Tan BOPP Packing Tape Water Based Acrylic OPP Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

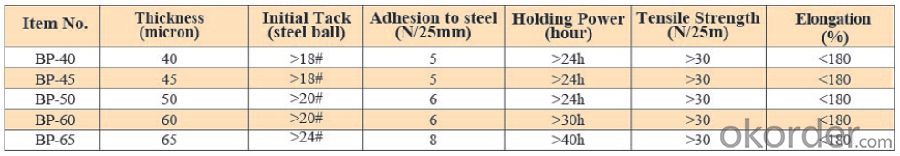

Material | BOPP film+pressure-sensitive glue |

Total Thickness | 35mic-65mic |

Width | 10/11/12/15/17/18/24/30/40/42/45/46.5/48/50/50.4/52.5/55/57/60/72mm |

Length | 30y-1000m |

Tensile | above360N/25mm |

Adhesion | above25N/25mm |

Initial Adhesive | 20-24# |

Color | Clear, white, yellow, red, blue, green, etc |

Tape Paper Core | 2.5/ 2.8/ 3/ 3.5/ 4/ 4.5/ 5/ 5.5/ 6 mm |

Jumbo Roll | 1280/980/960mmX4000m |

Available in maximum four colors print by Rotogravure Prints.(empty printing, full printing) | |

Payment | T/T(30% deposit, and the balance upon the copy of B/L ) |

L/C(30% deposit, the balance by L/C at sight ) | |

Main Market | North America/Asia/Western Europe/South America/Africa |

Certifications | CTI(TPCH,RoHs) |

MOQ | 5000rolls |

Product Discription

Applications:

Shipping, packaging, bundling, wrapping.

Ideal for sealing of cartons, merchandise, pallets

Excellent performer for both hand and machine application.

Advantages:

Characteristic:Strong adhesion,good for packing ,easy tear, low odor

Material:BOPP with high tension strength, good quality glue .

OEM Offer:The tape can be made as your request(weigh,length,microns,color,paper core etc)

Management:Has many firstlevel manager,and control the quality in the process of the production.

Glue store :Can store over 220T glue for one-time

FAQ:

1. Q:Can we order the customized logo tape?

A: Yes, we can offer the customized logo tape.

2. Q: Are you sure about the quality and length?

A: We are factory, Quality is the best advertisement. we can sure you about the quality and length.

3. Q:Can you make our logo on the paper core of the tape?

A:yes,we can help to print. and the mould cost will be $50. If the quantity is 300 cartons, then will be free of logo charge.

- Q:Xiangxi investment sealing tape how much profit

- The price of the transparent adhesive tape is very unstable, and the profit is hard to say. Today, the price of the goods is 13000 yuan per ton, and the volume will be 9000 yuan per ton tomorrow or soon

- Q:Is packaging tape easy to cut with scissors?

- Yes, packaging tape is typically easy to cut with scissors.

- Q:Is packaging tape safe to use on photographs?

- No, packaging tape is not safe to use on photographs as it can leave adhesive residue, damage the surface, or cause discoloration over time. It is recommended to use archival-quality photo-safe tapes or alternative methods for preserving and protecting photographs.

- Q:How do I prevent packaging tape from becoming too sticky?

- To prevent packaging tape from becoming too sticky, there are a few measures you can take: 1. Store tape in a cool and dry place: Heat and humidity can often cause the adhesive on packaging tape to become stickier. Ensure that you store the tape in a cool and dry environment to maintain its proper consistency. 2. Avoid contact with dust and debris: Dust and debris can stick to the adhesive side of the tape, increasing its stickiness. Keep the tape away from dusty surfaces and make sure the areas where you will apply the tape are clean and free from any loose particles. 3. Use a tape dispenser: A tape dispenser can help regulate the amount of tape you apply and prevent excessive stickiness. It allows for a more controlled application and ensures you don't use more tape than necessary. 4. Don't stretch the tape excessively: Stretching the tape too much while applying it can cause it to become stickier. Apply the tape smoothly without pulling or stretching it excessively, as this can activate the adhesive further. 5. Consider using low-tack or removable tape: If you consistently face issues with sticky packaging tape, you can opt for low-tack or removable tape. These types of tape have less aggressive adhesive properties and are easier to remove without leaving sticky residue. By following these tips, you can maintain the desired level of stickiness on your packaging tape and make your packaging process more efficient.

- Q:Can packaging tape be used for sealing packages with sharp or pointed objects?

- Yes, packaging tape can be used for sealing packages with sharp or pointed objects. However, it is recommended to take additional precautions such as cushioning the sharp or pointed objects with protective material or placing them in a sturdy box to prevent the tape from getting damaged or punctured during transit.

- Q:What is the best way to apply packaging tape?

- The best way to apply packaging tape is to first ensure that the surface is clean and dry. Start by holding the tape dispenser at a slight angle and pressing firmly on the surface, moving the dispenser smoothly in a straight line. Avoid stretching or folding the tape as it can weaken its adhesive properties. Finally, use a sharp object to cut the tape cleanly, ensuring a secure and professional seal.

- Q:Can packaging tape be used for sealing glass or delicate items?

- Yes, packaging tape can be used for sealing glass or delicate items. However, it is important to handle the items with care and apply the tape gently to avoid any damage. It is recommended to use a cushioning material like bubble wrap or foam to provide additional protection before sealing with packaging tape.

- Q:Does packaging tape come in different materials for specific applications?

- Yes, packaging tape does come in different materials for specific applications. One common type of packaging tape is made of polypropylene, which is a versatile material suitable for general-purpose packaging. It is strong, durable, and resistant to moisture and temperature changes, making it suitable for a wide range of applications. However, for more specialized uses, different materials may be needed. For example, if you are packaging items that require extra security or tamper-evident features, you may opt for security tape. This type of tape is often made of a thicker and stronger material, such as polyester or reinforced paper, and is designed to leave a visible mark or message when tampered with. In certain cases, you may need to use packaging tape that is specifically designed for use in extreme temperature conditions. For instance, if you are shipping goods that will be exposed to freezing temperatures, you may need to use freezer-grade packaging tape that remains adhesive and effective in low temperatures. Similarly, some applications may require tape that can adhere to difficult surfaces like corrugated cardboard or recycled materials. In such cases, you may choose a packaging tape with aggressive adhesive properties or one that is specifically formulated for adhesion on challenging surfaces. Additionally, there are also eco-friendly options available for those who prioritize sustainability. Environmentally friendly packaging tapes are often made from renewable or recycled materials and use non-toxic adhesives. Overall, the choice of packaging tape material depends on the specific needs of the application, such as security, temperature resistance, surface compatibility, or environmental considerations. It is always important to select the appropriate tape to ensure the safe and secure packaging of your items.

- Q:How does packaging tape perform in high-temperature conditions?

- Packaging tape typically functions well in high-temperature settings, but its effectiveness can differ depending on the specific type and quality of the tape. Most packaging tapes are engineered to endure a range of temperatures and are generally resistant to heat up to a certain degree. However, it is important to note that extreme temperatures, particularly those surpassing the tape's specified heat resistance limit, can impact its adhesive properties and overall performance. When exposed to high temperatures, the adhesive on packaging tape may soften or weaken, leading to reduced bonding strength and potential tape failure. This can result in packages opening or becoming less secure during transportation or storage. Additionally, heat can cause the tape to lose flexibility, making it more susceptible to cracking or breaking. Thus, it is vital to choose packaging tape specifically designed for high-temperature environments if there is anticipated exposure to extreme heat. Certain types of packaging tape, such as fiberglass-reinforced or high-temperature resistant tapes, are better suited for enduring high temperatures. These tapes are often manufactured with special adhesives and materials that provide enhanced heat resistance and improved performance in extreme conditions. They are designed to maintain their adhesive strength, bonding capability, and structural integrity even when confronted with elevated temperatures. In conclusion, although packaging tape can generally endure high-temperature conditions, its performance may be compromised when subjected to extreme heat. Utilizing tapes specifically designed for high-temperature environments can help ensure optimal performance and securely seal packages even in challenging conditions.

- Q:How does packaging tape perform on porous surfaces?

- Packaging tape generally does not perform well on porous surfaces. Porous surfaces such as cardboard, paper, or fabric tend to absorb the adhesive on the tape, resulting in a weak bond and reduced effectiveness. It is recommended to use alternative methods or specialized tapes specifically designed for porous surfaces to achieve better adhesion and secure packaging.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tan BOPP Packing Tape Water Based Acrylic OPP Adhesive Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords