to form a slope protection structure, and can also be used to build a retaining structure.

Use of Geocells

1. It is used to stabilize highway and railway subgrade.

2. It is used to control levees and shallow river channels bearing gravity.

3. Mixed retaining wall used to prevent landslide and loaded gravity.

4. When encountering soft foundation, the use of Geocells can greatly reduce the construction labor intensity, reduce the subgrade thickness, and the construction speed is fast, the performance is good, and the project cost is greatly reduced.

Engineering Application of Geocells

1. Treat half filled and half excavated subgrade. When building an embankment on a slope with a natural gradient of more than 1:5, steps shall be excavated at the base of the embankment, and the width of the steps shall not be less than 1M. When building or rebuilding the highway by stages, steps shall be excavated at the junction of the fill slopes of the new and old subgrades. The width of the steps of high-grade highways is generally 2M. Geocellss shall be laid on the horizontal surface of each step, and the reinforcement effect of the facade side of the Geocellss shall be used, Better solve the problem of uneven settlement.

2. Subgrade in windy sand area. The subgrade in windy sand area shall mainly be low embankment, and the filling height is generally not less than 0.3M Due to the professional requirements of low subgrade and heavy bearing for subgrade construction in wind blown sand area, the use of Geocells can play a side limiting role for loose filler, and ensure that the subgrade has high stiffness and strength within a limited height to withstand the load stress of large vehicles.

3. The abutment back subgrade is filled with reinforcement. The use of Geocells can better achieve the purpose of reinforcing the abutment back. Enough friction can be generated between the Geocells and the filler, which can effectively reduce the uneven settlement between the subgrade and the structure, and ultimately effectively alleviate the early impact damage of "abutment bump" disease on the bridge deck.

4. Subgrade in permafrost regions. When constructing fill subgrade in permafrost regions, the minimum fill height shall be reached to prevent the occurrence of frost boiling or the reduction of the upper limit of the frozen layer, which may cause excessive settlement of the embankment. The unique facade reinforcement effect of the Geocells and the effective implementation of the overall lateral limit can ensure the minimum fill height in some special sections to the greatest extent, and make the fill have high quality strength and stiffness.

5. Treatment of loess collapsible subgrade. When expressways and Class I highways pass through collapsible loess and loess sections with good compressibility, or when the allowable bearing capacity of the high embankment foundation is lower than the pressure of the vehicle load and the dead weight of the embankment, the subgrade should also be treated according to the requirements of the bearing capacity. At this time, the superiority of the geotextile cell will undoubtedly appear.

6. Saline soil and expansive soil. The expressway, Class I highway, shoulder and side slope constructed with saline soil and expansive soil are all reinforced. The facade reinforcement effect of the cell is the most excellent one among all reinforcement materials, and it has excellent corrosion resistance, which can fully meet the requirements of building highways in saline soil and expansive soil.

FAQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q:Can geocells be used in soil reinforcement for underground tunnels?

- Yes, geocells can be effectively used in soil reinforcement for underground tunnels. Geocells are three-dimensional cellular confinement systems made from high-density polyethylene (HDPE) that can be filled with soil, aggregate, or other suitable materials. They provide a stable and strong reinforcement layer, preventing soil erosion and improving load-bearing capacity. Geocells are widely used in various civil engineering applications, including the construction of underground tunnels, as they enhance the stability and overall performance of the soil structure.

- Q:Can geocells be used in channel lining?

- Yes, geocells can be used in channel lining. Geocells are cellular confinement systems made from high-density polyethylene that can provide erosion control and stabilization in channels. They can be filled with soil, concrete, or other materials to create a stable and durable lining for channels, preventing erosion and improving water flow.

- Q:How do geocells help with load-bearing capacity?

- Geocells help improve load-bearing capacity by confining and stabilizing the infill material within their honeycomb-like structure. This confinement prevents lateral spreading and enhances the material's ability to distribute and withstand heavy loads, thus increasing the overall load-bearing capacity of the structure.

- Q:Do geocells require any special permits for installation?

- Yes, geocells generally do not require any special permits for installation. They are considered a low-impact development technique and are often classified as a temporary or semi-permanent structure. However, it is always advisable to check with local authorities and building codes to ensure compliance with any specific regulations in your area.

- Q:How do geocells improve soil stabilization?

- Geocells improve soil stabilization by confining and reinforcing the soil, preventing lateral movement and improving load-bearing capacity. The interconnected cells create a network that distributes the load evenly, reducing soil erosion and promoting vegetation growth. Additionally, geocells enhance soil compaction and increase shear strength, making them highly effective in stabilizing slopes, retaining walls, and roadways.

- Q:Are geocells resistant to punctures?

- Yes, geocells are generally resistant to punctures due to their high-strength cellular structure and durable materials. They are designed to withstand various stresses and loads without getting punctured, making them suitable for a wide range of applications in civil engineering, landscaping, and erosion control.

- Q:How do geocells improve the stability of slopes?

- Geocells improve the stability of slopes by providing a strong and stable foundation. The interconnected cells form a three-dimensional grid that confines and reinforces the soil, preventing erosion and controlling slope movement. This increases the overall stability of the slope and reduces the risk of landslides or slope failures.

- Q:Can geocells be used in military applications?

- Yes, geocells can be used in military applications. Geocells are versatile geosynthetic products that provide soil stabilization, erosion control, and load support, making them suitable for various military engineering projects. They can be used to create temporary roads, landing strips, and helipads in remote or challenging terrains. Additionally, geocells can be deployed for constructing protective barriers, fortifications, and perimeter walls. The lightweight and easy-to-install nature of geocells make them valuable tools for military operations and infrastructure development.

- Q:Can geocells be used in pond and lake lining projects?

- Yes, geocells can be used in pond and lake lining projects. Geocells are a type of cellular confinement system that can provide stability and reinforcement to the soil or aggregate used in lining ponds and lakes. By using geocells, the lining material is confined within the cells, preventing erosion and maintaining the integrity of the lining system. Additionally, geocells can enhance the load-bearing capacity of the lining material, making it suitable for various applications, including pond and lake lining projects.

- Q:Can geocells be used for soil stabilization in residential areas?

- Yes, geocells can be used for soil stabilization in residential areas. Geocells are a cost-effective and efficient solution for reinforcing weak soils, preventing erosion, and stabilizing slopes, which are common challenges in residential areas. They provide structural support and enhance load-bearing capacity, making them suitable for various applications such as driveways, parking lots, and retaining walls. Additionally, geocells can promote vegetation growth and help with stormwater management, making them a viable option for soil stabilization in residential areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geocell with Various Parameters from China Supplier

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 9999999 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords