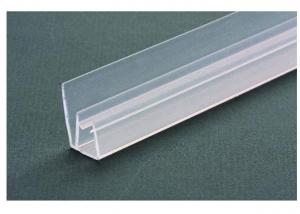

Rubber Washer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 Pieces pc

- Supply Capability:

- 100000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Rubber Washer

ISO9001 and TS16949 factory

Comply to Rohs, FDA, WRAS, NSF

Samples can be ready in 3-7days

Custom molded rubber washers, non-standard rubber washers, we made it according to your drawing.

1. It have 12 CNC machines, 3EDM machines, we can make over 100sets rubber mould per month.

2. Compression/transfer/injection(both hot runner and cold runner are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 15years experience in making rubber moulds, especially for rubber molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies.

7. Experience sales representative discuss with customer about the mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days.

Description of Rubber Washer

Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more)

Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance

Color: for rubber, usually black, for silicone, can be in any color as you want

Machine type: 50 to 400 tons

Molding service: we have our own mold workshop which have 12 sets CNC machines and provide compression/transfer/injection rubber molds

ISO9000 and TS16949 certificated factory

Mold/samples lead-time:

For prototype mold, usually in 7days

For mass production mold, usually in 2 weeks

For some special molds, can be in 30days, especially for some automotive rubber molds

Small orders are welcomed

- Q:What is the cause of the scaly skin on the tyres?

- Tire is one of the most important components of automobile, its main function is: all the weight support of the vehicle under car load transfer; traction and braking torque, ensure the adhesion of wheel; vibration and impact mitigation and absorption while driving, prevent the auto parts by the violent vibration and early damage to adapt to the high speed performance of the vehicle, and reduce running noise, ensure driving safety and handling stability, comfort and energy saving economy.

- Q:What is the density of rubber in car tires?

- If the raw materials, rubber, such as NR, SBR, BR, IIR, EPDM, etc., you can directly consult the literature search for related density;

- Q:What adhesive do you use for rubber seals on sunroof and glass panels?

- Owner Hello, as you said, it is recommended to use glass adhesive. Line maintenance technician for your answer, please refer to solve, I wish you a pleasant driving.

- Q:What's the effect of the shock absorber?

- Pressure top rubber, commonly known as a spring seat shock absorber, support, pressure, top glue role: 1. It is the material of plastic and rubber, the buffer, shock absorber, that is to say in the pressure angle intact in your some deceleration zone, he will be your car completely after landing in the tire will help you to trace the body feeling, especially good for comfort. 2. Sound generated by the tire and the ground tire is ridicule it to complete relief, when the tyre is rough ground bumps can reduce the direct impact on the car.

- Q:The rubber sleeve of the lower triangular support arm of the car is a little active. What harm does it continue to drive?.

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q:The tires are badly worn. Replacing tires means replacing rubber, not changing hubs

- The most used of wheel bearings of a car is twin row tapered roller or ball bearings. With the development of technology, the wheel hub unit has been widely used in cars. The range and use of wheel bearing units are increasing, and they have developed to the third generation. The first generation is made up of double row angular contact bearings.

- Q:How can you clean up the double sticky tape on the instrument panel?

- Previously encountered many owners in the dashboard with perfume and decorations are in addition to what the double glue down, recommend the use of warm water and wet towel, and rub slowly with any other cleaning agent can not, otherwise it will damage the instrument

- Q:How are the car tyres made?

- Plastic parts preparation processIn this connection, it is usually done in six steps to complete all the semi-finished rubber parts that make up the tire(1) section 1: extrusion;Add the material to the extruder head to extrude different semi-finished parts, such as tread, tread, triangle, etc..(2) section two: rolling;The raw material cord passes through the calender, and both sides of the cord are hung with a thin layer of adhesive material, which is finally processed into cords. The main material cord mainly uses nylon and polyester two kinds.(3) section three: bead forming;The bead ring is formed by winding a lot of steel wires. This kind of rubber used for bead has some special properties. When the vulcanization is finished, the glue and the steel wire can be tightly jointed together.

- Q:Is the smell of car tires harmful to the human body?

- There should be some, because he is rubber products, there is some harm

- Q:What are the patterns of electric tyres?

- The tire grip is mainly realized by the tread and ground contact theory, the slicks grip is the highest, but this concept is only limited to the dry land, as if on a slippery road, due to the slicks do not have drainage, will enable the vehicle to handle, safety.Large areas of rubber block design, to enhance the grip more helpful, this is different from the tire tread design, you can clearly see the difference. Generally speaking, emphasis on the movement of tire rubber block will be used in large area more, so as to improve the vehicle's grip, and to comfort the trend of tire pattern will be broken, the rubber block will also be small.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | Domestic Market Rubber and Plastic Products 61.8 Northern Europe Rubber and Plastic Products 2.7 North America Rubber and Plastic Products 10 Oceania Rubber and Plastic Products 0.9 Eastern Asia Rubber and Plastic Products 5.6 Western Europe Rubber and Plastic Products 19 |

| Company Certifications | ISO 9001-2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Rubber Washer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 Pieces pc

- Supply Capability:

- 100000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords