PVC Electrical Tape for Wholesales Hot Selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

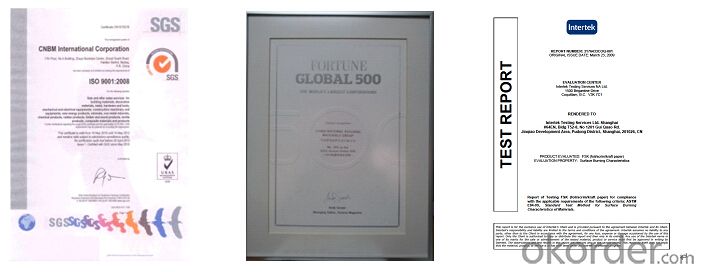

• World Top 500 Enterprises

• Resistance to cold, heat and aging

• Best quality and competitive price

• SGS&ISO9001, Customs Grade AA

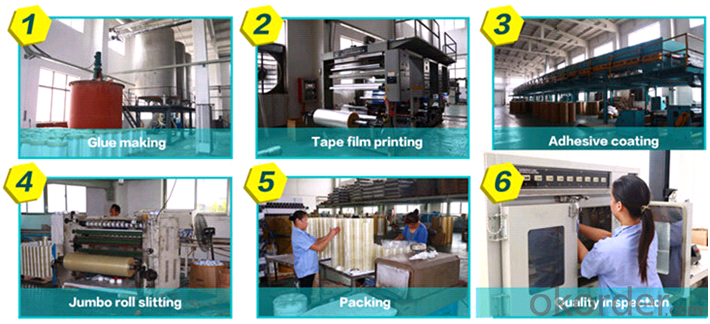

The PVC Electrical Tape is of PVC film as the carrier, coating with rubber based adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to electrical products.

The thickness of the tape can be customized.

PVC Electrical Tape is ideal for insulating, protection and color coding of electrical wires; may also be used as harness tape in automotive industry.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

| Standard size | 19mm*10m, 19mm*20m, 1.25m*10m, 1.25m*33m, etc |

| Thickness (micron) | 110 |

| Color | All Color Available |

| Adhesion to steel (N/cm) | 1.5 |

| Tensile Strength (N/cm) | 18 |

| Elongation at break (%) | 190 |

| Dielectric breakdown (V) | 600 |

| Flame Resistance (s) | <5 |

| Packing | Carton |

| Delivery | With 10-25days after receiving deposit |

| Payment | T/T & LC |

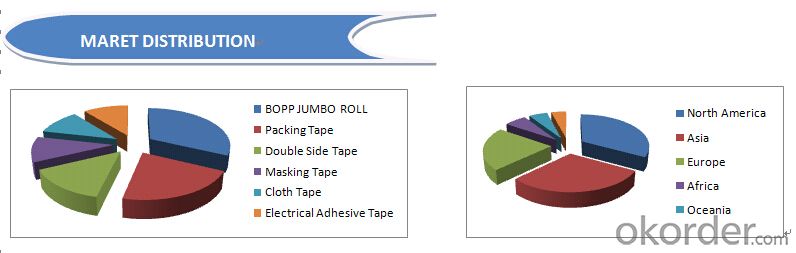

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

You are welcome to contact me at any time and visit the factory in China!

- Q:Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. Packaging tape is designed to have a strong adhesive that adheres well to various surfaces, including foam and bubble wrap. By applying packaging tape to the edges or seams of foam or bubble wrap, you can securely seal and protect your items during shipping or storage. It is important to ensure that the tape is applied properly and firmly to provide a tight seal and prevent the foam or bubble wrap from coming loose.

- Q:Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can definitely be used for sealing retail or product packaging. Packaging tape is specifically designed for sealing boxes and packages, providing a secure and durable seal. It is commonly used in various industries, including retail, e-commerce, and product packaging. Packaging tape is typically made of strong adhesive material, ensuring that the package remains sealed during transportation and handling. It is easy to use, as it can be applied quickly and efficiently. Additionally, packaging tape is available in different sizes and strengths, allowing it to meet the specific needs and requirements of different types of retail or product packaging. Overall, packaging tape is a reliable and effective option for sealing retail or product packaging.

- Q:Are there specific brands of packaging tape that are recommended?

- Yes, there are specific brands of packaging tape that are commonly recommended for their quality and reliability. Some popular and highly regarded brands include Scotch, Duck, 3M, Gorilla, and Uline. These brands are known for producing packaging tapes that have strong adhesive properties, excellent durability, and the ability to securely seal boxes and packages. Additionally, these brands often offer a variety of options such as different widths, lengths, and types of tape (such as clear, colored, or reinforced) to suit various packaging needs. However, it is always recommended to consider the specific requirements of your packaging task and read customer reviews before choosing a brand of packaging tape.

- Q:How does packaging tape adhere to surfaces?

- Packaging tape sticks to surfaces by utilizing adhesive materials that are typically made from synthetic rubber or acrylic-based substances. These materials are specifically engineered to possess a strong bonding capability with a variety of surfaces, including cardboard, plastic, and metal. The adhesive on packaging tape functions by establishing a connection between the tape and the applied surface. When pressure is exerted on the tape, the adhesive substance spreads out and establishes contact with the surface. This contact enables the adhesive to interact with the molecules of the surface, resulting in the formation of a bond through intermolecular forces. The most commonly employed type of adhesive found on packaging tape is known as pressure-sensitive adhesive (PSA). PSA is specifically formulated to adhere to surfaces with minimal pressure. Upon the application of pressure, the adhesive substance flows and conforms to the surface, ultimately creating a robust bond. Furthermore, the adhesive on packaging tape is designed to withstand various environmental factors such as temperature, humidity, and moisture. This ensures that the tape remains firmly adhered to the surface, even in challenging conditions. In conclusion, packaging tape adheres to surfaces by utilizing adhesive materials, typically synthetic rubber or acrylic-based. These adhesives establish a bond between the tape and the surface through intermolecular forces, allowing the tape to securely stick.

- Q:Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q:Can packaging tape be used for sealing gardening or outdoor equipment?

- Indeed, gardening or outdoor equipment can be effectively sealed using packaging tape. Specifically engineered to securely seal boxes and packages, packaging tape proves itself as an excellent option for sealing outdoor gear like gardening tools, outdoor furniture, and other equipment. Its robust and long-lasting seal is capable of enduring outdoor conditions, including moisture and temperature fluctuations. Nevertheless, it is worth mentioning that if the equipment or packaging tape is expected to endure harsh weather conditions or prolonged outdoor usage, opting for specialized outdoor or weather-resistant tape would be more suitable to ensure enhanced durability and longevity.

- Q:Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience.

- Q:Can packaging tape be used for sealing packages with breakable items like ceramics?

- Indeed, packaging tape possesses the ability to seal packages containing delicate objects such as ceramics. Nevertheless, it is crucial to guarantee the tape's proper application to offer sufficient support and safeguard the fragile items. In conjunction with employing packaging tape, it is advisable to incorporate supplementary protective materials like bubble wrap or foam padding to cushion the ceramics and reduce the likelihood of harm during transportation.

- Q:How do I choose the right packaging tape for my needs?

- Choosing the right packaging tape for your needs can be an important decision to ensure your packages are securely sealed during transit. Here are a few factors to consider when selecting the appropriate packaging tape: 1. Strength and durability: Consider the weight and nature of your packages. If you are shipping heavy or bulky items, opt for a tape that offers high tensile strength and can withstand rough handling. Look for tapes made from materials like fiberglass or reinforced with polyester fibers. 2. Adhesive type: Different packaging tapes use various types of adhesives. Acrylic adhesive is common and offers a good balance of performance and affordability. For more challenging surfaces or extreme conditions, consider hot melt adhesive, which provides superior bonding strength. Additionally, water-activated tape, also known as gummed paper tape, is a great option for added security as it forms a permanent bond when moistened. 3. Width and length: Determine the appropriate width and length of tape based on the size of your packages. Thicker tapes are generally more durable, while longer rolls may be more cost-effective for high-volume packaging. 4. Transparency and aesthetics: If you require your packages to have a professional appearance or if you need to see the contents of the package easily, opt for a clear or transparent packaging tape. However, if appearance is not a concern, choosing a colored tape can help with easy identification or branding purposes. 5. Environmental considerations: If you are conscious of your carbon footprint, look for packaging tapes made from eco-friendly materials or those that are recyclable. Some tapes are also water-based, solvent-free, or made from renewable resources, making them a greener choice. 6. Dispenser compatibility: Consider the type of tape dispenser you have or plan to use. Make sure the tape you choose is compatible with your dispenser, as some tapes require specific types of dispensers. 7. Cost: Finally, compare prices and consider your budget. However, keep in mind that sacrificing quality for a lower price may result in inadequate tape performance and potential package damage. By considering these factors, you can make an informed decision and choose the right packaging tape that best suits your needs, ensuring your packages arrive securely and intact.

- Q:Does packaging tape have a specific adhesive strength?

- Packaging tape possesses a specific adhesive strength, indicating its ability to adhere to surfaces effectively. This strength is commonly quantified in ounces per inch (oz/in) or pounds per inch (lb/in). Several factors contribute to the adhesive strength of packaging tape, including the adhesive type, tape thickness, and backing material quality. To meet distinct requirements, various types of packaging tape offer different adhesive strengths, suitable for lightweight parcels or robust shipments. When selecting packaging tape, it is crucial to consider the intended application and package weight to ensure an appropriate adhesive strength match.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Electrical Tape for Wholesales Hot Selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products