Steel Structure Warehouse/Workshop GB Standard Material

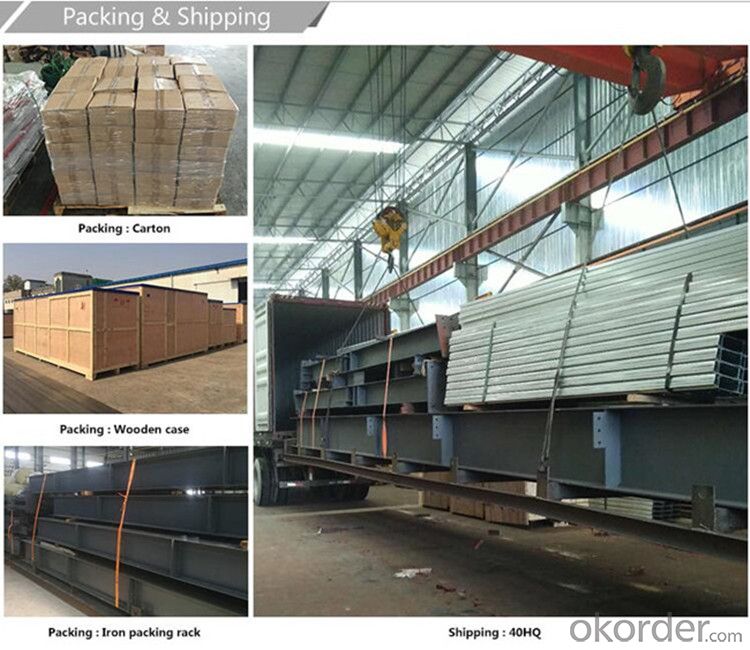

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel Structure Warehouse/Workshop

1. These products are customized products;

2. The following information is required to provide detailed quotation:

A. Project location:

B. Size: Length*width*height _____mm*_____mm*_____mm

C. Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

D. Snow load (max. Snow thickness)_____kn/m2, _____mm

E. Anti-earthquake grade_____

F. Brick wall needed or not. If yes, 1.2m high or 1.5m high?

G. Thermal insulation requirement. If yes, EPS/fiberglass wool/rock wool/PU sandwich panels will be suggested; If not, the metal steel sheets will be OK. The cost of the latter will be much lower than the former.

H. Door quantity & size _____units, _____(width)mm*_____(height)mm

I. Window quantity & size _____units, _____(width)mm*_____(height)mm

J. Crane needed or not

Characteristics

1. Enviromental friendly

2. Lower cost and maintenance

3. Long using time up to 50 years

4. Stable and earthquake resistance up to 9 grade

5. Fast construction, time saving and labor saving

6. Good appearance

Use

The steel workshop warehouse building is widely used for workshop plant, warehouse, office building,steel shed, aircraft hangar etc.

Technical Parameters

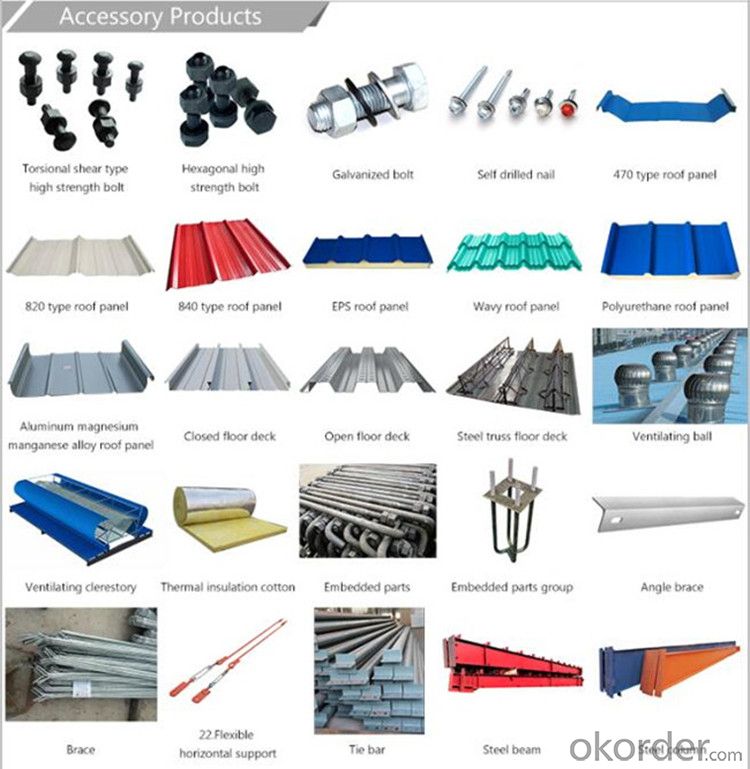

Items | Specification | |

Main Steel Frame | Column | Q235B, Q345B Welded H Section Steel |

Beam | Q235B, Q345B Welded H Section Steel | |

Secondary Frame | Purlin | Q235B C and Z purlin |

Knee brace | Q235B Angle Steel | |

Tie Rod | Q235B Circular Steel Pipe | |

Brace | Q235B Round Bar | |

Vertical and Horizontal Support | Q235B Angle Steel, Round Bar or Steel Pipe | |

Maintenance system | Roof Panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel /Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet |

Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

Accessories | Window | Aluminium Alloy Window / PVC Window / Sandwich Panel Window |

Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

Rainspout | PVC | |

Live load on Roof | In 120kg/Sq.m (Color steel panel surrounded) | |

Wind Resistance Grade | 12 Grades | |

Earthquake-resistance | 8 Grades | |

Structure Usage | Up to 50 years | |

Finishing Options | Vast array of colors and textures available | |

Paint Options | Zinc rich epoxy painting, one primary painting, two finish painting (gray paint, red paint, white paint, epoxy zinc etc.) Or Galvanized. | |

- Q:What are the common design considerations for steel residential or housing projects?

- Some common design considerations for steel residential or housing projects include structural stability, fire resistance, energy efficiency, and aesthetic appeal. It is important to ensure that the steel structure is capable of withstanding the intended loads and forces, and that it meets the necessary safety standards. Fire resistance is also crucial, with the use of fire-resistant coatings or materials to protect the steel from high temperatures. Energy efficiency can be achieved through proper insulation and the use of energy-efficient materials and systems. Lastly, the aesthetic appeal of the steel residential or housing project should be considered, with options for architectural finishes and designs that enhance the overall aesthetics of the structure.

- Q:How are steel structures designed for fireproofing?

- Steel structures are designed for fireproofing in order to prevent the spread of fire and to ensure the structural integrity of the building during a fire incident. There are several methods and techniques used to achieve fireproofing in steel structures. One common method is the application of fire-resistant coatings or intumescent paints. These coatings are specially formulated to expand and form an insulating char when exposed to high temperatures. This char acts as a barrier, protecting the underlying steel from the heat of the fire. These coatings can be applied to both the exposed structural steel elements as well as to the concealed ones. Another method used for fireproofing steel structures is the installation of fire-resistant insulation materials. These materials, such as mineral wool, ceramic fiber, or calcium silicate, are applied around the steel members to provide thermal insulation. They help in delaying the transfer of heat to the steel, thereby protecting it from reaching critical temperatures. In addition to coatings and insulation, fireproofing can also be achieved through the use of fire-resistant boards or panels. These boards are made from non-combustible materials, such as gypsum or cementitious boards, and are installed around the steel members to enhance their fire resistance. Furthermore, the design of steel structures for fireproofing also involves incorporating fire protection measures such as fire-rated walls, fire doors, and fire dampers. These components help in compartmentalizing the building and preventing the spread of fire to other areas, allowing occupants to safely evacuate and minimizing damage to the structure. It is important to note that the specific fireproofing design and techniques used for steel structures may vary depending on factors such as the building's occupancy type, size, and fire safety regulations. Therefore, it is crucial to consult with fire protection engineers and adhere to local building codes and standards while designing and implementing fireproofing measures for steel structures.

- Q:How are steel structures used in parking and vehicle management systems?

- Due to their durability, strength, and versatility, steel structures find wide application in parking and vehicle management systems. These structures not only offer the required stability and support but also ensure the safe and organized accommodation of large numbers of vehicles. In parking systems, multi-level parking garages are commonly constructed using steel structures. By vertically stacking vehicles, these garages maximize the utilization of available space. The steel framework allows for the creation of multiple levels, resulting in ample parking spaces for a significant number of vehicles. Moreover, these structures are designed to withstand heavy loads and adverse weather conditions, thereby guaranteeing the safety of both vehicles and users. Steel structures also play a vital role in the design of parking canopies or shade structures. These constructions provide protection against rain, snow, and excessive sunlight. Typically found in open parking lots or outdoor spaces, they offer shelter to vehicles while ensuring their long lifespan. In addition to parking systems, steel structures are crucial in vehicle management systems. For instance, steel bollards are employed to regulate and direct traffic flow in parking areas. These robust posts are often installed at entrances, exits, and pedestrian walkways, guiding vehicles and preventing unauthorized access. Furthermore, steel barriers and guardrails are frequently utilized to enhance safety in parking lots and garages. Serving as protective barriers, they prevent vehicles from colliding with pedestrians, structures, or other vehicles. Due to its high strength and impact resistance, steel is the preferred material for constructing these barriers. In conclusion, steel structures are indispensable components of parking and vehicle management systems. They provide the necessary support, protection, and organization required for efficient and safe parking operations.

- Q:How are steel structures designed for resisting live loads?

- Steel structures are designed to resist live loads by considering the expected forces and movements due to the occupants, equipment, and dynamic loads that are likely to be present during the structure's intended use. This involves careful analysis and calculation of the maximum expected loads and their distribution throughout the structure, ensuring that the steel members and connections are designed to safely carry and transfer these loads without excessive deflection or failure. Additionally, factors such as impact, vibration, and wind-induced movements are considered to ensure the structure's stability and safety under various live load scenarios.

- Q:How do steel structures perform in high winds?

- Steel structures perform exceptionally well in high winds. The inherent strength and durability of steel make it highly resistant to wind forces. Unlike other building materials, steel can flex and absorb the energy generated by strong winds, preventing structural failure. Additionally, the rigidity of steel allows for efficient load distribution, minimizing the risk of damage or collapse. Therefore, steel structures are a reliable choice to withstand the challenges posed by high wind conditions.

- Q:What is the role of steel in oil and gas facilities?

- The role of steel in oil and gas facilities is crucial as it is used extensively for constructing various components such as pipelines, storage tanks, and structural supports. Steel is preferred due to its high strength, durability, and resistance to corrosion, making it suitable for withstanding the harsh conditions and pressures associated with oil and gas operations.

- Q:How are steel structures used in military and defense facilities?

- Steel structures are extensively used in military and defense facilities due to their unique properties that make them ideal for the demanding requirements of such establishments. One key application is the construction of military hangars and aircraft maintenance facilities. These structures provide a secure and controlled environment for the storage and maintenance of military aircraft, offering protection against harsh weather conditions and potential threats. Moreover, steel structures are used in the construction of command centers, barracks, and other administrative buildings. These buildings require a robust and durable framework to withstand potential attacks and provide a safe working environment for military personnel. Steel is also utilized in the construction of ammunition storage facilities and armories. Its strength and fire resistance properties ensure the safety and security of stored munitions, minimizing the risk of accidents or unauthorized access. In addition, steel structures play a crucial role in the construction of military training facilities. These facilities often require large open spaces, which can be efficiently achieved using steel structures. Steel allows for large spans and column-free spaces, providing flexibility for various training activities such as obstacle courses, shooting ranges, and combat simulations. Another significant application of steel structures in military and defense facilities is in the construction of border checkpoints and security infrastructure. Steel barriers, fences, and gates are used to fortify perimeters and control access points, enhancing security and preventing unauthorized entry. Overall, the use of steel structures in military and defense facilities ensures the strength, durability, and security necessary to protect personnel, equipment, and strategic assets. The versatility and structural integrity of steel make it an essential material in the construction of these vital facilities.

- Q:What are the limitations of using steel structures in construction?

- There are a few limitations to using steel structures in construction. First, steel is susceptible to rust and corrosion, especially in humid or coastal environments. This requires regular maintenance and protective coatings to prevent deterioration. Second, steel has a high thermal conductivity, making it prone to expansion and contraction with temperature changes. This can lead to issues such as cracking or warping if not properly addressed. Lastly, steel structures can be more expensive compared to other materials, especially for small-scale or residential projects. However, despite these limitations, steel remains a popular choice due to its strength, versatility, and ability to support large-scale structures.

- Q:What are the different types of steel finishes used in structures?

- There are several types of steel finishes commonly used in structures, including galvanized, painted, and powder-coated finishes. Galvanized steel is coated with a layer of zinc to protect against corrosion. Painted steel finishes involve the application of a paint or coating to enhance aesthetics and provide additional protection. Powder-coated finishes involve a dry powder being applied electrostatically and then cured under heat, resulting in a durable and attractive finish that is resistant to chipping and fading.

- Q:How are steel structures used in the construction of railway bridges?

- Steel structures are commonly used in the construction of railway bridges due to their high strength-to-weight ratio and durability. The use of steel allows for the construction of long-span bridges that can support heavy loads, such as trains. It also provides flexibility in design, allowing for various architectural forms and configurations. Additionally, steel structures are resistant to corrosion, reducing the need for maintenance and ensuring the longevity of the railway bridges.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Structure Warehouse/Workshop GB Standard Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products