Shell NO.6 Pump Accessories in investment casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Made of 304 stainless steel products, mainly used in the impeller of the pump equipment. Products for OEM type, requires customers to drawings or samples for mold making, casting, machining and other processes.

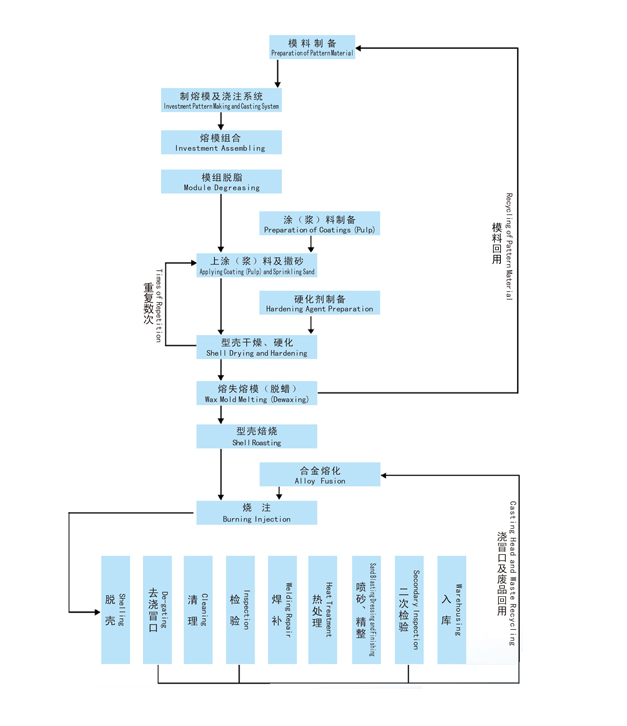

Process flow diagram:

Factory photos:

Taigang Investment Casting Co.,Ltd. (hereinafter referred to as Taigang) affiliated with Shandong Taishan Iron and Steel Group Co., Ltd., founded in 2000, covers an area of 10000 m2,has skilled workers and qualified engineers.Taigang is a member of China Foundry Association, had passed the ISO 14001:2004 EMS and ISO 9001:2008 QMS. With independent import and export right, Taigang sales products to South Korea, USA, Italy, Turkey, Spain, Japan and other countries.

Taigang is mainly engaged in the development and manufacture of precision castings, focuses on the research of water pump spare parts, Min impeller passage width is up to 4 mm.Taigang has an advanced precision casting production lines (silica sol lost wax process), an alloy casting lines (lost foam process), a CNC machining workshop (with output value of RMB 1.5 million yuan per month), aheat treatment workshop and many advanced test equipments,such as spectrometer, three-dimensional coordinate detector etc ,so as to have the ability to manufacture qualified castings. Now Taigang has the capacity of 1000 tons for precision castings per year, 1500 tons for heat resistant steel products per year, annual sales income adds up to 100 million yuan.

With the help of high quality and good reputation,Taigang wins high praise not only from the domestic clients,but also from abroad.Taigang is willing to cooperate with the vast number of foreign clients hand in hand and to achieve a win-win goal.

- Q:Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

- Q:Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q:What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q:What are the casting parts used to test shrinkage holes?

- 1. anatomy. It is easy to slack off by sawing and machining.

- Q:How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q:What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q:Why does the surface of stainless steel casting mirror mirror ripple?

- The surface can be improved by a little more than Xiasha

- Q:Heat treatment process and purpose of casting parts

- Objective: to stabilize tissues, eliminate or substantially reduce internal stress.

- Q:Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q:The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Shell NO.6 Pump Accessories in investment casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products