Office Furniture Commerical Desk/Table Solid Wood CMAX-BG062

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: | Office Furniture | Specific Use: | Office desk | Style: | Commerical Desk |

Material: | MDF/MFC,Melamine | Folded: | No | Color | All color are available |

Volume: | 0.18 m3 | customization: | Yes | Model | CMAX-BG062 |

MOQ | 20 sets | Warranty | 2 years | General Use: | Commercial Furniture,office desk,office furniture,for executives/directors/presidents |

We specialized in office desk and office seating .

Our factory has been engaged in office furnitur e for more than 10 years.

Our factory is wellknown in the high quality and competitive price of our products.

Therefore, we completed in specifications and win warm praise from customers.

In addition, the design of our products is deft, modern and beautiful.

There are many types and colors for your selection.

Our goods are easy and simple to handle and durable in use.

Whether you need 1 office chair or big modular furniture, we offer the service, experience and attention you deserve -no matter how big or small the job is.

Your satisfaction is our goal, that's why we only supply furniture from top brands!

From workstations to cubicles, we have them all.

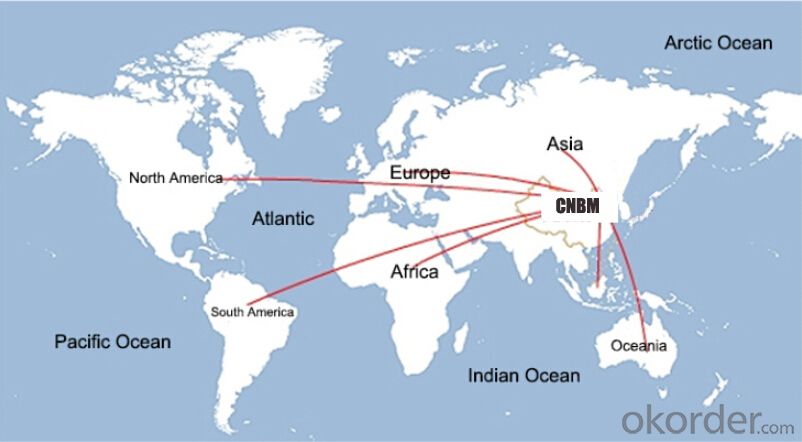

CNBM have a team of friendly and knowledgeable office Furniture and industrial furniture specialists with a specialists division who cater to our clientele who are looking for complete Office fitouts. At ROF we supply you more then just the chair or desks for your new working space, we create engaging and fresh office fitouts using our extensive range of Australia's best designs and qualities of office Furniture and industrial furniture.

Welcome any questions!

1. Features

1) Material: PU, PVC and fabric available

2) Height is adjustable

3) Rotary max. to 360

4) Slide freely with wheels

5) Designs and Patterns available upon requests

6) Different colors are available

7) Elegant design, excellent workmanship

8) Height of the seat and backrest are suitable

9) The pad thickness of the seat and backrest are suitable

2. Quality Control

1) Every product quality will be checked & cleaned before packing

2) We will try our best to help clients when problems occurred

3) Every step of production is carefully inspected by our professional QC clerk to ensure the quality of our products

CMAX-BG059

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG062

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG057

1800*1900*760

2000*2000*760

FAQ

Why choose us?

1, Advantage: Directly manufacturing factory with competitive price and quality control, we check all material when we start to bulk productions.

2, Professional advice to help you purchase the products you wanted/

3, Professional export service team servers in the deal.

4, Customization service is available, OEM business is appreciated.

5, We will inspect and test all products material carefully to ensure no damage and lost.

6, The success of our cooperation can be guaranteed for our company is a credible and honest partner.

How about the quality ?

1.Our normal material of MDF and MFC is with E1 standard. All oil paint we use is enviropaints. All kinds of Certification is available.Besides all the material could be customized.

How about the payment term?

1.Usually 30%T/T in Advace, the balance before shippment. L/C at sight could also be accept.

Other payment term could be discussed with specific orders.

- Q:What is the difference between laminated lumber (LVL) and plywood (plywood)?

- Plywood PLYWOOD, usually refers to the adjacent layer of wood fiber in the way of crossing, in order to tension is even.

- Q:Building engineering wood plywood can turn over several times?

- Turnover four or five times, no more problems, pay attention to brushing, release oil protection, sporadic damaged replacement.

- Q:What's the difference between a plywood press and a panel press?

- Use: laminator series machines are suitable for neutral or small man-made board furniture factory two processing factory (professional veneer), used for hot pressing adhesive plates, partition, building furniture doors and in various wood-based panels: such as plywood, blockboard, particleboard, MDF surface pressing various decorative materials, decorative paper, decorative melamine cloth, fireproof board, metal foil, artificial and natural veneer, natural wood mosaic; single version can not be used for drying leveling, leveling, setting the wood color decoration.According to the above content, you can compare.

- Q:Plywood with natural red oak bark at the end of what is the reason?

- Hello friend。 There are two possibilities. The first wood veneer is too thin. Second red like wood, rough wood a little.

- Q:How do you make the plywood process?

- Single plate - Section - log truncation wooden centering and rotary cutting veneer drying - processing - glue - cooling - Hot - embryo group and truncated - sanding test grading

- Q:Excuse me: is there a rubber board in the building material market that can replace glass instead of glass?

- PC endurance board (also known as polycarbonate solid plate, PC bulletproof glass, PC solid plate) is made of high-performance engineering plastic - Polycarbonate (PC) resin.

- Q:Plywood office furniture?

- What you said is too general! Office furniture materials are many, there are particleboard, MDF, solid wood composite, solid wood board.

- Q:What's the difference between plywood and glue E0E1?

- Depending on the composition of the gum, the glue used for building plywood is as follows:Urea formaldehyde adhesive: moisture-proof glue / for interior decoration, furniture, not for outdoor use.Melamine glue: moisture resistant, and has a certain water resistance and climate resistance / can be used outdoors or indoors, but not often immersed in water.Phenolic glue: moisture proof, excellent water boiling resistance and climate resistance characteristics can be used for outdoor or indoor / outdoor, can withstand exposed to wind and rain.

- Q:What are the building plywood used for?

- The construction of plywood mainly in outdoor conditions, such as building exterior decoration and concrete template, in the decoration engineering is mainly used in the ceiling, wall panels, floor liner.

- Q:What are synthetic plates, multilayer plates, plywood?

- The composite board is a wood board, fir board or multilayer plywood, the latter is light, easy to move, waterproof, and better synthetic board. Sometimes flatness is a little bit worse.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG062

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords