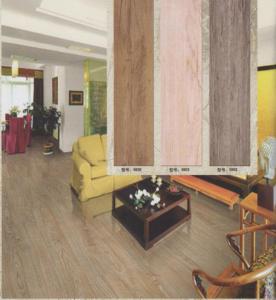

PVC Floor Sheet, Best Price PVC Flooring, PVC Floor For Children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specifications:

Material | PVC virgin material |

Thickness | 2mm, 3mm, 8mm |

Wear layer | 0.5mm |

Width | 1.5m |

Pattern | Customized design |

MOQ | 1 sqm |

2.Certifications: CE,ISO14001, ISO9001,CTI.

3.Features:

1) PVC material,eco-friendly,safe,soft,comfortable

2) Super wear resistance,durable,long service time

3) Customized design, personalized cartoons

4) An-slip,injury prevention

5)Shock proof and noise absorption

6) Easy installation and cleaning

7) Play function and educational.

8) Waterproof,moistureproof,anti-bacterial,fire resistance.

4.Application:

Kindergarten,school, parent-child center, children study/sleeping rooms,children activity/ library/ health recovery and training rooms,house corridors, halls and other grounds for children living and studying.

- Q:floor hockey

- Moving the ball with you're stick in a quick back to back motion while maintaining control. LITY - I played floor hockey at the Y a few years back and the kid dribbled his dinner all over the floor from the excitement

- Q:Need to find other cleaner than pergo's brand cleaner that is unavailable to get floors clean and not leave foot prints behind after washed . also the stickiness always left behind

- Have you ever tried the Swiffer Wet-Jet with their anti-bacterial, deodorizing solution? I use it for all types of floors..even the wood. It's either that...or get yourself a Sharp steam mop if it's a large area to clean...worth the expense and floors' germs are killed with the steam.

- Q:Hi im doing beauty homework please can someone help?what type of flooring would be suitable for a beauty salon and why????thanks i appreciate any help!

- Epoxy Terrazzo may be a good choice. Many color choices, no grout lines or grooves for hair or spills to creep in. Easy care, looks clean which you definitely want your customers to associate your business with.

- Q:I am laying a three part epoxy resin flooring to a factory floor. Any tips?????

- Normally an epoxy resin floor is 2 part epoxy with a third component is color flacks that are hand spread over the resin as it is spread on the floor.. I am assuming you are going to apply this to a concrete floor. Mix the resin according to the instructions on the box or container it comes in. Follow all instructions that come with the product relative preparing the floor, such as cleaning up dirt and grease. once the resin is mixed in a large enough sized container. You may want to apply the resin around the outside edges of the floor about 5 or 6 inches with a throw away brush. spread the resin on the rest of the floor with a paint rollers. Do relatively small sections at a time and sprinkle the color flakes over each section as though you were broadcasting grass seed or ice melt. You will probably find that you will need 2 coats of the resin to cover the floor well.

- Q:I intend on putting vinyl flooring over top.Plywood or leveler?

- I would not use plywood over concrete, it wil split, crack and warp because of moisture. Use advantek sold at Lowes or lumber yards, it is moisture resistant engineered plywood. The seal the joints, before you put down your tile.

- Q:I have just purchased laminated flooring. It is called KR Inspiration Treehill Gunstock Oak. Does anyone have information about this type of flooring?

- laminate flooring consists of a wood composite core. then it has a computer generated graphic applied over the wood core. then a melamine resin wear surface is added. if its a click board only two companies hold the patent to make the board and all companies buy from thees two companies. the price difference comes from the quality of the picture, the number of different pictures a run will contain, and the ac rating on a scale of 1 to 4. to install it you must let it sit in the room for 72 hrs. then you must leave an expansion joint around the whole room usually a quarter inch. all edges must be covered with molding or trim. door jams must be undercut. and you must use an underlayment foam. if you need more help feel free to contact me.

- Q:Floor material The choice of thickness As well as the installation of the precautions? Not very grateful! More

- In general, for all the wood flooring, are not suitable for heating, because the thermal expansion and contraction and heating effect, the wood floor of the water will be different from the environment, over time, causing damage to Cao Cao 丨 meter attack intestinal plate Warping, cracking, cracks

- Q:I was attempting to replace my linoleum floor, I discovered a black tar adhesive under the old Linoleum, When I tried to pull the old Linoleum up, The floor started to splinter!, There seems to be a top thin layer of wood over the sub-flooring?, This is coming up with the Linoleum, Should I just leave the old Linoleum like it is and put the new linoleum over it?, Or should I go thru hell and high water and replace the entire floor???

- Rip it all up! better to start fresh. Flooring installers say Better to start with a fresh floor rather than putting **** on top of ****! Sorry for the swear but that's the saying! In other words if the floor is bad where you would be putting a new one, the new one you put down will be bad too! Besides, your making the floor higher. Then when the next person that wants to change the floor has double the work! And so-on and so-on!

- Q:is there any chemical/solution to remove acid stains from floors?please help me.

- No, the acid has eaten away the finish.

- Q:I'm in the upstairs area of a building and when I lift weights the floors squeak horrindously. I'm only here for a few weeks and I'd like to know if there's a mat or something that I can put on the floor.

- Ladonna is right, sub-floor is loose needs to be screwed back down no matter what pads you buy it will still squeak, Generally though if its carpeted it has to come up or wood over layer floor has to come up to fix it You have to put the screws into the joists about every 6-8 inches if you can't locate the joists you will sink many screws and do nothing to fix it! hope it helps Lr

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Floor Sheet, Best Price PVC Flooring, PVC Floor For Children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products