Rubber wood floor decking for outdoor made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

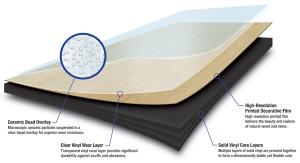

一. Structure of Rubber wood floor decking

Item | Rubber wood floor decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Rubber wood floor decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

三. Picture of Rubber wood floor decking

四. Rubber wood floor decking Specification

Name | Rubber wood floor decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Rubber wood floor decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q:How to eliminate the smell of plastic floor

- Put the floor outside the room put the taste, if not, for the sake of the child's health or not as good, consider replacing other things.

- Q:Our hostel is covered with plastic foam, so it's hot now

- Foam pad a quilt on a mat mat effect is very good

- Q:How to remove the plastic tiles on the floor tiles

- If is the antique tiles, polished tiles, glazed tiles of this kind of glazed tiles, mark generally do not penetrate into the glaze below, let dry directly after the knife can be scraped off, reoccupy wet dishcloth mark can be dried; if the effort can first with hot water to soak for a while in the seal surface, should be able to easy to wipe;

- Q:Plastic foam flooring is not a large mosaic floor.

- When the children grow up, the floor needs to be replaced. What is the relationship between the damage to the floor, and then you can re paint it. Tiling can also be placed on the floor, you can let the children split up, spell the demolition, not much impact on the floor.

- Q:Household PVC anti-static plastic floor

- Appearance like marble, with a good decorative effect. Applicable to the telecommunications, electronic industry, computer room, computer room, clean house and other requirements of purification and anti-static places.

- Q:Can I have a white mat?

- Wood flooring, acceptance and use of standard requirements, in the mat below paving a layer of plastic film, seam overlapping 20mm, and tape seal, in the geothermal conditions, even if the tape is moisture degumming, it is difficult to influence the floor, can more effectively prevent the harm of moisture on the floor. Therefore, it is necessary to lay plastic film in the geothermal environment.

- Q:How to tear off the plastic film on the floor tiles

- To be transferred to the factory, in order to prevent damage to the floor during the renovation, in the brick surface have done a deal with the pollution, the general polishing brick made of anti fouling wax

- Q:What a good brand of plastic flooring

- According to its material can be divided into hard, semi hard and soft (elastic) three

- Q:Wood floor moistureproof can use plastic film?

- The thickness swelling rate of water absorption is far less than the national standard. In addition, the special wear-resistant layer, decorative paper, the balance layer, can be a good substrate "closed" to ensure that the overall moisture-proof floor better

- Q:Dog feces in the plastic floor on how to clean, 84, washing powder, detergent are used, or brush off, how to do? What cleaning

- This is your sheet plastic floor, the sheet surface layer without UV treatment, suggested the use of plastic floor material, plastic floor can directly clean water, plastic flooring selection coil special PVC glue, stairs, wall with adhesive

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber wood floor decking for outdoor made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords