Wood Plastic Composite Decking with SGS and CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

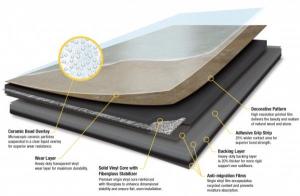

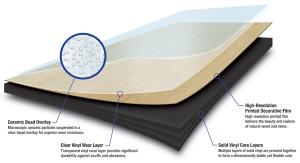

Structure of Wood Plastic Composite Decking

| 1.thickness: | 20mm,21mm,22mm,23mm,25mm, More items for your option |

| 2.width: | 140mm,150mmmm |

| 3.Length: | 2, 2.2,3,4...5.8 |

| 4.Color: | Black, Brown, Redbrown, teakwood, redwood, red, yellow. |

| 5.Surface: | Smooth, Brushed, Wood Grain & Sanded |

| 6.Component: | 30% HDPE+ 60% Bamboo Fibers +10% Chemical Additives |

| 7.Applications: | Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground. |

| 8.Packing | PE Film + WPC Pallet (length of 0-3m) |

| 9.Certificate | CE/ISO, ASTM, Fire Resistant, Anti UV, Anti Slip |

Main Features of Wood Plastic Composite Decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

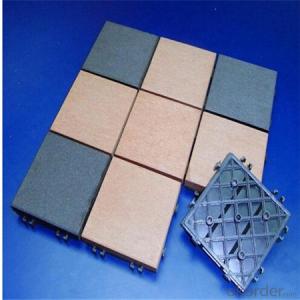

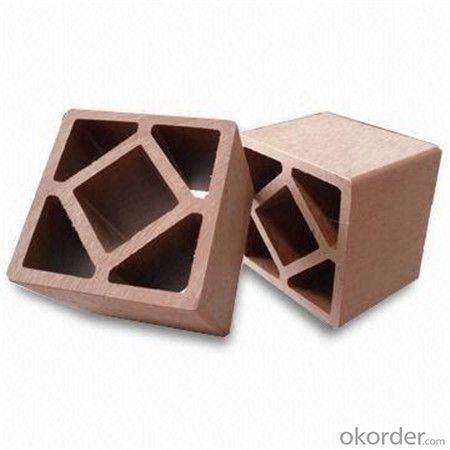

Picture show of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

Name | Wood Plastic Composite Decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Wood Plastic Composite Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q:Plastic foam on the floor there is no effect of moisture

- The plastic film under the wooden floor is called the ground mat, which can be used to play the role of moisture. Prevent moisture and moisture, so as to avoid the floor because of water seepage to the wood floor deformation. If there is no ground floor and the floor will be rubbing friction sound. There is also can play a role in the formation of the ground. Is an indispensable procedure.

- Q:The new rent a house, rough housing, house, do not want to decoration, but the cement really ugly, but the old feeling clean and fresh, a plastic carpet, feel the taste, said that before reading not made of plastic cloth, do not know whether to shop on the ground is also very harmful to me? Want to know now: plastic carpet and cement that is more harmful to human body?

- So take a look at the level of plastic carpet:The carpet is divided into six grades according to the different performance(1) light household level: placed in infrequently used rooms or parts;(2) medium grade or light grade: for master bedroom or dining room;(3) the general level of household or moderate professional use: used for living room, frequent traffic areas such as staircases, corridors, etc.;

- Q:What is the plastic floor and what is the compound floor?

- The floor has a new material composition, water resistance, generally suitable for public use. Composite floor, broadly speaking, refers to the structure of several layers of the composite floor, such as: laminate flooring, multi-layer solid wood flooring, bamboo flooring, etc..

- Q:How much is a plastic floor in a ping pong court?

- Table Tennis plastic floor brand domestic price per square meter from dozens of dollars to more than and 100 within this range, foreign imports are more than and 100 to two hundred or three hundred

- Q:Such as the title, do not know what is the real wood floor shop? The following is the keel I am looking for the materials and the advantages and disadvantages, we have what opinions and suggestions might as well talk about... 4, keel laid the keel: many materials, the most traditional is also plastic, wood keel, wooden keel and so on Aluminum Alloy 1): on the ground drill, fixed wooden keel, wooden keel on surface leveling the floor with a nail, will start...Home renovation renovation of the old house, the living room plus two bedroom only 41 square meters, which is more suitable for...In addition, the room is small, the shop is too thin and good-looking and consumption of materials, want to shop 455*90*1.8 or 455*120*1.8

- Home is home renovation, so could not live for a long time, suggested the use of wooden keel, more environmentally friendly, but in which you want to add pepper and aniseed and lime mothproof, decadent

- Q:Material advantages of plastic flooring

- According to its basic raw materials can be divided into polyvinyl chloride (PVC) plastic, polyethylene (.PE) plastic and polypropylene (PP) plastics, etc..

- Q:What are the hazards of plastic floor

- Floor leather containing lead compounds, in the use of the process, with the floor leather wear, lead content continues to spread, the formation of lead dust in the air, easy access to infants and young children.

- Q:Is the plastic paper between the wood floor and the closet

- Under the wooden floor there are moisture-proof pad, no need to pad plastic paper

- Q:What is the price per square metre of plastic floor?

- Plastic floor price gap is small, good quality plastic floor price: 45 yuan -80 yuan between. Plus plastic floor accessories and some labor costs in the price: 100 yuan -120 yuan between

- Q:Water general plastic floor glue harmful to the human body

- The production process of domestic PVC sheet flooring is not mature, the compound PVC sheet flooring is a multilayer structure, domestic PVC manufacturers mostly use sheet flooring glue adhesive, in addition PVC production technology is not mature, especially in the use of additives, so the domestic PVC sheet flooring contain serious odor, the smell of formaldehyde gas

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Composite Decking with SGS and CE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords