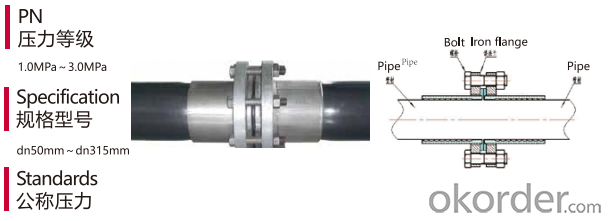

Pipe Crimpling Connection Crimping Steel Sleeve with Flange with Clamp

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

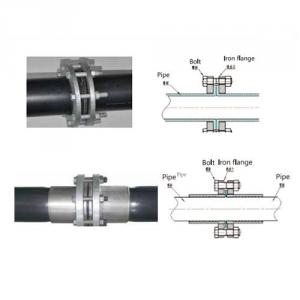

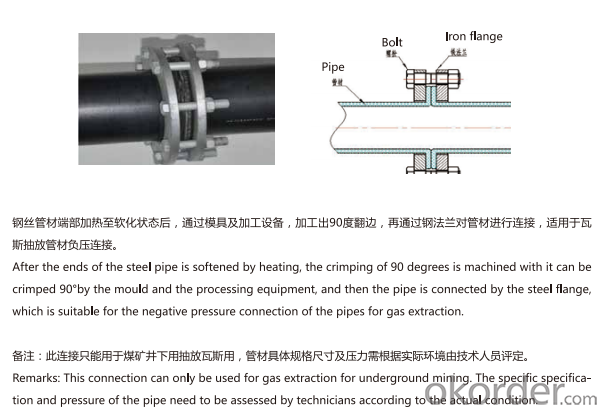

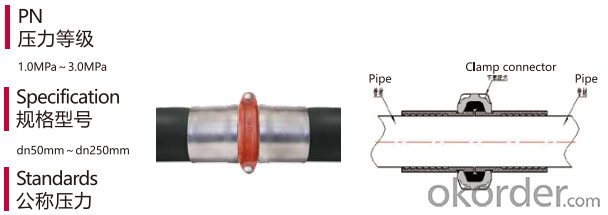

Pipe Crimpling Connection

Crimping Steel Sleeve with Flange

Crimping Steel Sleeve with Clamp

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:Are plastic pipe fittings resistant to ozone exposure?

- Yes, plastic pipe fittings are generally resistant to ozone exposure. Ozone exposure typically does not cause significant degradation or damage to plastic pipe fittings, making them a suitable choice for applications where ozone exposure is a concern.

- Q:Can plastic pipe fittings be used for industrial ventilation systems?

- Yes, plastic pipe fittings can be used for industrial ventilation systems. They are often preferred for their lightweight nature, corrosion resistance, and ease of installation. However, the specific type of plastic and its compatibility with the ventilation system's requirements should be considered to ensure the fittings can withstand the necessary temperature, pressure, and chemical conditions.

- Q:Are plastic pipe fittings resistant to seismic activity?

- Yes, plastic pipe fittings are generally resistant to seismic activity. They have the ability to flex and withstand ground movement during earthquakes, reducing the risk of damage or rupture. This makes plastic pipe fittings a reliable choice for seismic-prone areas.

- Q:Are plastic pipe fittings resistant to fungal growth?

- Yes, plastic pipe fittings are generally resistant to fungal growth due to their non-porous nature, which makes it difficult for fungi to thrive and grow on the surface. Additionally, most plastic pipe fittings are manufactured with antimicrobial properties that further inhibit the growth of fungi and other microorganisms.

- Q:Can plastic pipe fittings be used in fire hose reel systems?

- No, plastic pipe fittings should not be used in fire hose reel systems. These systems require durable and heat-resistant materials to ensure the safety and effectiveness of the firefighting equipment. Metal fittings, such as brass or stainless steel, are typically used in fire hose reel systems to withstand high pressure and extreme temperatures.

- Q:Can plastic pipe fittings be used for underground drainage systems?

- Yes, plastic pipe fittings can be used for underground drainage systems. They are commonly used due to their durability, resistance to corrosion, and ease of installation. However, it is important to select fittings that are specifically designed for underground use, as they need to withstand the pressure and environmental conditions associated with burial.

- Q:Are plastic pipe fittings resistant to high humidity environments?

- Yes, plastic pipe fittings are generally resistant to high humidity environments.

- Q:Are plastic pipe fittings resistant to corrosion from soil?

- Yes, plastic pipe fittings are generally resistant to corrosion from soil.

- Q:Are plastic pipe fittings resistant to thermal expansion?

- Yes, plastic pipe fittings are generally resistant to thermal expansion.

- Q:How do plastic pipe fittings compare to galvanized steel fittings?

- Plastic pipe fittings offer several advantages over galvanized steel fittings. Plastic fittings are generally more affordable, lightweight, and easier to install due to their simple and flexible design. They are also resistant to corrosion, which makes them suitable for use in various environments, including exposure to water. On the other hand, galvanized steel fittings are durable and can withstand higher temperatures and pressures, making them suitable for heavy-duty applications. However, they can be more expensive, heavier, and require specialized tools for installation. Ultimately, the choice between plastic and galvanized steel fittings depends on the specific needs and requirements of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pipe Crimpling Connection Crimping Steel Sleeve with Flange with Clamp

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords