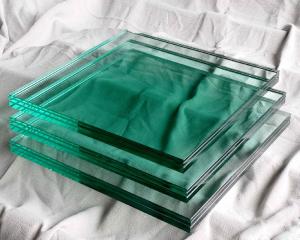

Tinted Float Glass European Gray Glass Float Glass Sheet 4-12mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinted Float Glass European Gray Glass Float Glass Sheet 4-12mm

Tinted float glass - Europe Grey

●Tinted float glass is formed when the molten glass mixed with an appropriate amount of pigment enters the tin bath via control gate and then enters the cooling bath after floats on the surface of molten tin under the action of centrifugal force and its surface tension, to get the two sides of glass to be smooth and even and ripple to disappear.

● Characteristic

Low transmission of ultraviolet ray, good shading effect;

Increase change in color of building appearance and a sense of creating higher value;

● Purpose

For buildings

For cars

For furniture and decoration

● Thickness Range

4mm-12mm

- Q:Why is the glass transparent? What is extended is water, ice and so on transparent things Please explain from the principle, simply, you do not ask Glass reflected light and other objects reflect the light is nothing different, Why some objects can be transparent, and some objects are not transparent

- The transparency should mean that its transmittance is relatively large, and the reflectivity is smaller

- Q:and does a building have to be on the bottom of a slope to flood?how can i stop it from flooding if so,

- It doesn't matter where the building is, it can be flooded if water rises above the bottom floor or basement. If the water hits the glass hard enough, or if it carries debris with any appreciable mass, it will smash the glass and enter the building quite easily. If the "flooding" is merely a result of runoff, you can prevent it by diverting the runoff (ex: from a slope) around the building. If the runoff is significant, more than one diverter swale can be created on the slope, or a larger one can be created. Typically they're either made out of concrete, or at least lined with rip-rap (chunks of rock to prevent erosion).

- Q:Is the car foil attached to the inside of the glass or inside? Will the wiper scratch the car's foil? Do not remove the window glass when attaching the car foil?

- Car foil is to be affixed to the inside of the car glass, the reason is very simple and then there will be no wind inside the rain, the use of the film will not be too much external interference, because the film stick to the wind, Baptism, sure that the paste is very strong, the use of the inside will not be affected.

- Q:I was doing architectural glass film, would like to take a government building project, but do not know where to start?

- Find out whether the film is a contractor or the development side of the project, that side is to find which side, are now low-cost contract.

- Q:What is the difference between domestic glass and car glass?

- Home glass and automotive glass from the production process that is certainly not the same, this is nonsense ~~~~ The corresponding national standards are not the same, relatively speaking, automotive glass standards than the standard requirements of a lot of home. But in China they belong to the scope of architectural glass ~ ~ ~ Specifically want to know which is not the same?

- Q:Thickness and specification of glass curtain wall in architectural drawings

- The third layer is 8mm thick glass

- Q:What is Article 20 of the Regulations on Safety Management of Building Glass?

- Four of the "building safety glass management regulations" (development and operation [2003] 2116) only 14, is not the twelfth ah? Article 12 Penalties ??(1) The safety glass production enterprise shall bear the corresponding legal responsibility for the serious economic loss or personal injury or death caused by the quality of the safety glass itself. The quality supervision department shall supervise and inspect the quality of its products and, if it fails to meet the quality requirements, It shall impose penalties on it, and the compulsory certification body shall revoke its certification certificate in accordance with the relevant provisions. According to the relevant provisions of the punishment, the certification body should bear the relevant legal responsibility. ??(2) The sales unit shall bear the corresponding legal responsibility for the unit that sells the unqualified safety glass in violation of these Provisions and the major economic loss or personal injury or death caused by the products it sells. ??(3) Any trade contract involving the import of unqualified safety glass in violation of these Provisions shall be subject to corresponding legal liability for causing significant losses or personal injury or death caused by the imported products. ??(4) The construction, design, construction and supervision units that violate these Provisions shall be punished by the construction administrative department in accordance with the relevant provisions. The unit that sells the unqualified safety glass in violation of the provisions shall be investigated and dealt with by the administrative department for industry and commerce according to law.

- Q:China's largest glass deep processing enterprises which

- China 's largest glass deep - processing enterprises Taiwan Glass Group, China' s largest glass of the original film, architectural glass company.

- Q:What is the characteristic of tempered glass?

- Glass is quartz sand, soda ash, feldspar and limestone as the main raw material, by melting, forming, cooling and curing non-crystalline inorganic materials. It has the general material is difficult to have the transparency, has excellent mechanical and mechanical properties and thermal properties.

- Q:photographing modern buildings

- for my area i exploit stainless-steel for my very own canines through fact ti is user-friendly to maintain clean, and would not weigh too plenty whilst i'm carrying 3 super bowls packed with nutrition. Plus once I drop them they don't destroy. the only reason i don't use plastic is using the fact my canines desire to bite something plastic :P i exploit plastic for my foster cats and foster doggies and characteristic in no way had any type of an infection. for my area i think of it somewhat is a few type of fable as I particularly have in no way widespread every physique's puppy to get an infection from a plastic bowl. as long as you hold them clean, plastic or stainless are the two super

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinted Float Glass European Gray Glass Float Glass Sheet 4-12mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords