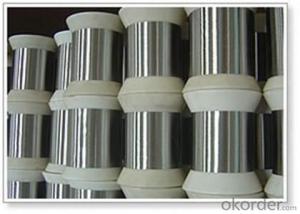

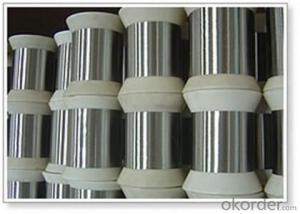

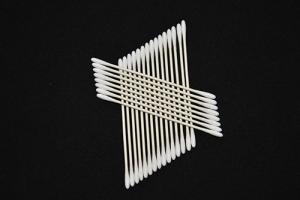

ss wire 410 for making scrubber,scoures

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel wire 201,304,316

1.Quality:ISO9001:200

2.Diameter:0.1-15mm

3.Type: hot rolled and pickled

4.Factory price

stainless steel wire 201,304,316

Steel mark includes: SUS201, SUS202,

SUS301, SUS302, SUS303, SUS304,

SUS304L, SUS316, SUS316L, SUS321,

SUS410, SUS430

| specifications and models table of steel wire | ||

| diameter mm | diameter mm | diameter mm |

| Φ0.5 | Φ1.8 | Φ5 |

| Φ0.6 | Φ2.0 | Φ5.5 |

| Φ0.8 | Φ2.2 | Φ6 |

| Φ0.9 | Φ2.5 | Φ6.3 |

| Φ1 | Φ2.8 | Φ7 |

| Φ1.1 | Φ3.0 | Φ7.5 |

| Φ1.2 | Φ3.2 | Φ8 |

| Φ1.4 | Φ3.5 | Φ8.5 |

| Φ1.5 | Φ4.0 | Φ9 |

| Φ1.6 | Φ4.5 | Φ9.5 |

Description:

1) Grade: 201,202,301,304,304L,310S,316,316L,410,420,430,etc.

2) Standard: AISI, ASTM, DIN, GB, JIS, SUS

3) Dimension:0.05mm-25mm

4) Finish: Black/Bright/Pickled/Polished

5) Length: Unlimited or as customer decided

6) Condition: Hot Rolled & Pickled, Hot Rolled Black Bar,Cold Drawn

7) Packing: Nylon bag or according to client's requirement

Terms:

Loading Port | Shanghai or Hongkong |

Delivery term | FOB,CFR, CIF etc. |

Lead time | 15-35 working days after received deposit |

Payment term | 30% by T/T as deposit., balance will be paid by T/T against copy of BL |

Quality assurance | Mill Test Certificate is supplied with shipment, third Party Inspection is acceptable |

Product Application | With bright surface, slight magnetism and no cracks on forming, is widely used in bicycle fittings, kitchen and sanitation tools, goods shelf, pet cages, gill racks, |

- Q:The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Look at that oil and then choose the emulsifier To use the all-around emulsifier for oil and other oil Used for lubricating oil, mechanical oil and mine Oil, clutch oil, gear oil, brake oil, engine oil, ink, demoulding oil, compressor oil, refrigeration oil, vacuum pump oil, the internal combustion engine oil (1: diesel engine oil. 2: gasoline engine oil. 3: ship oil), oil bearing, guide Rail oil, hydraulic oil, hydraulic oil, metal processing oil dynamic tools, electrical insulating oil, oil, heat conduction oil, rust-proof oil, special occasions, oil, turbine oil, quenching oil, fuel oil, oil have oil selection and other occasions Engine oil emulsifier, no oil emulsifier is the domestic initiative of non-toxic + environmental protection + high efficiency emulsifier. For the removal of oil emulsifier and oil emulsifier, nano-oil emulsifier is used for the removal of oil and oil emulsifier in addition to oil and inorganic oil

- Q:The heavy oil on the machine should use what cleaning agent to clean up?

- The downstairs brother was right. I'm the one who often USES this oil cleaner, Because it's local, it's clear that it works well. I recommend you to consult..

- Q:What are the methods of general cleaning of mechanical equipment?

- It is commonly used for dry cleaning and washing 1, dry cleaning: it is with a bit like a sponge absorbing water materials, such as spray (drop) some detergent or anything on the brush, complete with relatively wet objects in to wipe again, finally just now with the dry items all dry clean place (general comparison precision of the equipment) 2, rinse directly with water, direct and clear, and then dry (directly dry, the equipment is large). This kind of equipment is not afraid of water Most of it comes in the first way

- Q:What is suitable for factory cleaning equipment

- Industrial vacuum cleaner is used to collect waste gas, dust and debris from equipment in industrial production, purify workshop environment, and no secondary pollution. High pressure cleaning machine, clean equipment oil pollution, rust stain, and some areas with small and unsanitary areas.

- Q:Where can I buy cleaning equipment

- what about cleaning, washing? Cleaning? Wash the wall? Marble? Or what, is there a direction

- Q:What is the pool cleaning equipment

- Disinfection system (water treatment of swimming pool is very important, the water quality is not up to the standard to affect the opening) : Metering pump Drug delivery; Ozone generator. Lighting system (underwater lamp beautification swimming pool) : Pool wall lamp; Waterproof cable. Fully automatic thermostat (the temperature of the water in the swimming pool) : Fully automatic heating furnace; Water and water heat exchanger (commonly known as plate change); Temperature controller; Electric valve. Cleaning equipment (pool brush, leaf net, telescopic rod, suction head, wire brush). 5, the pool bank facility (escalator, departure stage). Water quality monitoring equipment (water quality monitor, test water box, water temperature meter). Water treatment pipe fittings.

- Q:How many kinds of cleaning equipment are there for cleaning companies?

- Ogilvy Lin cleaning cleaning tool use commonly: 2000 w vacuum suction machine, multi-function cleaning machine, polishing machine, glass scraper, with water, glass cutter, clean ball, microfiber cloth, towel (one-time), glass cleaner, clean neutral detergent, highly-effective cleaning agent, speed powder, seat belts, telescopic rod, brush, herringbone ladder, toolbox, rubber gloves and other professional tool

- Q:The main parameters of ultrasonic cleaning equipment

- The main parameters of ultrasonic cleaning equipment are internal slot size, frequency, power and heating power.

- Q:How often do the reverse osmosis of pure water equipment wash the search?

- RO reverse osmosis membrane using time according to the general use of regional water quality or in front of the RO membrane filter replacement time, water a day in front of 5 litres of about half a year to replace the RO membrane filter, RO membrane can be used commonly 2 years no problem. The RO film is not well cleaned and should not be used.

- Q:Clean the cleaning parameters of the equipment

- Judge a ultrasonic cleaning machine general technical indicators as to stay ageing degree and resonant, impedance and impedance matching are already debugged before they go out, the key lies in you to do. Of course, the sound of ultrasonic cleaning machine and generator is now being silenced. The bonding mode of the oscillator is usually made of special cement, and the bolt fastening effect is good, but it is not suitable for maintenance. Frequency selection is cleaned according to the workpiece to decide, general material or on the surface is not very high, with 28 KHZ, more strict for cleaning, or had better choose high precision parts. This is because, the lower the frequency of the bubbles, the greater the when ultrasonic frequency is greater than 800 KHZ, there is no cavitation bubbles, this to be the effect of cleaning the surface of the cavitation corrosion is the lowest. In addition, the ultrasonic cleaning is the effect of the high pressure produced by an empty bubble in the instantaneous blast.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ss wire 410 for making scrubber,scoures

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords