High Strength PP Woven Geotextile Geotextile Manufacturers/polypropylene woven geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Strength PP Woven Geotextile Description:

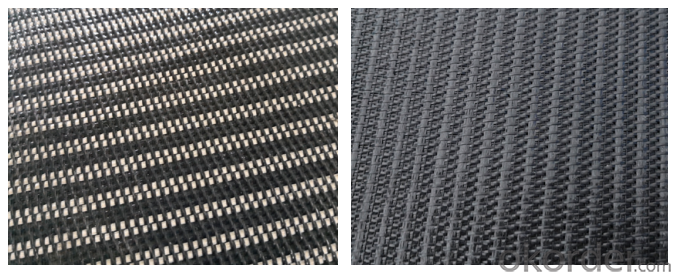

CNBM Geotextile is manufactured from woven high tenacity polypropylene multifilament yarns, which are woven into a stable network such that the yarns retain their relative position. CNBM Geotextile is inert to biological degradation and resistant to naturally encountered chemicals, alkalis, and acids etc. Used in coastal protection,reinforced & dewater etc.

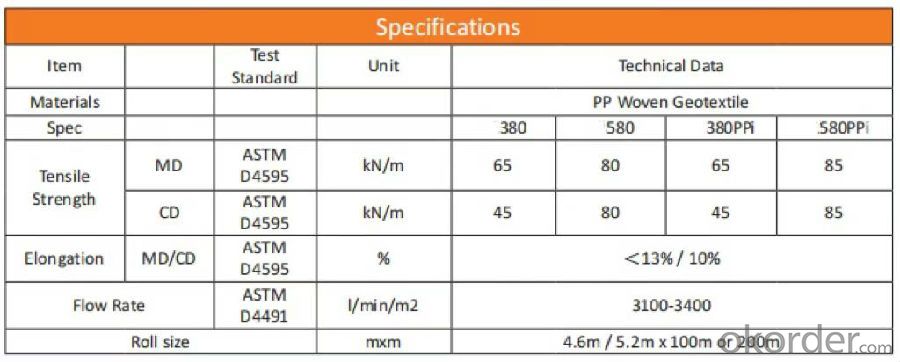

Product Popular Specification:

PP High Strength Woven Geotextile Features:

High tensile strength at low elongation

High modulus

Excellent resistance to mineral acids

Good durability to ensure structure safety

Excellent chemical resistance, even in alkaline soils

High quality and durability to ensure structure safety

High mechanical performance

High permittivity and water flow rates

Proven performance for most stabilization and receforcement applications

Extensive range of size, thickness and grades

Easy handling and installation

Ensured quality

Cost-effective

Fast delivery

PP Woven Geotextile Application:

PP woven geotextile is cost effective and availbale in various tensile strengths, woven open sizes to meet extensive project stabilization and reincrocement requirements.

Earthwork Construction

Steep side slope reinforcement

Embankment stablization and reonforcement

Bridging over sinkholes

Roadway and Railway Construction

Base Reinforcement

Subgrade stabilization

Water infrastructure

Marine and coastal construction

Seawalls and breakwaters

Riverbank and channel protection

Airport runway

Beach reclamation

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:Can geotextiles be used in retaining wall reinforcement?

- Yes, geotextiles can be used in retaining wall reinforcement. Geotextiles are commonly used in retaining walls to provide soil separation, filtration, and reinforcement. They can help prevent soil erosion and improve the stability and longevity of the retaining wall.

- Q:Why do you want to wrap the geotextile

- Filter function, filter function, I am specializing in the production of geotechnical materials

- Q:What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, there are several factors that need to be taken into consideration. These include the type and strength of the geotextile material, the angle of the slope, the height of the slope, the soil properties, the potential for water infiltration and drainage, the stability of the slope, and the overall aesthetic requirements. Additionally, factors such as the surrounding environment, climate, and any potential environmental impacts should also be considered during the design process.

- Q:Related applications, product applications, industrial structure and distribution

- Road cloth, that is, geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile with excellent filtration, drainage, isolation, reinforcement, protection, with a light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. The application of geosynthetics originated in the 1950s, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple acupuncture non-woven geotextile" (GB / T -1998) standard, the current geotextile has been widely used in many areas. Geotextile mainly in the following three series: 1, acupuncture non-woven geotextile, specifications 100g / m2-600g / m2 between any choice, the main raw material is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture, Uses are: river, sea, lake embankment slope protection, reclamation, wharf, ship lock flood control and other projects, is through the filter to play a soil and water conservation and effective way to prevent piping. 2, acupuncture non-woven and PE film composite geotextile, specifications have a cloth a film, two cloth a film, the largest width of 4.2 meters The main raw material is to use polyester staple fiber non-woven, PE film through the composite , The main purpose is anti-seepage, apply to railways, highways, tunnels, subways, airports and other projects. 3, non-woven and woven composite geotextile, a variety of non-woven and polypropylene filament woven composite, non-woven and plastic woven composite, suitable for foundation reinforcement, adjust the permeability coefficient of the basic engineering facilities.

- Q:What are the different geotextile installation techniques in filtration?

- Some of the different geotextile installation techniques in filtration include direct placement, wrap and trench, and sand bag placement. Direct placement involves placing the geotextile directly on the soil surface, while wrap and trench involves wrapping the geotextile around a soil layer or pipe and placing it in a trench. Sand bag placement involves constructing sand bags filled with soil and placing them against the geotextile to hold it in place. These techniques help to ensure proper filtration and prevent soil erosion.

- Q:Hope expert expert to give the answer

- The ditch is the ditch at the edge of the roadbed, mainly used to collect and exclude a small amount of surface water within the roadbed and flow to the roadbed; drainage ditch is the ditch, cut ditch, roadbed near the water discharged to the bridge or road Where the ditch in the natural river ditch. Geotextile is a kind of synthetic high strength fiber material which is used to improve the bearing capacity of subgrade when the bearing capacity of the foundation is poor. It has many kinds of fiber materials. The purpose is to improve the bearing capacity and prevent the cracks in the road surface.

- Q:How do geotextiles help with reinforcement of steep slopes?

- Geotextiles help with the reinforcement of steep slopes by providing stability and preventing erosion. They are often used as a reinforcement material to increase the shear strength of the slope and improve its overall stability. Geotextiles help distribute the load across the slope, reducing the risk of landslides or slope failure. Additionally, they allow for effective drainage, preventing the accumulation of water behind the slope, which can further weaken it.

- Q:What are the applications of geotextiles in geotechnical engineering?

- Geotextiles have numerous applications in geotechnical engineering, including soil stabilization, erosion control, drainage systems, and filtration. These versatile materials can be used to reinforce weak soils, prevent soil erosion on slopes, and improve the overall stability of various structures, such as roads, embankments, and retaining walls. Additionally, geotextiles can act as filters to separate different soil layers, allowing for proper water drainage and preventing clogging. Overall, geotextiles play a crucial role in enhancing the performance and longevity of geotechnical projects.

- Q:What are the design considerations for geotextile-reinforced soil walls?

- Some of the design considerations for geotextile-reinforced soil walls include the selection of appropriate geotextile material, determining the required strength and stability of the wall, evaluating the site conditions and soil properties, considering the drainage requirements, ensuring proper connection and anchorage of the geotextile to the wall, and considering any potential environmental factors that may affect the performance of the wall.

- Q:Are geotextiles suitable for use in bridge construction?

- Yes, geotextiles are suitable for use in bridge construction. Geotextiles offer various benefits such as soil stabilization, erosion control, and drainage improvement, which are crucial for the long-term durability and performance of bridges. Additionally, geotextiles can help distribute loads and reduce stresses on the bridge structure, enhancing its overall stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength PP Woven Geotextile Geotextile Manufacturers/polypropylene woven geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords