Geogrid Tx160

Geogrid Tx160 Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleGeogrid Tx160 Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Tx160 supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Tx160 firm in China.Hot Products

FAQ

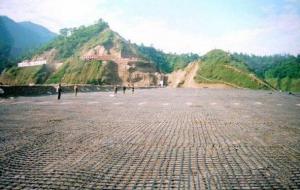

- Geogrids improve the load distribution in pavements by distributing the applied load over a larger area, reducing the stress on the pavement structure. They act as a reinforcement material, enhancing the pavement's stability, strength, and overall performance. By interlocking with the surrounding soil or aggregate, geogrids increase the confinement and lateral restraint, preventing the lateral movement of materials. This helps to minimize the development of cracks, rutting, and deformation, ultimately extending the lifespan of the pavement.

- Is there any difference between glass fiber grille and geogrid

- There are many kinds of Geogrid

- What are the specifications and models of Geotextiles and geogrids on the highway

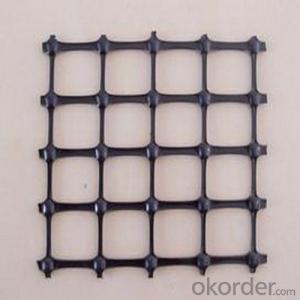

- One way plastic geogrid TGDG25 TGDG50 TGDG110 TGDG120 TGDG180 width of 1 m -3 m TGDG150 (TGDG35) TGDG80Bidirectional geogrid TGSG15-15 TGSG25-25 TGSG30-30 TGSG40-40 width 2-5M meters (TGSG20-20)

- There are several factors that can affect the installation of geogrids, including soil conditions, site preparation, weather conditions, and proper equipment and installation techniques. Soil conditions play a crucial role as the geogrid needs to be installed in a stable and compacted soil to ensure proper load distribution. Site preparation involves removing any vegetation, debris, or loose soil, and ensuring a level and even surface for the geogrid installation. Weather conditions such as heavy rainfall or extreme temperatures can affect the installation process, as well as the performance of the geogrids. Lastly, using the correct equipment and following proper installation techniques is essential to ensure the geogrids are properly anchored and aligned, ultimately ensuring their effectiveness and longevity.

- What criteria should be used in the construction of Geogrid

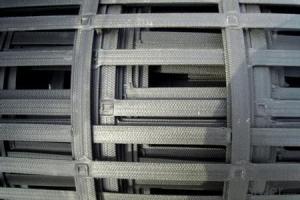

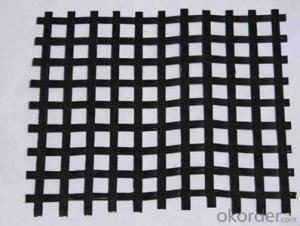

- A brief introduction of geogrid:A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid.

- Geogrids improve the performance of geogrid-reinforced earth walls by providing reinforcement and stability to the soil. They distribute the loads applied to the wall more evenly, reducing the risk of wall failure and enhancing its overall strength. Additionally, geogrids increase the friction between soil particles, preventing soil movement and improving the wall's resistance to lateral pressures.

- Geogrids help in reducing construction equipment requirements by providing soil stabilization, reinforcement, and confinement. They distribute the load across a wider area, reducing the need for heavy machinery and excavation. This results in cost savings, less fuel consumption, and faster construction processes.

- Geogrids and geonets are both geosynthetic materials used in civil engineering and geotechnical applications, but they have distinct differences. Geogrids are typically composed of high-strength polymers or fiberglass with a grid-like structure, offering tensile reinforcement to soil or other materials. They are primarily used for soil stabilization, slope reinforcement, and retaining wall construction. On the other hand, geonets are three-dimensional, open-mesh structures made of polymer materials. Geonets provide drainage and filtration capabilities, making them suitable for applications such as landfill leachate collection, erosion control, and gas venting. While geogrids focus on soil reinforcement, geonets specialize in drainage and filtration functions.