Perfils of Aluminum in Hot Sale 6063 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable.

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5-6 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

Products are exported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam, Nigeria etc, over 100 countries and regions all over the world.

1. Application of Perfils of Aluminum in Hot Sale 6063 6061

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

2. Feature of Perfils of Aluminum in Hot Sale 6063 6061

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

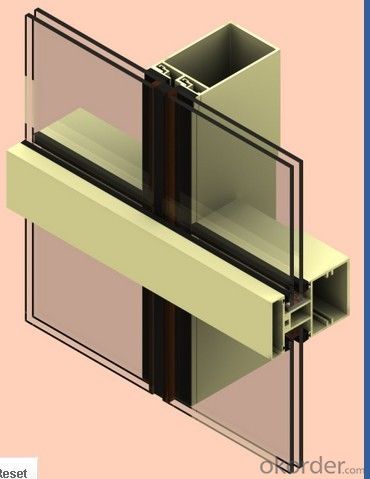

4. Image of Perfils of Aluminum in Hot Sale 6063 6061

5. Package and shipping of Perfils of Aluminum in Hot Sale 6063 6061

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

6. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:The latest list of aluminum China

- Lear aluminum is also good Oh, A Well-Known Trademark in China, China energy-saving innovation enterprise ten, Hebei enterprises in Handan

- Q:Are aluminum profiles suitable for balcony railings?

- Indeed, balcony railings can be effectively made using aluminum profiles. Aluminum is a favored material for balcony railings because it possesses qualities such as resilience, robustness, and minimal upkeep requirements. Its resistance to rust and corrosion makes it exceedingly appropriate for outdoor applications. Moreover, aluminum profiles can be effortlessly tailored and molded to match any desired design or architectural style. Although lightweight, they offer ample strength to ensure necessary support and safety for balcony railings. Additionally, aluminum railings are obtainable in a plethora of finishes and colors, providing limitless possibilities for design. On the whole, aluminum profiles are a dependable and fashionable choice for balcony railings.

- Q:Can someone give me a direction? Thank you

- Guangdong now has a lot of aluminum factory, and the price is very low

- Q:What are the different grades of aluminum used in profiles?

- The different grades of aluminum commonly used in profiles include 6061, 6063, and 6082. These grades vary in terms of their mechanical properties, corrosion resistance, and suitability for different applications.

- Q:Can aluminum profiles be used for electrical busbars?

- Yes, aluminum profiles can be used for electrical busbars. Aluminum offers excellent electrical conductivity, and its lightweight nature makes it a cost-effective choice for busbar applications. Additionally, aluminum profiles can be easily shaped and customized to meet specific requirements, making them suitable for various electrical systems.

- Q:Are aluminum profiles suitable for indoor applications with high humidity?

- Yes, aluminum profiles are suitable for indoor applications with high humidity. Aluminum is a non-corrosive material and is highly resistant to moisture, making it an ideal choice for environments with high humidity. It does not rust or deteriorate when exposed to moisture, ensuring its durability and longevity. Additionally, aluminum profiles can be coated with protective finishes such as anodizing or powder coating, further enhancing their resistance to humidity and preventing any potential damage. Therefore, aluminum profiles are a reliable and suitable option for indoor applications in high humidity environments.

- Q:What are the differences between the 6005 and 6003 aluminum profiles?Yangmingxg3

- 6003 of the magnesium content is higher than 6005, and the strengthening of magnesium to aluminum is remarkable. With the addition of 1% mg, the tensile strength increases by about 34MPa.

- Q:What are the different machining options for aluminum profiles?

- For aluminum profiles, there are various machining options to choose from, depending on specific requirements and desired outcomes. Some commonly used machining options for aluminum profiles include: 1. Milling: By utilizing rotating cutting tools, material can be removed from the aluminum profile, resulting in intricate shapes and features. This versatile option is suitable for both roughing and finishing tasks. 2. Drilling: Holes can be created in aluminum profiles through drilling. The precision and accuracy required determine whether a conventional drill or a CNC machine is used. 3. Tapping: To enable secure fastening, internal threads can be created in aluminum profiles through tapping. This is commonly used with screws or bolts. 4. Turning: By rotating the aluminum profile and applying a cutting tool, cylindrical shapes or features can be created through turning. This method is often employed for precise round components like shafts or pins. 5. Sawing: Aluminum profiles can be cut to specific lengths or straight cuts can be made using a saw blade. This process is known as sawing. 6. Bending: To achieve the desired form, force is applied to reshape the aluminum profile through bending. Various methods, such as press brakes or roll forming machines, can be utilized for this purpose. 7. Grinding: For a smooth, polished finish or to remove imperfections, grinding involves using abrasive particles to eliminate small amounts of material from the surface of the aluminum profile. 8. Welding: Joining aluminum profiles is commonly done through welding. This process involves melting and fusing the aluminum profiles together using heat and pressure, resulting in a strong and durable bond. These examples highlight the range of machining options available for aluminum profiles. The choice of machining method depends on factors such as the desired shape, size, finish, and specific application requirements of the profile.

- Q:What are the top 20 Chinese architectural aluminum profiles?

- 14, Fujian public security Aluminum Co. Ltd.15, Zhejiang pillars of new material Limited by Share Ltd16, Lear aluminum industry Limited by Share Ltd17 、 Ming emperor Aluminum Industry Co., Ltd.18, Guangdong silver100 innovation Aluminum Co. Ltd.19 、 Qingyuan Asia Aluminum Co., Ltd.20 、 Guanghan Sichuan Sanxing Aluminium Industry Co., Ltd.

- Q:Are aluminum profiles suitable for automotive racks and carriers?

- Aluminum profiles, indeed, possess the appropriateness for automotive racks and carriers. Being both lightweight and robust, aluminum emerges as an optimal material for instances that prioritize weight reduction, such as automotive racks and carriers. The adaptability and flexibility of aluminum profiles enable their design and engineering to cater to specific requirements, facilitating customization. Besides, aluminum's resistance to corrosion guarantees the endurance and long-lasting nature of automotive racks and carriers, even in unfavorable weather conditions. Moreover, the notable strength-to-weight ratio of this material contributes to an enhanced fuel efficiency and reduced emissions. In summary, aluminum profiles furnish a dependable and efficient resolution for automotive racks and carriers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Perfils of Aluminum in Hot Sale 6063 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords