ppgi/Hot Sale Building and Electrical Steel Coil/Corrugated Roofing Sheets/ Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Hot Sale Building and Electrical Steel Coil/Corrugated Roofing Sheets/ Galvanized Steel Coil

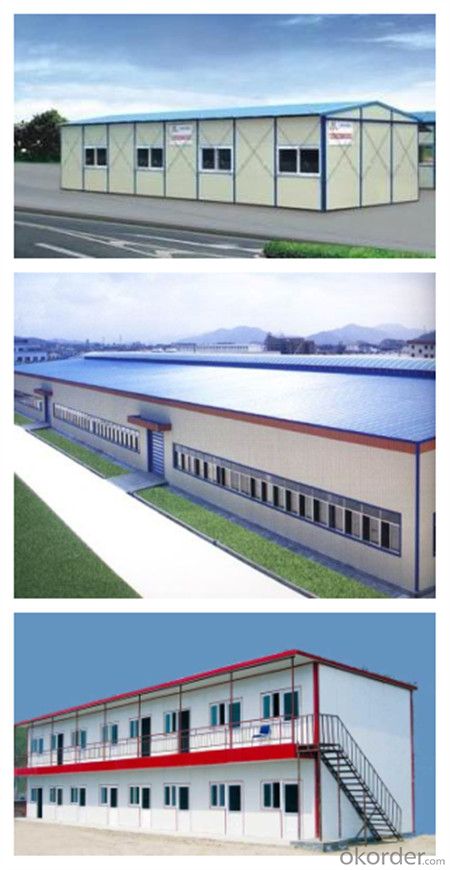

1. Application of Building and Electrical Steel Coil:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

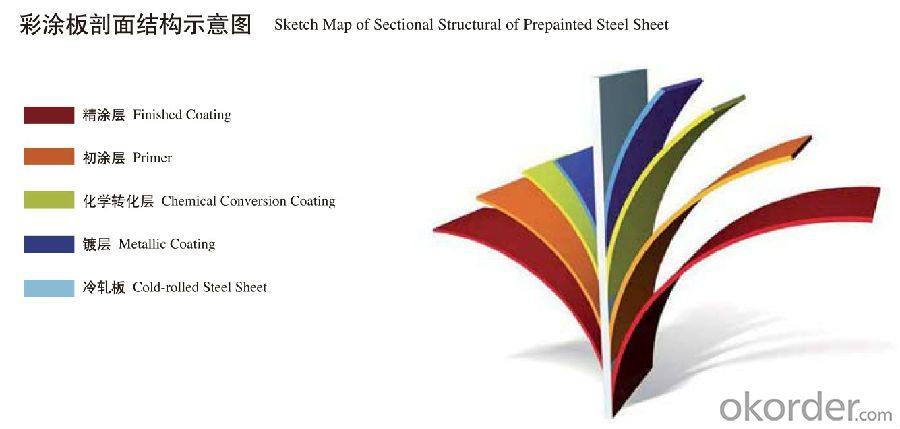

2.Features of Building and Electrical Steel Coil:

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Building and Electrical Steel Coil :

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

4. Building and Electrical Steel Coil image:

APPLICATION:

PROUDUCTION LINE:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:What are the common methods of storing steel coils in warehouses?

- There are several common methods for storing steel coils in warehouses, depending on the size and weight of the coils, as well as the available space and resources in the warehouse. Here are some of the most commonly used methods: 1. Block stacking: This method involves stacking the steel coils directly on top of each other, forming a block. The coils are typically aligned in rows and columns, with wood or rubber blocks placed between the layers to provide stability and prevent damage. 2. Racking systems: Racks are often used to store steel coils in warehouses. There are various types of racks, including cantilever racks, coil racks, and structural racks. These racks provide a structured system for organizing and storing the coils, allowing for easy access and efficient use of space. 3. Coil cradles: Coil cradles are a type of storage equipment specifically designed for steel coils. They consist of a series of cradles or saddles that securely hold the coils in place. These cradles can be stacked on top of each other to maximize vertical space utilization. 4. Coil pads: Coil pads are flat platforms made from materials such as wood, rubber, or foam. They are placed on the warehouse floor, and the steel coils are then stacked directly on top of them. Coil pads help to distribute the weight of the coils evenly and protect them from damage caused by contact with the floor. 5. Slit coil storage: Slit coils, which are narrower and lighter than full-size coils, can be stored using specialized storage systems. These systems often consist of racks or shelves equipped with dividers or separators to keep the coils organized and prevent them from unraveling. It is important to note that regardless of the storage method used, safety precautions should be followed when handling and storing steel coils in warehouses. This includes ensuring proper weight distribution, using appropriate lifting equipment, and adhering to industry-specific guidelines and regulations.

- Q:How are steel coils inspected for weldability?

- Steel coils are inspected for weldability using various methods, such as visual examination, non-destructive testing (NDT) techniques like ultrasonic testing or magnetic particle inspection, and chemical analysis. These inspections help identify any surface defects, internal discontinuities, or impurities that may affect the weldability of the steel coils.

- Q:How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide strength, durability, and energy absorption capabilities. These coils are typically formed into various shapes and sizes to create components that reinforce the vehicle's body, such as side impact beams or front and rear crumple zones. The steel coils absorb and distribute the impact energy during a crash, helping to protect the occupants by minimizing the force transferred to the passenger compartment.

- Q:Is infi steel as good as busse knives make it sound. If so why don't any other brands use it. Also are there any tactical folders that use infi steel. If infi isn't as good as it's cracked up to be then what is the best alternative.

- Infi Steel Knives

- Q:What are the different types of steel coil storage containers?

- There are several types of steel coil storage containers, including coil racks, coil cradles, coil saddles, coil cassettes, coil pallets, and coil cones. These containers are designed to safely store and transport steel coils, providing support and stability to prevent damage or shifting during handling and storage.

- Q:How are steel coils inspected for quality assurance?

- Steel coils are inspected for quality assurance through a combination of visual inspections, measurements, and non-destructive testing techniques. These inspections typically involve checking for surface defects, such as cracks, scratches, or corrosion, as well as ensuring the dimensions and weight of the coils meet the required specifications. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, are also used to detect any internal defects that may not be visible to the naked eye. Overall, these comprehensive inspections help ensure that steel coils meet the desired quality standards.

- Q:How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are not typically used directly in the manufacturing of electrical wiring. However, steel coils can be used in the production of wire drawing machines, which are used to stretch and shape the copper or aluminum wire used in electrical wiring.

- Q:aLSO, DOES STEEL C45 REFER TO THE CARBON IN IT?ALSO, WHAT IS AIRCRAFT GRADE PLYWOOD AND WHERE DOES ONE GET IT

- chromium nickle steel aka stainless steel exact amount of chrome and nickle will determine type/grade numbers Check the google for steel type/grade Never head of aircraft grade, however,, there is marine grade - normally baltic birch with waterproof glue and no defects i.e. knots, etc. Very strong (also quite expensive) but worth it for the correct applications

- Q:What are the common coil storage conditions?

- The common coil storage conditions include keeping the coils in a dry and well-ventilated area, away from direct sunlight and extreme temperatures. It is also important to store the coils in an upright position, on pallets or racks, to prevent damage and ensure easy access for handling and transportation.

- Q:What are the different grades of steel coils?

- There are several different grades of steel coils, including low carbon steel, medium carbon steel, high carbon steel, stainless steel, and galvanized steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, corrosion resistance, and formability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ppgi/Hot Sale Building and Electrical Steel Coil/Corrugated Roofing Sheets/ Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords