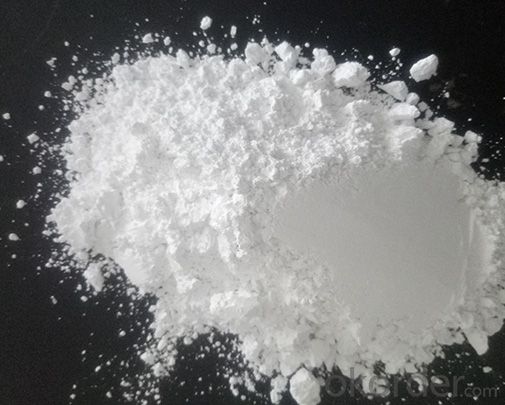

REFRACTORY CALCINED ALUMINA WITH LOW NA2O 0.04

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

· Shape: powder

· Material: Alumina

· Al2O3:99.2%min

· SiO2:0.05%max

· Fe2O3:0.04%max

· CAO:0.04%max

· NA2O:0.04%max

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: Calcined alumina

· Color: White

· Size:D50:3-5um/2-3um/1-3um

· BULK DENSITY:N/A

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q:Would you like to know if there are any enterprises in Mianyang that need fire-resistant materials?

- Big business needs to be usedIntroduce several big: Jiuzhou 208827 and Changhong

- Q:Are refractory materials and fireproofing materials the same?

- Refractories are generally used in the industry such as power plants, electric stove and industrial furnace. They include refractory bricks and insulation materials. Fireproof materials are generally used in building and they are fireproofing.

- Q:What's the commonly used refractory material for ladle?

- Commonly used types of refractory material for ladle are as follows: high-alumina brick, clay brick, magnesia-carbon brick, aluminum carbon brick, magnesia chrome brick, spinel brick, corundum brick, high alumina castables, aluminum silicon carbide carbon castables, refractory castables for ladles, magnesium castables, magnesia chrome spray coating, dry vibration materials, etc. Hope it's helpful for you!

- Q:Can anyone tell me what is the material of which the mould for refractory is made?

- Wooden mould will be used when refractories die is produced in small batch or composition of the refractory is complex. At the time of mass production, steel mould wil be used. The steel mould is a kind of imprint mold or cold mould. The cold mould, according to the working conditions of the products it manufactures, should have high hardness, strength, wear resistance, sufficient toughness and high hardenability. Commonly used steel types include high-carbon and low-alloy steel, high-carbon and high-chrome steel, chromium molybdenum steel and tungsten carbon chromium steel. You can choose them based on your needs

- Q:What are the applications of refractory in petroleum?

- It can be used in transportation of natural gas, filler of chemical equipment, security, insulation or even building materials.

- Q:The manufacturing technique of refractory material

- The major components of alkaline refractory material include magnesium oxide and calcium oxide. The commonly used alkaline refractory material is magnesia bricks. The magnesia bricks with 80%~85% magnesium oxide has good resistance to basic slag and slag and higher refractoriness than clay bricks and silica bricks. It is mainly used in open hearth, oxygen blowing of converter, electric furnace and smelting non-ferrous metal equipment and other high temperature equipment. Refractory materials applied on special occasions include high temperature oxide refractory materials such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, etc., refractory compounds such as carbide, nitride, boride, silicide and sulfide, etc., and high temperature composite materials, including metal ceramics, high temperature inorganic coating and fiber reinforced ceramics, etc. Consult and find reference for efractory materials production equipment, go to http://hi.baidu.

- Q:As for fireproofing material rock wool and glass wool, which one is better?

- As for fireproofing effect, the effect of rock wool is certainly better than glass wool , the highest temperature of rock wool is 1100 ℃, but the temperature of glass wool is only 600 ℃. In addition, if it's used in the external walls, then,unit weight of the glass wool is limited,and high unit weight can only be 60-90, but unit weight of rock wool can reach over 140, now external wall can't use glass wool, and only rock wool is A class fireproofing material. glass wool has lower thermal conductivity, rock wool has longer fiber length,as for the price, tons price of glass wool is more expensive than rock wool, but if it's acculated by square, square price of glass wool is cheaper than rock wool.

- Q:Who knows the new fireproof and thermal inuslation matertial?

- New fireproof and thermal inuslation matertial: foam concrete building blocks brick. The foam concrete building blocks brick is a new fireproof and thermal insulation material, with distinct advantages compared with the organic insulation material . Foam concrete can be used as wall materials, and it has a good self-insulation properties, so there is no problem of dropping off the outer insulating layer. A small part takes external wall exterior insulation, with mostly anchoring or dry hanging, which are not easy to fall off. Very few uses paste. Since the foam concrete and wall materials are of the same nature and strong adhesive, so it is also not easy to fall off.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

REFRACTORY CALCINED ALUMINA WITH LOW NA2O 0.04

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords