SMC sheet, SMC roving with Glass Fiber Roving 2400 tex with Best Price/Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

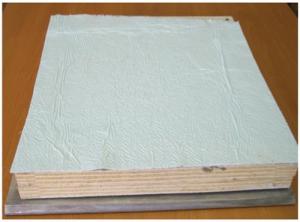

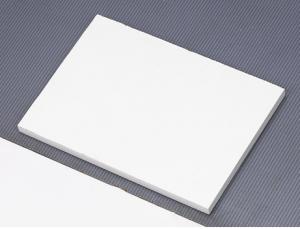

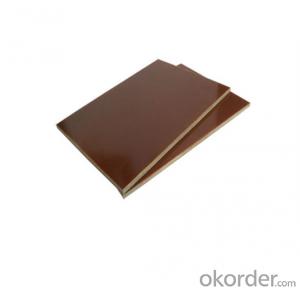

Introduction

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

l Excellent leak-proof electrical

l Low water absorption, good dimensional stability, war page small

l Reliable arc resistance and voltage withstand, high dielectric strength

Specification

Product name | Fiberglass Reinforced Polyester Corrugated Sheet |

Material | High-performance protective film, unsaturated polyester resin, fiberglass |

Layer | 1 layer |

Width | 900mm,930mm,1100mm |

Thickness | 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,3.0mm |

Length | 5800mm,11800mm or customized according to requirement of customers |

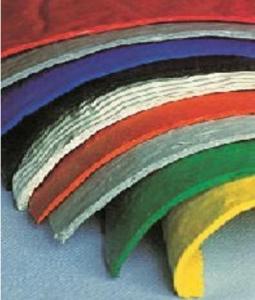

Color: | Clear, Red, Yellow, Green and opal |

Guarantee: | 10 years |

Certification: | ISO9001 SGS ROSH |

Delivery time | 5-7days(general) depend on the style and quantity |

detail features | 1.The light transmission It is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter. |

Advantage

l Absolute seal waterproof performance, corrosion resistance

l Beautiful appearance, long service life

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

2. Application in rail vehicle

SMC railway vehicles, window frames, bathroom components, seat, coffee table tops, SMC compartment wall and SMC roof

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

FACTORY

PACAKGE

- Q:Where is the difference between glass fiber reinforced plastic cable tray and SMC cable trough?

- Ordinary bridge, pultrusion process, resin, calcium powder, glass fiber and so on, the price is cheaper. Use on common cable

- Q:Who knows what is the process flow of FRP splicing water tank?

- The SMC single board with stripping stroke is used for polishing and examining the single board. After checking, the single board is pressed in place and the installation hole is put in storage. Then, the single plate, the glue bar and the stainless steel bracket are combined to form a water tank.

- Q:In recent years, what new materials have come into use in the automotive interior, or in the future?

- At present, LFT has become a new lightweight material for automobile which can challenge aluminum alloy and fiber reinforced thermosetting composites, and has a strong market competitiveness. According to reports, in recent years, the use of LFT made automotive products market share increased by about 15%, and maintain a strong upward trend, this phenomenon has aroused great concern among professionals in the industry.

- Q:What composite material is used for composite manhole covers?

- The composite well covers adopts unsaturated polyester resin as matrix and fiber reinforced thermosetting composite material, also called group molding plastics (DMC). It is made of pressing molding technology, and it is a new type of environmental protection type electric power cover plate.

- Q:Are SMC tablets harmful to the body? Our factory produces SMC. I have contact every day. Is there any odor that is harmful to my health?

- Now there are SMC ceiling, the wall products, many hospitals are in use, you can pay attention to professionals Li Laiyi's micro-blog. So, don't be afraid.

- Q:What material is the resin composite manhole cover made of?

- The raw materials for the composite cover of the colored resin composite cover are alkali free yarn, resin, low shrinkage, color paste, calcium powder, Magnesium Oxide and other additives, which are made by SMC high temperature molding without gluten sheets

- Q:SMC sheet pressing out the product is not bright, what is the reason?

- Different grades of tree ester use different raw materials, new glycol, propylene glycol content of higher tree ester, made out of sheet pressure product brightness is better, but the higher the cost.

- Q:What material is SMC? Can it replace ceramics? Can it be made into toilets, basins, urinals and so on?

- SMC composite is Sheet molding compound abbreviation, that is, sheet molding compound. The main raw materials are made up of GF (special yarn), UP (unsaturated resin), low shrinkage additive, MD (filler) and various auxiliaries. It first appeared in Europe in the early 1960s, and developed in the United States and Japan around 1965. At the end of 80s, China introduced advanced SMC production line and production process abroad.

- Q:What is polymer composite cable trench cover plate?

- Strictly speaking, should be unsaturated resin and glass fiber and other SMC sheet made of high temperature molding of the cover plate, there is no reinforcement inside, high strength.

- Q:Is the quality of the resin wall the same?

- From the material, divided into SMC sheet processing background wall and BMC group processing background wall, in which the SMC background wall high strength, board size can do relatively big, and BMC background wall can only do small size board.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SMC sheet, SMC roving with Glass Fiber Roving 2400 tex with Best Price/Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords