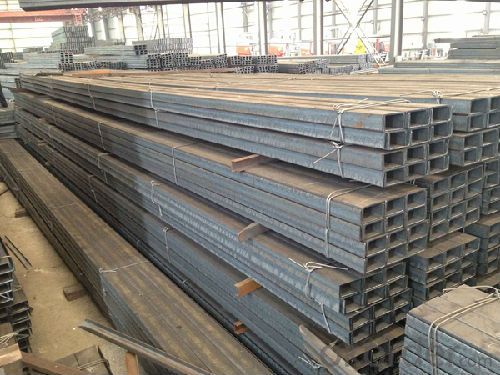

Q235 Hot Rolled Channel Steel With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Q235 Hot Rolled Channel Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235 Hot Rolled Channel Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Hot Rolled Channel Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

1. We are definitely specializing in manufacturing and supplying channel steel.

Standard: | GB |

Material/Grade: | Q235 |

Sizes: | 50mm to 280mm |

Sales Volume/Year: | 3000MT |

Destination Area: | Middle East, Africa, Southeast Asia |

2.Size, Length and Mass.

Size(mm) | Length(m) | Mass(Kg/m) |

180*68*7.0*10.5 mm | 6m, 12m | 20.174 kg/m |

180*70*9.0*10.5 mm | 6m, 12m | 23.000 kg/m |

Package & Delivery of Channel Steel:

The steel u channel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And steel u channel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

All in all, we could do in accordance with customer's request.

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:Can steel channels be used for balcony supports?

- Yes, steel channels can be used for balcony supports. Steel channels are commonly used in construction and engineering projects for their strength and durability. They provide excellent support for structures, including balconies. When properly designed and installed, steel channels can effectively bear the weight and load of a balcony, ensuring its stability and safety. It is important to consult with a structural engineer or a professional contractor to determine the appropriate size and specification of the steel channels required for the specific balcony design and load requirements.

- Q:Can steel channels be used in the chemical industry?

- Indeed, the chemical industry finds steel channels to be highly applicable. With their remarkable strength, durability, and corrosion resistance, steel channels are frequently utilized across multiple industries, including the chemical sector. They serve as essential elements for structural support, while also being instrumental in constructing platforms, walkways, and equipment supports within chemical plants. Furthermore, steel channels exhibit exceptional resilience to both high temperatures and pressures, rendering them ideal for chemical processing and transportation. In summary, steel channels prove themselves to be an adaptable and dependable option for the chemical industry.

- Q:Are steel channels suitable for use in industrial settings?

- Yes, steel channels are often used in industrial settings due to their strength, durability, and versatility. They provide structural support and can be easily integrated into various applications such as building frames, machinery, and conveyors. Additionally, steel channels offer resistance to corrosion, fire, and extreme temperatures, making them highly suitable for industrial environments.

- Q:How are steel channels protected against corrosion?

- There are multiple ways to protect steel channels from corrosion. One popular method involves applying a protective coating, such as paint or epoxy, to the surface of the channels. This coating acts as a barrier between the steel and the corrosive elements in the environment, reducing the risk of corrosion. Another approach is to use galvanization, which entails coating the steel channels with a layer of zinc. This zinc coating serves as a sacrificial layer, corroding instead of the steel when exposed to corrosive elements. This technique prolongs the lifespan of the steel channels and provides long-term corrosion protection. Additionally, cathodic protection can be utilized to safeguard steel channels. This method involves applying an electric current to the channels, neutralizing the corrosive reactions that lead to corrosion. Cathodic protection is often combined with other protective measures to enhance corrosion protection. Regular maintenance and inspection play a crucial role in protecting steel channels against corrosion. Identifying and promptly addressing any signs of damage or deterioration is essential to prevent further corrosion. Regularly cleaning the channels and removing contaminants or debris can also minimize the risk of corrosion. In summary, a combination of protective coatings, galvanization, cathodic protection, and regular maintenance effectively safeguard steel channels against corrosion and extend their lifespan.

- Q:What are the safety considerations for working with steel channels?

- To ensure the well-being of individuals involved in the process of working with steel channels, it is important to take several safety considerations into account. 1. Personal Protective Equipment (PPE): It is crucial to wear the necessary PPE, which includes safety glasses, steel-toed boots, gloves, and a hard hat. This equipment provides protection against potential hazards such as falling objects, sharp edges, and sparks. 2. Lifting and handling: Steel channels can be heavy and unwieldy. Therefore, it is essential to use proper lifting techniques. This involves bending the knees and using the legs to lift instead of the back. For heavier channels, mechanical lifting devices like cranes or forklifts should be used. 3. Secure storage and stacking: When not in use, steel channels should be stored in a dedicated and stable area. Stacking should be done with care, ensuring that the channels are properly supported and won't topple over. 4. Precautions for cutting and welding: Proper ventilation is crucial while cutting or welding steel channels to prevent inhaling fumes and gases. Adequate ventilation systems should be in place, and workers should wear the appropriate respiratory protection when necessary. To prevent sparks from igniting nearby flammable materials, fire-resistant curtains or shields should be used. 5. Sharp edges and burrs: Steel channels can have sharp edges or burrs that may cause cuts or injuries. Before working with the channels, it is important to inspect and remove any sharp edges or burrs. Wearing cut-resistant gloves can provide an additional layer of protection. 6. Tripping and slipping hazards: Steel channels left unsecured on the ground can create tripping hazards. Workers need to ensure that the work area is free of obstructions or debris that could cause slips or falls. 7. Training and supervision: All individuals involved in working with steel channels should receive proper training and supervision. This includes understanding correct handling techniques, safety protocols, and emergency procedures. Regular safety meetings and inspections should also be conducted to maintain a safe working environment. By considering these safety measures when working with steel channels, the risk of accidents, injuries, and material damage can be significantly reduced, creating a safer and more productive working environment.

- Q:What does channel C20 mean?

- Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures and fixed plates, cabinets, etc., and channel steel is often used in conjunction with i-beam.

- Q:Can steel channels be used for stair treads?

- Yes, steel channels can be used for stair treads. Steel channels provide strength and durability, making them suitable for supporting the weight and traffic of stair treads. Additionally, steel channels can be easily fabricated and customized to meet the specific requirements of staircases.

- Q:Channel 10 is calculated, if the price per metre is calculated

- On the market, the sale of 10 channel steel, a lot less than the national standard weight, the general negative difference in 5% within the standard. Depending on your use requirements, the maximum negative difference may be as high as 30%.

- Q:How do steel channels contribute to the overall durability of a railway bridge?

- The durability of a railway bridge is improved by steel channels in various ways. Firstly, they offer structural support and strength, enabling the bridge to withstand heavy loads and forces. These channels are designed to evenly distribute the weight of the train across the bridge, preventing localized stress points that could cause structural failure. Furthermore, steel channels are highly resistant to corrosion and rust, which is essential for a railway bridge exposed to different weather conditions and environmental factors. This resistance to corrosion ensures the bridge remains strong and durable over time, reducing the need for frequent maintenance and repairs. Another contribution to durability is the ability of steel channels to absorb and dissipate energy. If there is a sudden impact or excessive vibrations from passing trains, the steel channels can absorb and disperse the energy, minimizing the risk of damage or structural failure. Moreover, steel channels are frequently used in constructing railway bridges due to their fire-resistant properties. Steel has a high melting point, making it less likely to deform or collapse in the event of a fire. This enhances the overall safety and durability of the bridge since it can withstand extreme temperatures for an extended period. In conclusion, steel channels are crucial for enhancing the durability of a railway bridge. They provide structural strength, corrosion resistance, energy absorption, and fire-resistant properties. Their contribution ensures the bridge's longevity and safety, allowing it to effectively support the transportation of trains and passengers for many years.

- Q:What are the advantages of using hot-rolled steel channels?

- Some advantages of using hot-rolled steel channels include their high strength-to-weight ratio, durability, and cost-effectiveness. Hot-rolled steel channels are able to support heavy loads while minimizing material weight, making them ideal for structural applications. Additionally, their hot-rolled manufacturing process ensures a consistent and uniform shape, resulting in accurate and easy installation. Furthermore, hot-rolled steel channels are often more affordable compared to other materials, making them a popular choice for various construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q235 Hot Rolled Channel Steel With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords