Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

1. Introduction of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

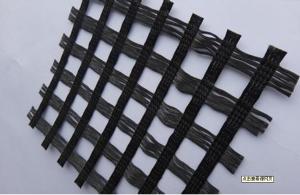

High strength polyester warpknitting geogrid adopts high strength, high modulus, and low shrinkage twisting industrial polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending among warp and weft direction.

Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction. Then it forms into mesh size product after coated with high quality watersoluble PVC which improves its strength, various technical standards and gives full play of its mechanical property.

2. Performance of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

High tensile strength

Low elongation

Excellent temperature resistant

Good anti-aging

Good alkali-resistance

3. Application of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

Strengthening soft roadbed of high-class roads and high speed railways, separating different subgrade soil material.

Using in reclamation engineering, dam, landslides and retaining wall.

Enhancing various roadbeds.

Strengthening soft roadbed of airport.

4. Packing and Delivery of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Q:meters. Material: tgsg. This section of subgrade for soft soil foundation (water) what is the purpose and principle of this treatment? Seeking answers experienced master change, or in the design the unit did. Thank you. Do a detailed description of indebted forever. My understanding is...Geogrid width of 3 meters, the berm soil subgrade body laying 1.4 meters, laying 1.6

- The main purpose of filling subgrade is to use geogrid, which is to prevent the longitudinal cracking and sliding. As for Geogrid, it can not directly stabilize the slope, but also rely on geotextile wrapped. As for the soaking embankment, in addition to the use of Geogrid and geotextile, but also consider the problem of slope protection (such as stone, concrete surface etc.).Geogrid is usually used to fill the embankment with high height, in order to play a role. Also, you said that the protection of the ramp laying 1.4 meters, the laying of the roadbed in the area of 1.6 meters, these are trivial, can only play a part of the role of little. See you use the material is plastic geogrid, this is the worst kind of material, the strength is very low. Small size, low strength, not as good as the use of woven bags stacked slope. I guess this is a low grade road

- Q:Do geogrids have any impact on groundwater?

- Geogrids themselves do not have a direct impact on groundwater. However, they can indirectly influence groundwater flow patterns by improving soil stability and preventing erosion. This, in turn, can potentially affect the recharge of groundwater.

- Q:What are the design guidelines for geogrid-reinforced retaining walls?

- The design guidelines for geogrid-reinforced retaining walls include factors such as the type and strength of the geogrid, the wall height, soil properties, and the required level of stability. The guidelines typically emphasize the need for proper engineering analysis, considering factors such as internal and external stability, soil-geogrid interaction, and construction considerations. It is important to follow industry standards and consult with a qualified engineer to ensure a safe and effective design for geogrid-reinforced retaining walls.

- Q:What are the physical properties of Geosynthetics

- Composite materials sometimes use a thin geomembrane, the thinnest up to 0.1mm; the thickness of the geogrid varies with the location, the thickness of the ribs from 0.5mm to dozens of millimeters.

- Q:Can geogrids be used in reinforcement of underground utility corridors?

- Yes, geogrids can be effectively used in the reinforcement of underground utility corridors. Geogrids provide structural support and stability to the soil surrounding the utility corridors, minimizing the risk of settlement and shifting. They improve the load-bearing capacity of the soil, preventing damage and potential collapse of the underground utility infrastructure. Additionally, geogrids can help distribute loads more evenly and reduce stress concentration, ensuring the long-term durability and performance of the utility corridors.

- Q:Can geogrids be used in stabilization of mine waste dumps?

- Yes, geogrids can be used in the stabilization of mine waste dumps. Geogrids are commonly used in civil engineering to reinforce and stabilize soil structures. By placing geogrids within the mine waste dump, it helps to prevent the material from shifting or sliding, providing stability and reducing the risk of slope failures. Additionally, geogrids also improve the overall strength and load-bearing capacity of the dump, promoting long-term stability and preventing erosion.

- Q:Are geogrids suitable for use in ground reinforcement for agricultural facilities?

- Yes, geogrids are suitable for use in ground reinforcement for agricultural facilities. Geogrids provide effective soil stabilization, erosion control, and load-bearing capabilities, making them ideal for reinforcing agricultural areas such as access roads, parking lots, and storage areas. They help distribute the load evenly, prevent soil compaction, and improve overall drainage, resulting in increased durability and longevity of the facilities.

- Q:Geogrid tgsg45-45 what does it mean

- Geogrid TGSG45-45, two-way plastic geogrid 45KN, I hope to help you.

- Q:What is the typical cost of a geogrid roll?

- The typical cost of a geogrid roll can vary depending on the size, material, and brand. However, on average, geogrid rolls can range in cost from $100 to $500.

- Q:Are geogrids suitable for use in slope stabilization for mining tailings dams?

- Yes, geogrids are suitable for use in slope stabilization for mining tailings dams. Geogrids provide reinforcement and stability to the slopes, preventing erosion and potential failure of the dam. They are designed to withstand high loads and are effective in controlling soil movement, making them an ideal solution for slope stabilization in mining tailings dams.

1. Manufacturer Overview |

|

|---|---|

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords