Solid Color Decoration Grade High Pressure Laminates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of product:

Solid Color Decoration Grade High Pressure Laminates

General Information:

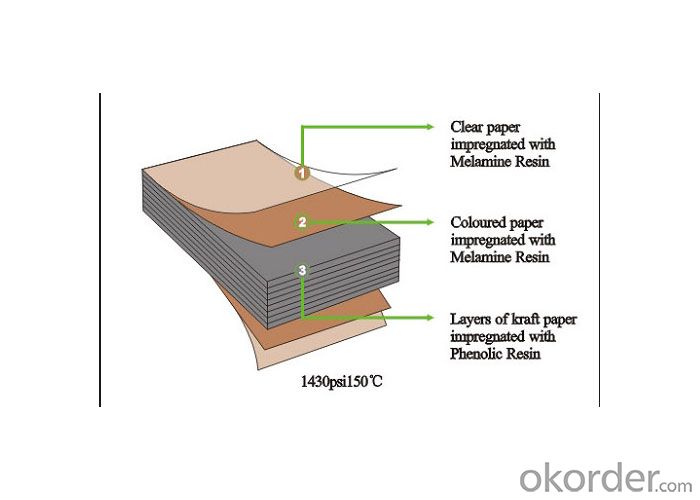

HPL(Decorative high-Pressure Laminate) is the fireproof material for decorative finishing, with variety of designs and colors、multiplicity surface texture and special performance, which is widely used in the interior decorative、furniture、kitchen cabinet、laboratory worktop、exterior wall and some other fields.

Specification:

4’*8’ (1220mm*2440mm) or customized size

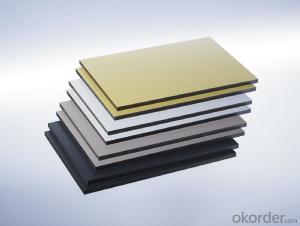

Color

Solid/plain color or customized color

If you need special color, please contact us

Surface Finishing

Glossy, Matt, Texture, Horizontal, Embossed and some other special surfaces.

Recommended Application

Compact laminate is suitable for interior horizontal or vertical surfaces where high strength, impact, water, and humidity resistance are required. Because of its inherent high strength, Compact sheets may be used as a structural material. Compact sheets can be drilled, routed, tapped, sanded, shaped and cut with standard carbide-tipped tooling. Compact sheets are available in two-sided decorative face; thicknesses ranging from 1.6mm to 25mm with black core. Fire retardant, Class I (A) grades are also available

Fabrication and Assembly

Limitations

Compact sheets are suitable for interior horizontal or vertical surfaces. Compact sheets, 1/4" (6.4mm) or less, are not recommended for adherence directly to plaster, gypsum board, or concrete. Do not use in areas exposed to temperature exceeding 275°F (135°C). Compact sheets are not recommended for exterior applications.

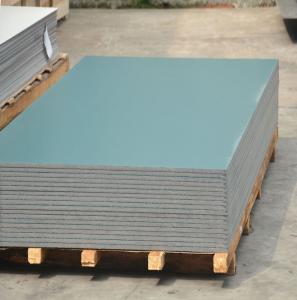

Storage

Compact sheets should be stored horizontally, with a caul board or other protective sheet placed on top to protect the material from possible damage. The material should be protected from moisture, and should never be stored in contact with the floor or an outside wall. Optimum conditions for storage are approximately 75°F (24°C), and 45% to 55% relative humidity.

Preconditioning

Compact sheets moves with changes in humidity, but less than standard high pressure laminate (HPL) sheet. Allow Compact sheets to acclimate for at least 48 hours to ambient conditions prior to fabrication. Optimum conditions are approximately 75°F (24°C), and at a relative humidity of 45% to 55%. Provisions should be made for the circulation of air around the material.

Substrates

If required, thinner variations of Compact sheets may be bonded to 45# density, industrial-grade particle board (ANSI A208.1-1999), medium density fiberboard (MDF), or hardwood-faced luan plywood. Softwood fir and other plywood have different dimensional stability and are not recommended as substrates. The substrates should be sanded smooth, clean, free of oil or grease, and uniform in thickness.

Adhesive

PVAc and rigid-set adhesives (urea, resorcinol) can be used to bond Compact sheets to substrates. Solvent-based contact adhesive can be used to bond laminate sheets to Compact sheets. Do not use water-based contacts for this application. Compact sheets greater than 1/4" (6.4mm) in thickness, can be applied as wall panels to the substrate using mechanical fasteners.

Assembly

Material, equipment, and workmanship should conform to the industry standard practices, conditions, procedures, and recommendations as specified by ANSI/NEMA LD3-2005. Compact sheets can be sawed, drilled, routed, and fabricated similarly to standard HPL. Carbide-tipped cutting tools are recommended. All inside corners of cutouts must be radiused as large as possible, 1/8" (3.18mm) minimum, to avoid stress cracking. The edges and corners should be routed, sanded, or filed smooth and free of chips or nicks.

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solid Color Decoration Grade High Pressure Laminates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords