High Quality PP Biaxial Geogrid 30KN/30KN for Civil Engineering Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

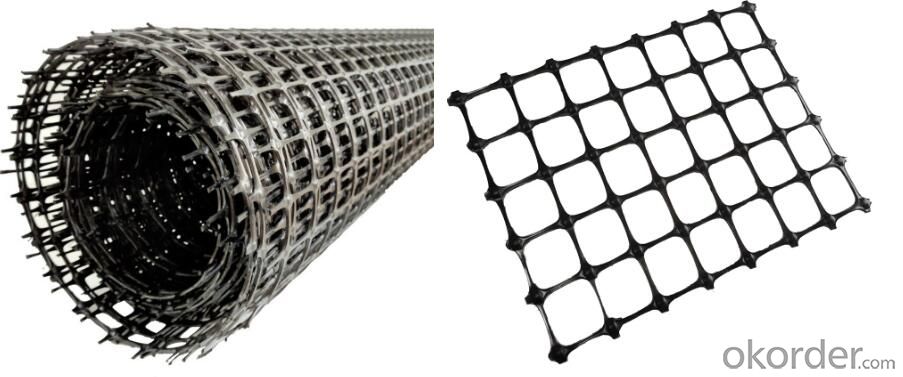

Introduction of Shandong High Quality PP Biaxial Geogrid 30KN/30KN:

PP Biaxial geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching, heating,

longitudinal stretching and transverse stretching.

Performance of High Quality PP Biaxial Geogrid 30KN/30KN:

---Homogeneous structure, low creep, anti-aging and resisting acid & alkaline.

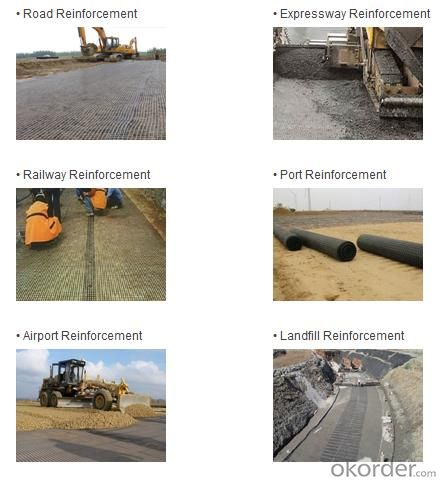

Applications of High Quality PP Biaxial Geogrid 30KN/30KN:

--Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement,

not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

--Used in highway, railway, port, airport and municipal project.

--Support in the recovery working face of coal mine and roadway in the coal mine.

Specifications of High Quality PP Biaxial Geogrid 30KN/30KN:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

- Q:Are geogrids suitable for reinforcing railway ballasts?

- Yes, geogrids are suitable for reinforcing railway ballasts. Geogrids provide additional support and stability to the ballast layer, preventing excessive deformation and improving load distribution. They help increase the lifespan of the railway track by reducing track settlement and improving overall track performance.

- Q:How do geogrids improve the stability of mechanically stabilized earth walls?

- Geogrids improve the stability of mechanically stabilized earth walls by enhancing the soil's tensile strength and preventing lateral movement. They act as a reinforcement, distributing the applied loads more evenly throughout the structure and reducing the potential for wall failure. Additionally, geogrids increase the frictional resistance between the soil and the wall, effectively increasing the overall stability and performance of the structure.

- Q:Are geogrids suitable for use in soil reinforcement for pipeline river crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline river crossings. Geogrids are high-strength synthetic materials that can be used to reinforce soil, providing increased stability and load-bearing capacity. They are commonly used in civil engineering projects, including pipeline river crossings, to prevent soil erosion and ensure the long-term integrity of the infrastructure.

- Q:How is a geogrid different from other geosynthetics?

- A geogrid is a type of geosynthetic that differs from other geosynthetics in its primary function and structural design. Unlike geotextiles or geocomposites that are primarily used for separation, filtration, or drainage purposes, geogrids are specifically designed to provide reinforcement and stabilization to soil and other materials. Geogrids are typically made of high-strength polymers and have a grid-like structure with open apertures, allowing them to interlock with soil particles and distribute loads more effectively. This unique design enables geogrids to enhance the mechanical properties of soils, increase their bearing capacity, and improve overall stability in various civil engineering applications.

- Q:What are the factors that affect the design of geogrid installations?

- There are several factors that can influence the design of geogrid installations. Firstly, the type and condition of the soil plays a crucial role as it determines the required strength and stability of the geogrid. The load that the geogrid will be subjected to is another important factor, as it dictates the necessary tensile strength and stiffness of the geogrid. Additionally, the slope and geometry of the project site need to be considered to ensure proper installation and performance of the geogrid. The climate and environmental conditions, such as temperature and moisture, can also impact the design, as they can affect the durability and long-term performance of the geogrid. Finally, the availability and cost of materials, as well as any relevant regulations or design standards, should be taken into account during the design process.

- Q:What is the meaning of 400g geotextiles /100g woven fabric

- Should be a layer of woven cloth PE film and a layer of geotextile. PE membrane and geotextile 400g

- Q:What are the benefits of using geogrids in construction projects?

- Geogrids offer several benefits in construction projects, including increased soil stability, improved load distribution, and enhanced overall structural integrity. These materials reinforce and stabilize the soil, preventing erosion and reducing the risk of slope failure. Geogrids also help distribute loads more evenly, reducing stress on the construction materials and extending their lifespan. Additionally, geogrids can be cost-effective as they often require less excavation and backfill material, saving time and resources during construction.

- Q:What is a civil grille

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid

- Q:Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- So I can give you a good price

- Q:Can geogrids withstand heavy loads?

- Yes, geogrids are designed to withstand heavy loads. They are made from high-strength materials and have a structural design that allows them to distribute and transfer loads effectively. Geogrids are commonly used in various applications such as road construction, retaining walls, and slope stabilization, where they provide reinforcement and increase the load-bearing capacity of the soil or aggregates they are installed with.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PP Biaxial Geogrid 30KN/30KN for Civil Engineering Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords