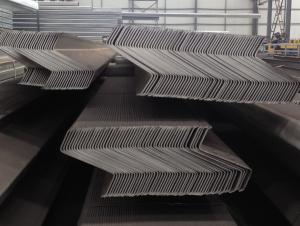

Photovoltaic Solar Hot Dip Galvanized C Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Photovoltaic Solar Hot Dip Galvanized C Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Photovoltaic Solar Hot Dip Galvanized C Steel are ideal for structural applications and are widely used in construction, automobile manufacturing, solar power, mechanical manufacture, power transmission tower bridge, ships, military aviation, railway construction, computer room equipment container, mineral bracket, etc

Product Advantages:

OKorder's Photovoltaic Solar Hot Dip Galvanized C Steel are very accord with roofing purline, metope purlin, the mechanical characteristics, make the mechanical performance of steel use light points. A variety of accessories can be connected into different combinations, appearance beautiful, use steel purlin, can reduce the roof weight, decrease engineering steel, therefore is called economic efficient steel, is instead of Angle steel, channel steel, steel pipes and other new building materials of the traditional steel purlin.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: cold bending

Grade: Q195 Q215 Q235 Q235B Q345B

Certificates: ISO, SGS, BV, CIQ

Rolling width of 60-400 mm,

Thickness 1.5-4.5 mm

Length: 6m – 12m, as per customer request

Standard: ISO9001:2000

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 30-45days.

Images:

- Q:Can solar mounting systems be installed on sloped terrain?

- Yes, solar mounting systems can be installed on sloped terrain. There are various mounting solutions available that can adapt to different slopes and angles, ensuring optimal positioning for solar panels. These mounting systems are designed to provide stability and secure installation even on uneven or sloped surfaces.

- Q:Are there any specific requirements for flashing when using a solar mounting system on a sloped roof?

- Yes, there are specific requirements for flashing when using a solar mounting system on a sloped roof. Flashing is essential to ensure a watertight seal around the penetration points where the solar panels and mounting system are attached to the roof. It prevents water from seeping into the roof and causing leaks. The flashing should be made of durable material, such as metal or rubber, and properly installed by a qualified professional to ensure the integrity of the roof and the solar system.

- Q:Can a solar mounting system be used with different types of solar panels?

- Yes, a solar mounting system can be used with different types of solar panels. Solar mounting systems are designed to be versatile and adjustable, allowing them to accommodate various sizes and shapes of solar panels. This flexibility enables the use of different types of solar panels, such as monocrystalline, polycrystalline, or thin-film, with the same mounting system.

- Q:Can a solar mounting system be adjusted to optimize sunlight exposure?

- Yes, a solar mounting system can be adjusted to optimize sunlight exposure. The angle and orientation of the solar panels can be modified to ensure they receive maximum sunlight throughout the day, enhancing the overall efficiency and output of the system. Additionally, some mounting systems incorporate tracking technology that allows the panels to follow the path of the sun, further optimizing their exposure.

- Q:Can a solar mounting system be used in areas with limited access to solar research facilities?

- Yes, a solar mounting system can be used in areas with limited access to solar research facilities. Solar mounting systems are primarily designed to securely install solar panels and provide structural support, regardless of the location. While access to solar research facilities may provide additional resources for testing and optimization, the functionality and installation of a solar mounting system can still be achieved without direct access to such facilities.

- Q:What is the expected maintenance cost for a solar mounting system?

- The expected maintenance cost for a solar mounting system can vary depending on various factors such as the type of system, quality of components, installation practices, and local environmental conditions. However, in general, solar mounting systems are designed to be low-maintenance and have minimal ongoing costs. Routine maintenance tasks may include inspecting and cleaning the panels, checking for loose connections or damaged components, and ensuring proper alignment of the system. These tasks can typically be carried out by the system owner or a professional solar installer. Overall, the expected maintenance cost for a solar mounting system is relatively low compared to other renewable energy systems.

- Q:Can a solar mounting system be used with solar concentrators?

- Yes, a solar mounting system can be used with solar concentrators. Solar concentrators are designed to focus sunlight onto a smaller area, increasing the intensity of the light. These concentrators can be mounted on a solar mounting system, allowing for optimal positioning and tracking of the concentrators to maximize energy output.

- Q:Can a solar mounting system be used in areas with limited access to sunlight?

- No, a solar mounting system is not suitable for areas with limited access to sunlight as it requires ample sunlight to generate electricity.

- Q:Can a solar mounting system be installed on a rooftop with a concrete tile roof?

- Yes, a solar mounting system can be installed on a rooftop with a concrete tile roof. The mounting system can be designed and adapted to securely anchor the solar panels to the concrete tiles, ensuring a stable and effective installation.

- Q:Are there any maintenance requirements for solar mounting systems?

- Yes, solar mounting systems require regular maintenance to ensure their optimal performance and longevity. This typically involves inspecting the system for any damage or loose components, cleaning the panels and racking to remove dirt and debris, and checking the system's alignment and stability. Additionally, it is important to monitor the system's electrical connections and wiring to identify any potential issues. Regular maintenance helps prevent efficiency losses and ensures the system operates effectively over its lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Photovoltaic Solar Hot Dip Galvanized C Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords