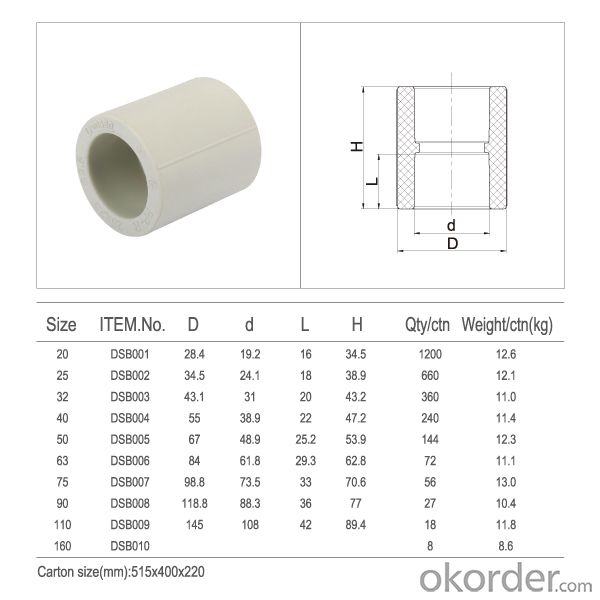

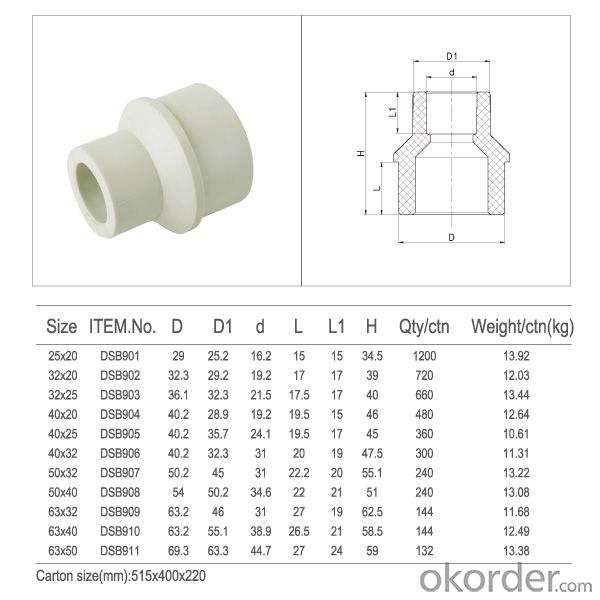

PPR Male & Female Coupling and Equal & reduced coupling

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 1000PCS

- Supply Capability:

- 100000 1000PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Standard:GB/T 5836.1-2006,ISO9001:2000.ISO14001

Health, non-toxic, can be used for pure water, drinking water pipeline system, the product is a green building

materials

Unique and unrivaled German connection technique, convenient and reliable installation, low construction expenses

Lightweight, convenient to transport and handle, good for labor-saving

Beautiful colors and excellent design ensure suitability for both exposed and hidden installation

Recyclable, environment-friendly, accords with GBM standards

Long time life: the pipeing system under normal use life of up to 50 years.

Specification

Packaging & Shipping

Packaging Details: Carton,bags with inner small PE bags. We can also pack as you need.

Delivery Detail: Shipped in 25 days after payment

FAQ

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

Please feel free to leave us message if you have any question about us and our products.

- Q:Are plastic pipe fittings resistant to sewer gas?

- Yes, plastic pipe fittings are generally resistant to sewer gas. They are commonly made from materials such as PVC and ABS, which are highly durable and have airtight seals that prevent the escape of sewer gas.

- Q:Are the elbow and three - pipe fittings installed in the water supply and drainage pipes included?

- Indoor heating plastic pipe, aluminum-plastic composite pipe, stainless steel pipe, copper pipe installation project, the pipeline joint parts as materials, according to design drawings to determine the number and loss of 1% of the cost of materials shall be calculated separately.

- Q:Are plastic pipe fittings resistant to thermal expansion and contraction?

- Yes, plastic pipe fittings are generally resistant to thermal expansion and contraction. Unlike metal fittings, plastic materials have a greater ability to expand and contract without undergoing significant dimensional changes or structural damage. Additionally, plastic pipes and fittings have lower thermal conductivity, which further helps in minimizing the effects of temperature fluctuations. However, it's important to consider the specific type of plastic used in the fittings, as different materials may exhibit varying degrees of resistance to thermal expansion and contraction.

- Q:Can plastic pipe fittings be used for stormwater management?

- Yes, plastic pipe fittings can be used for stormwater management. Plastic pipe fittings are commonly used in stormwater management systems due to their durability, flexibility, and resistance to corrosion. They offer a cost-effective solution for managing stormwater runoff and can be easily installed and maintained.

- Q:How do plastic pipe fittings compare to copper fittings?

- Plastic pipe fittings and copper fittings have their own distinct advantages and disadvantages. While copper fittings have been widely used for many years and are known for their durability and reliability, plastic fittings have gained popularity due to their cost-effectiveness and ease of installation. Copper fittings are known for their resistance to corrosion and high pressure, making them suitable for demanding applications such as plumbing systems. On the other hand, plastic fittings are lightweight, non-corrosive, and resistant to chemicals, making them ideal for applications that require flexibility and easy handling. Ultimately, the choice between plastic and copper fittings depends on the specific requirements of the project, budget constraints, and personal preferences.

- Q:Can plastic pipe fittings be used for oil and gas pipelines?

- No, plastic pipe fittings are not suitable for oil and gas pipelines. These pipelines require materials that can withstand high pressure, extreme temperatures, and corrosive environments, which are characteristics that plastic fittings do not possess. Metal fittings, such as steel or iron, are commonly used in oil and gas pipelines due to their strength and durability.

- Q:Can plastic pipe fittings be used for irrigation of golf courses?

- Yes, plastic pipe fittings can be used for irrigation of golf courses. Plastic pipe fittings are commonly used in irrigation systems due to their durability, affordability, and resistance to corrosion. They are compatible with various types of pipes and can effectively distribute water to the desired areas on a golf course. Additionally, plastic fittings are easy to install and maintain, making them a suitable choice for irrigation systems in golf courses.

- Q:How do plastic pipe fittings compare to fiberglass fittings?

- Plastic pipe fittings and fiberglass fittings have their own advantages and disadvantages. Plastic fittings are generally more affordable and easy to install, but they may not be as durable or resistant to certain chemicals as fiberglass fittings. On the other hand, fiberglass fittings are known for their superior strength and resistance to corrosion, making them a preferred choice in harsh environments. Ultimately, the choice between plastic and fiberglass fittings depends on the specific application and the level of durability and chemical resistance required.

- Q:What are the common installation methods for plastic pipe fittings?

- The common installation methods for plastic pipe fittings include solvent welding, threaded connections, and compression fittings.

- Q:Can plastic pipe fittings be used for wastewater disinfection systems?

- No, plastic pipe fittings are not suitable for wastewater disinfection systems. These systems require materials that can withstand harsh chemicals and high temperatures, which plastic fittings may not be able to handle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Male & Female Coupling and Equal & reduced coupling

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 1000PCS

- Supply Capability:

- 100000 1000PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords