Single Stage Double Suction Split Casing Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Stage Double Suction Split Casing Water Pump for Pump Station

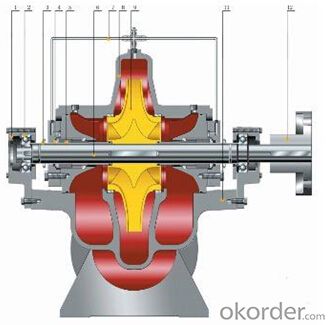

1.Structure of Single Stage Double Suction Split Casing Water Pump Description

The Single Stage Double Suction Water Pump is designed for pump station, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of the Single Stage Double Suction Split Casing Water Pump

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. Single Stage Double Suction Split Casing Water Pump Images

4. Single Stage Double Suction Split Casing Water Pump Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q:The flow of the pump will be reduced, the speed will change, the power of the motor will change?

- 1, this pump flow reduction is not the reason for speed. Because it is not matching the motor frequency conversion, the frequency of power supply unchanged, the motor speed will not change.2, the flow of water pump down, the reason may be that the impeller due to cavitation or wear and tear smaller, second, the gap between the impeller housing change, and the impeller plug foreign bodies, and some of the suction port leak.3, it is possible that the whole system resistance increases, so that the work point of the pump left.

- Q:I'm going to be purchasing a laboratory distillation kit here pretty soon, the kit includes everything I need for the setup but the condenser requires a water pump to circulate cold water around the coils. What kind of pump would you recommend for this purpose?

- The only thing you might need a pump for is if you are distilling/refluxing something and it is not all condensing before it reaches the end/top of the tube, resulting in vapor escaping. In that case you would use a bucket of ice water with a submersible pump.

- Q:How can the pump be stationary?

- 1, the pump bearing lubrication interruption, bearing burn.2, locking the rotor is jam.3, foreign body corrosion serious impeller lock.

- Q:I was recently driving and noticed my heat gauge in the red. I have a 1992 Honda Accord 4 door LX. When I opened the hood what appears to be water was all over the place. Is this the water pump or something else? I want to fix it this weekend so I was hoping for a better understanding of what it might be. I am aware of the labor involved with the water pump and removing the timing belts to get to it. Thanks a bunch in advance!

- it should,nt be water, it should be anti-freeze if it was leaking. if you meant anti-freeze the it don,t have to be the pump. it cold be a busted radiator hose, the radiator or 1 of the heater hoses leaking.

- Q:can this happen that pump is pressurizing system and no flow in suction.

- Hi, It seems to me your question is miss- worded or it simply flew over over my head. I'm intending the same project when time is there for it. I m a' machine builder by trade as also an oilfeild welder so tend to trust my plans about design. My answer to your question is you can't suck water from a plugged pipe except one tiny amount that would create a vaccum. My plan is an inline hot water pump(automotive type) to go to and from the water heater while the pluming route may have radiators or other heat transfer sourses like plane pipeat various points of the house return in an open pipe flow lie.Thermostate control hooked tothe electric motor that drives the water pump

- Q:Home water well is artesian, to holding tank. I am needing to replace my pump yearly. Inside of the pump is rusted, this causing a real loud whining sound before failure. Pump motor isn't failing, the inside of the pump ends up freezing loosing the ability to spin.Any suggestions as to why?

- Hi I was (now retired) in the pumping industry pumps for the kind of use you appear to be using them for were normally stainess steel or stainless steel and plastic. I would suggest you look at the Xylem ( a major supplier and installer of pumps) site. Regards John

- Q:An engineer is given the job of designing the water system for a tall building. He decides to locate the pumps at ground level and feed the entire building from there. If the top floor of the building is 236 m above ground level, what must the pressure be at pump level?

- 23.6 E5 Pa

- Q:Where is the water pump?How do i take it out, and replace it?

- Another thing that's good to do is disconnect the battery , plus be sure to check the quality and mixture of the coolant with a anti-freeze tester , also have a container handy so nothing falls on the ground bec anti-freeze is poison to animals if they drink it etc. Hope that helps and best of luck.

- Q:So, my husband and I bought a 1993 Chevrolet Corsica a couple of months ago. This weekend we took a trip that ended up being about 400 miles round trip. About 300 miles into our trip, the Check Engine light came on, but there was no noticable problem with the car, no overheating, no clanking or odd smells, the light went off about 2 minutes later. So we got it home, no problems whatsoever. My husband drove it to work this morning, and we were preparing to go to the store tonight in it, and we noticed a massive amount of radiator fluid under the car and the overflow bottle was empty. The leaking appears to be coming from the engine, and the antifreeze is running down one of the upper belts. Could this be a water pump problem? If so, what is the average cost to repair one (I know water pumps are relatively inexpensive, but we'll need to take it in to a shop). Does anyone have any idea? All replies will be greatly appreciated.

- we've a Jetta and the water pump went at 30,000 miles. Its meant to final plenty longer till the timing belt desires to get replaced. the reason they use plastic for the impeller is so if it fails it would not injury the timing belt. while the pump fails you may notcontinual the motor vehicle for any distance, the engine overheats, the warning lighting fixtures come on and thats it. in case you endured tocontinual you would be able to desire to doubtlessly grab the engine or a minimum of blow the top gasket and deform the top, those engines are all aluminum and can't stand to be overheated.

- Q:replaced one themostat, disconected lower unit twice look at the water pump everything looks fine but when lower unit was reconnected water pump would not work. not sure if asembled it wrong or forgot to d somthing. can someone help.

- check the water tube conection to make sure it is lined up and check to make sure the key is not sheered or missing from the water pump impeller

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Stage Double Suction Split Casing Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords