Throttle Choke Valves with API 6A Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 800 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

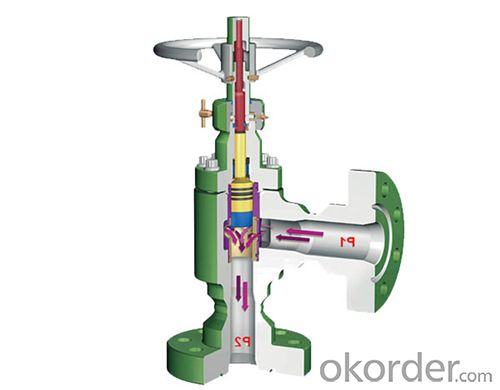

1. Structure of Throttle Choke Valves Description

1) Hole in Bonnet Nut to facilitate venting of pressure

2) Forged bonnet nut with lugs

3) H2 Classic prevents bonnet seal extrusion by means of body-to bonnet contact behind the O-ring seal

4) The bleed valve allows safe venting of the body cavity pressure

5) H2 is designed and manufactured in accordance with API 6A,including performance verification testing for PR2 level chokes

6) Forged body

2. Main Features of Throttle Choke Valves

1) API Standard

2) High quality and fast delivery

3) Easy operation and maintenance

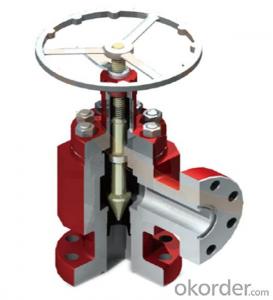

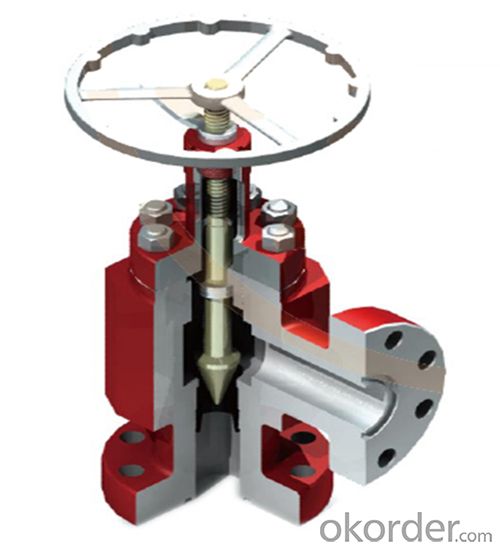

3. Throttle Choke Valves Images

4. Throttle Choke Valves Specification

Working Pressure :3,000Psi~20,000Psi

Nominal Bore :2-1/16"~4-1/16"

Working Temp :KU (-60℃~121℃)

Working medium:oil, gas, water, mud

PSL Class :PSL1~4

PR Class :PR1~2

Material Class :AA~HH

Actuator:Manual, hydraulic

End Connection:Conform to ANSI and API

5. FAQ of Throttle Choke Valves

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in Values products in China, can offer series of values to around the world.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:im trying to turn on my sprinklers from the valve manually,but doesn't seem to work, the valve it's an antisiphon rainbird valve with two little knobs, I know that one is the bleeder and the other the pressure control, or something like that, and the solenoid has the on and off arrows on it, but i can't do it anyways,they come on automatically right on time ,it's just the manual thing that i can't do, please help me,i really need it

- Here's okorder /... Simply twist the solenoid (the black cylinder with 2 wires coming from it) on the valve counter-clockwise 1/4 to 1/2 a turn. To shut off the valve, twist the solenoid clockwise until it is snug on the valve. Good luck!

- Q:I have a honda civic and i took it to get an oil change and they told me that i had an oil leak because my valve cover needed replacing. I did not let them do the work. I called my personal mechanic and he's out of commission for a little while, so he referred me to a friend of his. He said he cleaned all of the built up oil and replaced the valve cover. I noticed yesterday that my car looks like it is leaking oil really bad. I'm wondering, could this be from him washing the old oil that was leaking? My belts seem to be squeaking, like they do when it rains. Any ideas? could this just be excess water that he cleaned it out with?

- if the gasket was replaced then there may be other problems. take it to a dealer or reputable mechanic.. what kind of oil do you use, have seen this problem with plugged oil return holes. builds up pressure in valve cover and pushes it out the gasket. penz and quaker are noted for this problem.

- Q:fisher control valve

- One minor point to add to Artsupremo's answer. Valves can be either air to open or air to close. With one you start with the valve closed and the other with the valve open. The procedure is the same for both types of valves, I just wanted to clarify that point.

- Q:We have a 4 station sprinkler set-up. On the 4 station (last station to run) the Sprinkler headers are struggle to pop up water. From inside the house I hear the valve making a noise, that continues through out the entire run cycle. Any ideas on what causes these 2 problems to occur?

- Sounds like you have a valve that is not opening up fully. Is the noise coming from within the valve box or from the plumbing inside the house? I am assuming that it is coming from the valve box itself. If the valve is not opeing fully at that 4th station, the low volume of water flowing through the opening is causing a humming sound. And, with a low volume of water entering the lateral lines, your last station heads will not popup all the way, or may not popup at all. Check to make sure that you have no soft, wet, mushy areas on the turf in the last station area that would indicate a lateral line breakage or leek. If you do not see this occuring, you more than likely need to change out the valve and replace it with a new one for that particular system... Hope this answers your question. ...Billy Ray

- Q:I have a no start on a briggs and straon 16.5 OHV. It has spark, and fuel. and backfire's through the intake. I took off the top of the motor to check the key way and it was in place. I think its a valve timing issue but what times the valve? I have not removed the flywheel yet because i need a puller. Is there another key way under the flywheel that times the valves

- you can,t tell if the key way is sheared by looking at the flywheel it has to be pulled, did you hit something when mowing? good indication that the key is sheared, the valves run off a cam like in a car if not then you have a burnt valve

- Q:this valve uses in fire water lines...

- Deluge valves are used in special fire sprinkler systems. Open sprinklers or spray nozzles are attached to piping and to the valves. The valve is connected through control valves to a water supply system. The deluge valve consists of a housing, a swinging clapper like an ordinary check valve and a retractable keeper to hold the clapper tight to the valve seat. Electrical pneumatic or hydraulic mechanisms can retract the keeper, causing the valve to open. Other attachments provide for alarm sensors, gages and the like. See one at the link below

- Q:My mom just went to DR and will have open heart next Thursday for removal of anyerisum. She was told she has 2 heart valves instead of four. What does this mean? Is it normal?

- Your mom probably has a Bicuspid aortic valve, that she was born with.. it means that the valve between her heart and the aorta has two valve leaflets instead of the usual three valve leaflets (not four) in normal people. Bicuspid aortic valve is caused by fusion of two of the three leaflets. It's a fairly common congenital condition, and is associated with a risk of aortic aneurysm (a weakening of the wall of the blood vessel which then causes ballooning of the vessel wall)...usually of the ascending aorta. All the best for her safe recovery.

- Q:I have several stations in my automatic lawn sprinkler system. Each station has a valve that contains: 1. Manual Shutoff, 2. Flow Control Knob, 3. Solonid, 4. Anti-Siphon valve. Any way my question is this, Why does water continue to flow even when the manual shutoff is turned off and the flow control is also turned off?

- Any manual shutoff should shut the zone down completely, a flow control will limit the volume of water that leaves the valve by resticting the valve diaphram movement. If neither is working they may not be operational. A zone that continually runs either has a plunger stuck in the solenoid, a ruptured diaphram in the valve, or debris between the diaphram and valve body. If all these are contained in the valve, the most likely cause would be a bad diaphram or debris keeping the valve from closing completely

- Q:My third valve is always sticking, despite the fact that I oil them thoroughly every other day. It scrapes the sides of the case when I take it out/put it in, it's almost as if the valve is too big for it. Often times it will stick and I'll have to unscrew it and physically pull it out for it to be functional again.I've inspected it, and the inside looks just like the others which are fine. I've tried washing it, oiling it, and putting a trace amount of vaseline on it. What is the problem?

- Check the spring and plastic valve guide on top of the spring. I've seen these stick and the results are quite annoying, but once the spring moves up and down freely, so will the valve.

- Q:how long do people usually live after mitral valve repair?

- From what i've got study having it repaired rather than replaced has a much greater helpful restoration consequence. The survival fee is in the mid ninety's % clever so curiously like an rather secure surgical operation. Hoping she has a rapid restoration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Throttle Choke Valves with API 6A Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 800 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords