Roof Panel Roll Forming Machine on Steel Material Processing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roof Panel Roll Forming Machine on Steel Material Processing

1.Structure of Roof Panel Roll Forming Machine on Steel Material Processing

Roof Panel Roll Forming Machine on Steel Material Processing can rollform metal roofing sheet. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface.

Rollforming process: uncoiler, rollforming, cut to length.

Fully Automatic Control System with PLC.

Easy operation: Key in the length and quantity on the control panel.

One year warranty.

we also can do a custom roll forming machine, i.e. We can design the machine according to your specification and profile drawing.

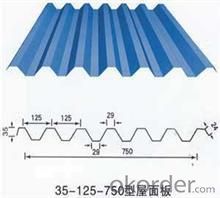

One roll forming machine only can produce one profile.The following profile drawing are some examples for your reference, which are widely used in various fields: industral factory, civilian building, warehouse, easy steel building, manufacturing, construction and have features such as nice appearance and durable.

2.Main Features of Roof Panel Roll Forming Machine on Steel Material Processing

1) Cheap cost

2) Small and convenient to transport even used in the construction site

3)Easy to operate

4)Computer control

3. Roof Panel Roll Forming Machine on Steel Material Processing Images

4. Roof Panel Roll Forming Machine on Steel Material Processing Specification

SHEET THICKNESS | 0.4 ~ 0.6 mm |

FORMING SPEED | 13 ~ 19 m |

ROLLER SHAFT DIA | φ50 ~ 70 mm |

ROLLER STATIONS | 14 ~ 20 |

MOTOR OUTPUT | 5.5 ~ 18.5 KW |

LENGTH x WIDTH | L 8.5 M |

SINGLE HEAD UNCOILER | 3.5 Ton |

5.FAQ of Roof Panel Roll Forming Machine on Steel Material Processing

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of many kinds of the construction machine and industry machines, who is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Could I have more technology date about your products?

SHEET THICKNESS | 0.4 ~ 0.6 mm |

FORMING SPEED | 13 ~ 19 m |

ROLLER SHAFT DIA | φ50 ~ 70 mm |

ROLLER STATIONS | 14 ~ 20 |

MOTOR OUTPUT | 5.5 ~ 18.5 KW |

LENGTH x WIDTH | L 8.5 M |

SINGLE HEAD UNCOILER | 3.5 Ton |

- Q:I'm a vegetarian who doesn't eat fish and I was just wondering what this means.

- Here okorder /

- Q:What is the best way to invent something? Like and industrial piece of machinery.?

- Most inventions are done by someone familiar with the industrial process itself. So I'd say the first thing you have to do is to have access to the process you want to improve. I get to invent things all the time. I work for a company that builds equipment for industrial and food processing companies. When a plant has a problem or a new process they call us we look at the process and design the equipment they need. Most of the time they have an idea of what they want or at least what they want to accomplish. Its not as much fun as you might think. Its a job. There are time constraints, cost constraints, process constraints all of which when balance don't leave you a lot of room to be that creative. At that point it then becomes a bunch of detail work, sizing the various components, drives, shafting, bearings, seals, etc. and developing shop drawings so the machine can be built. Its a good job but its a job. I would look for a metal fabrication company or a machine shop and work for them. I'd get the experience by working for someone else. Let them pay for your mistakes. You can't afford it.

- Q:would you be able to give reasons

- the general consensus is that the type of financing should match the lifespan of whatever you're buying. so for heavy machinery, these are typically long-term assets. as such, you want to use long-term debt (such as a long-term bank loan). ideally, the best financing is cash (you buy it outright). other alternatives would be to give the seller a corporate bond which promises them payments, etc. loan agreements are another option.

- Q:I'm in a tropical country, and heck, my whole life living here. I haven't experienced this kind of heat!I'm just a student, and because of that, I have no money to buy an ice cream maker.How can I make ice cream without a ice cream maker?

- Get 2 zip lock baggys. 1 gallon and 1 sandwich bag. U put ice cubes in the 1 gallon bag and then your choice of home made ice cream ingredients in the sandwich bag. Put the sandwich bag inside the 1 gallon bag... then... shake it for 10-15 minutes and bowww ice cream

- Q:What are the main considerations when choosing mechanical parts?

- The impact of ambient temperature, changes in ambient temperature will affect the expansion and contraction of parts; parts of the surface quality requirements and corrosion requirements; cost factors;

- Q:This is really our project to investigate, what's the significance of this and how it is done attractively? Yah, were going to defend it by the questions from the judges. What could be the possible questions? Does anyone have an idea? If you give me a detail answers, I will not refuse to give you 10 points.

- the significance would be it makes the farmer's easy for their work about that, you better study it

- Q:What kind of materials can EDM machine

- Theoretically, any conductive material can be machined with a wire EDM machine.

- Q:I forgot :DI think it's some sort of generator - I know there is some piece of equipment or machinery that converts the energy in power plants...Thanks in advance!!

- Generator is correct. Other names: alternator, dynamo. .

- Q:How to choose the material when doing mechanical design

- Usually in the design, the need to refer to similar products using the material, first rough classification: such as metal (ferrous metals, nonferrous metals, alloys, stainless steel, rare metals ...), non-metallic (rubber, plastic, wood,

- Q:it has for wheels and u can move around int it .... i can not think of its name!! PLEASE HELP =0

- what he said

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roof Panel Roll Forming Machine on Steel Material Processing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords