Vertical Axial-flow Turbine Pump(API610 VS6)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

Vertical axial-flow Turbine Pump for low head

VTA Series is a sigle stage pump with axial-flow impeller

Hydraulic design of the pump bowl assembly

Wide range of hydraulic conditions to meet virtually every pumping service with optimum efficiency

Designed for high capacity, low head services

2. Application

Cooling water

Seawater and raw water intake

Industrial process pumps

Utility circulating water

Condenser circulating water pumps

Ash sluice

Fire-fighting

3. Technical Data

Capacities to 50000m3/h (220,000GPM)

Heads to 15m (50ft)

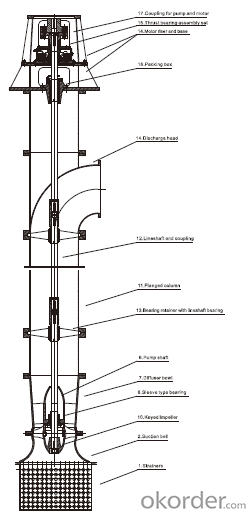

4. Pump Structure

5. FAQ

1 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

2 Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

3 How can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

- Q:I have coolant leaking out and i'm pretty sure now that it is the water pump. Question can water pumps leak even if the cars not running?Like a steady drip every two seconds? Forming a decent puddle after awhile, but when running the pump is'nt making any abnormal noises is that normal? Is there other clues to positively know the pump is bad? I cant believe how hard a job it looks like it would be to replace it there is no room! Anybody with some helpful how to's? how about an estimate on how much a shop would charge to do it?

- Yes, water pump seals will leak all the time (worse when under pressure). It is not a hard job if you now what your doing. Get a repair manual and make sure you have all the right tools and parts before you start.

- Q:A 0.13hp electric motor on a water well pumps water from 30.23m below the surface. The density of water is 1.0 kg/liter. How many kg of water does the motor pump in 2.20hr?

- It is known that 1 hp = 746 watts, so 0.13 hp = 97 watts = 97 Joules/s The amount of work to lift 1 kg water a vertical distance = 30.23 m = mgh mgh = (1)(9.81)(30.23) = 296.6 J no. of seconds in 2.20 hr = (2.2)(3600) = 7920 s total work output of a 0.13 hp pump in 2.2 hr if 100% efficient = (7920)(97) = 768,240 J no of kg lifted by 100% efficient pump/motor in 2.2 hr = 768,240/296.6 = 2590 kg ANS

- Q:i have a water leak near the water pump in my 1990 cadillac deville i replaced the water pump but it was remanufactured and a pipe on the back of the water pump can it be a heater core or should i buy a brand new one p.s. water leaks after it passes the radiator

- it would,nt be the heater core because it,s a good ways from the water pump. it might be that the water pump gasket slipped when you were putting it on or the by-pass hose is bad or loose. check all the hoses like both radiator hoses and where the heater hoses hook up to the block.

- Q:Two sewage pumps switch from each other, start with float switch control, the first sump, when the water is full, the first start, the second rotation to second units start, so the cycle of alternating

- Do you mean that 2 pumps are used in a hole? With float switch control, plus time relay 24 hours, every 12 hours at will, you set time, seconds, minutes can be

- Q:I had my timing belt replaced @ 80k (now have 138k) and was told by new mechanic that the water pump was not replaced then. Do I need to have pump replaced? What will happen if I don't? Thx

- Don't worry yourself over it. Just keep on driving it and sell it as you have planned.

- Q:Standard said that the fire pump should be certified by fire water pump, fire water pump and living water pump what is the difference?In addition to the brand, the same function of the pump, the impact of its price factors? Please advise Master ~ ~ ~ ~ ~ only feel so hard ah

- Fire pump and life pump essential difference, simply said: in the materialBecause we are used every day in the life of the pump, so there is no rust phenomenon, and the fire pump can not occur even in a hundred years to spend time, even some of the fire pump until life exceed the standard is not used, only periodically, so in order to prevent emergencies caused economic losses and personnel to design special pump different from the life of pump material as fire pump. Single stage centrifugal pump. The multistage centrifugal pump and pump life principle without any distinction, but the material will cast steel replacing 304, 309 stainless steel or copper materials, different specifications of other fire pump structure, materials should use copper and stainless steel.

- Q:I need a water pump for a 1930 Chrysler Roadster and have no idea where to get one. Any suggestions?

- try JC Whitney

- Q:here is the problem with my water pump control switch settings. the water is being used, runs dry and stays off for sometimes 3 minutes or so.i realize the springs control the cut in and cut out. do i need to make the spring more compressed to make the pump come on sooner? or do i need to make the spring looser to make the switch come on sooner?when i read/hear about adjusting the cut in. the answers seem vague because i do not know the perspecitve of the spring.does compressing the spring make the swith flip easier? or does compressing the spring make the switch harder to flip on?i installed a new 30/50 switch today. My air tank was at 50 or so PSI. but i dropped it to about 30. is the goeal to make the entire full system 50 pounds? because after my pump cycles i get about 70 psi!!!

- with the switch set to operate at 30/50 the tank should have 27 or 28 pounds of air with no water in tank and a faucet open with pump turned off...once this is set the pump will come on at 30 and off at 50 if it goes higher than this the switch is bad or the adjustments have been changed....tightening the tall spring turns both cut in and cut off pressure higher...loosening the tall spring turns both cut in and cut off lower....the short spring sets the difference between the two...tightening the shorth spring raises cut off pressure only...loosening the short spring lowers cut off pressure only....

- Q:What are some good brands of aquarium water pumps? I have had bad experiances with Hydor Seltz (cheapest ones I could find, ugg, I know, you get what you pay for) pumps, failing very quickly, and sounding like plastic gears grinding around inside. What is the best kind to get?I need one that's around 150gph

- PowerHead? or Sump Pump? I have used hagen aquaclear powerheads on my saltwater tanks for years 24/7 without a problem. I just purchased 3 MaxiJet 1200 powerheads and a wave timer to see haw they do, 6 months now 24/7 and so far so good. The longest lasting Sump Pump that I have ever owned is made by Ehime, I've had it for 14 years now and it's still going in one of my tanks. I better cross my fingers on that one.LOL

- Q:I want to buy a tree spraying rig for my property but would like to know its theoretical capabilities first. The rig has a gas powered diaphragm pump capable of delivering 20 GPM @ a maximum pressure of 300 psi. The hose coming from the pump is 150' long and is 0.75in diameter. It has a solid stream nozzle that measures 0.1875in diameter. What would the maximum theoretical elevation that this setup could deliver a steady stream of water? The nozzle would be aimed at between 45 and 60 degrees from horizontal.

- well water exerts about 1 atm pressure (15psi) for each 33 feet of depth so 300psi is about 10 atm meaning that your pump could support a column some 330ft high then figure what pressure you would need to make your spray effective and subtract 33ft per 15psi this is only a ballpark estimate losses in hoses will be significant

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vertical Axial-flow Turbine Pump(API610 VS6)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords