Waterproof Recycling Flexible Clamp System / Slab Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

Waterproof Recycling Flexible Clamp System / Slab Formwork System

Description:

1. Brief introduction

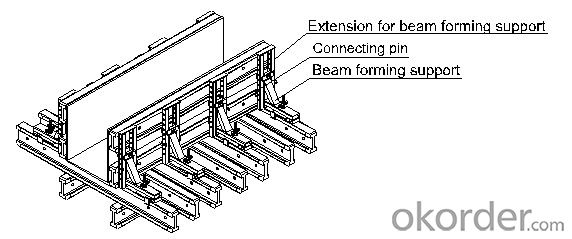

Beam clamp is the main components of the FL-CLAM system; it is designed as a special “waler” for beam’s side formwork, it is neat, flexible, easy operation. With FL-CLAM system, the formwork is quickly assembled and dismantled, time and labor are both saved.

2. Competitive advantage

① Construction efficiency is increased

FL-CLAM system is composed of timber-beam formwork, beam clamp, main beam and prop support system. It is easy and convenient to assembled, time and labor are both saved.

②Ingenious Structure design of beam clamp

As the picture shown, the beam clamp is composed of three parts, it is special tailor-made for timber-beam slab system. Its triangular structural shape guarantees system’s stability and force’s rationality.

3. Applications

- Q:How is the hydraulic support moving

- Hydraulic support is a kind of hydraulic power unit which uses the liquid pressure to generate the support force and realize the automatic movement to carry out the roof support and management. It is an indispensable supporting equipment for comprehensive mechanized coal mining. Used to control the coal mining face pressure structure of the mine. The surface pressure is applied to the hydraulic support.

- Q:Is the scaffolding scaffolding?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building.

- Q:Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q:Climbing and floor scaffolding advantages and disadvantages

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelf; the second is to remove the scaffolding disassembly process (after assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q:The difference between climbing and sliding mode

- Climbing is a short form of climbing template, also known as jumping abroad. It consists of climbing template, climbing frame (and some climbing no climbing) and climbing equipment composed of three parts, in the construction of shear wall system, the cylinder system and bridge pier and other high-rise structure is an effective tool. Because of the ability to self-climb, so no lifting machinery lifting, which reduces the construction of transport machinery lifting workload. Climbing scaffolds on self-climbing templates eliminates the need for external scaffolding during construction. In summary, climbing the template can reduce the number of lifting machinery, speed up the construction speed, so the economic benefits are better. Slip mode is a slow moving structure of the template, usually a fixed size of the stencil, drawn by the traction device.

- Q:What is a climbing frame?

- Taosheng Technology TOSUN as the leading research and development, production, sales, leasing and construction units in China, is committed to providing customers with comprehensive construction safety protection solutions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Recycling Flexible Clamp System / Slab Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords