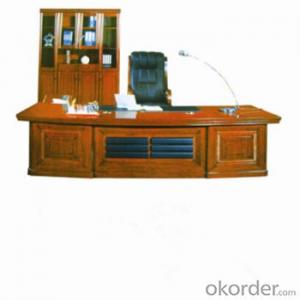

Office Boss Table with Excellent Surface Finishing

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Office Boss Table with Excellent Surface Finishing Description

We have 10 years experience in producing office furniture and provide all services for your import. This office boss table with Modern design is the newest design with optional colors. This boss table is anti-water, anti-dirty and anti-scratch. The boss table has a sturdy structure and excellent surface finishing.

Office Boss Table with Excellent Surface Finishing Characteristics

· Modern Design and optional colors

· High quality MDF, famous brand hardware

· Anti-water, anti-dirty and anti-scratch

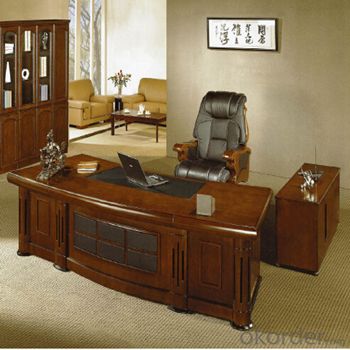

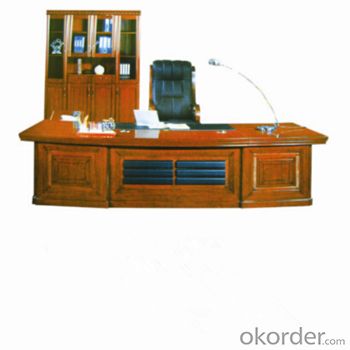

Office Boss Table with Excellent Surface Finishing Image

Office Boss Table with Excellent Surface Finishing Specification

Item | Content |

Name | Furniture |

Item Type | Office table |

Item Description | Office boss table |

Size | 3600*1100*760 |

Color | Reddish, Walnut, Brown, Black |

Material | MDF+Veneer, MDF+Paper |

Frame | Wood |

MOQ | 20 sets |

Production Capacity | 5000 sets per months |

Product Features | Anti-water, Anti-dirty |

FAQ

Do you accept OEM/ODM?

Products can be made according to your requirements. ODM/OEM is welcomed.

What is the warranty?

We offer 2-5 years warranty replacement against manufacturer defect.

What is your advantage?

We have strict quality control department to ensure all the goods to be right & correct delivery to customers.

All of our products are environmentally friendly meet the international standard.

- Q:What kind of glue do you want to make the plywood?

- Urea formaldehyde resin is the main adhesive for wood industry at home and abroad, because of its high strength, fast curing, good operation, low production cost, rich raw materials and easy access to a wide range of advantages and so on.

- Q:What is mirror exquisite rubber sheet?

- Mirror exquisite plastic sheet is a kind of finishing material which is coated with small aluminum sheet or plastic sheet coated with adhesive tape on the base of adhesive tape. OneIt's 400mm x 600mm, 600mm * 900mm, and each piece of it has a lens sheen and metallic texture, in the lightLight scattering can result in colorful scattering. Its colors are bronze, blue, blue, silver, green, cyan, gold and so on.According to the specifications of the aluminum sheet size can be divided into: small piece type, open type, open type.

- Q:What are the benefits of a plywood desk?

- The disadvantage is that it is too popular, and the more you use it, the more likely it is to devalue. Also, because of heavy and crisp plywood (mainly the glue itself heavy and brittle), its furniture screws, particularly by the connection of the regular activities of the loose leaf point tends to loose, so be sure to choose the regular manufacturers

- Q:Do you make furniture, carpentry or plywood? Which one is more expensive?

- In fact, the price is similar, because the wood board to paste panels and brush paint, these three processes finished, it is finished, so the three processes of artificial and materials together to calculate, but plywood a little expensive.

- Q:Please master, simple and easy to tell me what is: plywood, composite board, the kind of wood powder pressed into what the board? What are their characteristics, please?

- Wood powder pressing board is called density board. It has the characteristics of medium density and high density. It is not easy to deform. The disadvantage is that it is not water resistant and has poor nail holding ability

- Q:Which is good, Take Sakaki template?

- Strength: bamboo plywood with bamboo polishing sheet, and woven bamboo, short and long curtain curtain, in the template group embryo, with long and short curtain curtain Jingwei staggered, and then combined with high temperature and high pressure, high strength; wood template is pine bark and eucalyptus veneer layers of glue after the first cold pressing and hot pressing molding, two;

- Q:Desulfurization absorption tower anticorrosive lining glue, specifications have stipulated, rubber board need sampling?

- The surface treatment before the lining of rubber lining is an important link in the construction process of rubber lining. The steel shell surface treatment: artificial mechanical derusting, sandblasting derusting, chemical derusting, but for the surface treatment of rubber lining for vacuum equipment is practical and economic method or by sand blasting, choose suitable rubber lining equipment rust is the hard truth.

- Q:What is LVL plywood?

- Veneer lumber, referred to as LVL, is to wood as raw materials made of rotary cutting or slicing veneer, drying, glue, or most of the grain by grain blank sheet by hot pressing, and then glued together, it has the structural characteristics of solid lumber have high strength, toughness, stability well, the exact specifications, ratio of solid lumber in strength, toughness increased by 3 times. This product can be used in building formwork components, building beams, car panels, furniture, floors, room decoration, wooden keel and packing materials, and so on. It has a wide range of applications.

- Q:Decorate each floor, want to use bamboo plywood, just do not know to have poison?

- There is no poison floor, not eating Dongdong, there is no poison. Strictly speaking, is there any possibility of hurting people, or is it not environmental protection? Bamboo flooring is made of adhesive compression bonding products, adhesive is formaldehyde production out of harm to human body, not only the bamboo flooring, solid wood flooring has (paint containing formaldehyde), reinforcement (composite) floor also has formaldehyde release. Formaldehyde free bamboo wood flooring, solid wood flooring, laminate flooring is not, but also deceptive.

- Q:What kind of glue does plywood use now?

- 1, if the production of wood products in general indoor use, can use E1 (or E0) UF glue; if the waterproof performance is further to let the wood have more words, you can use the E1 class (or E0) melamine glue.2, if you want to make outdoor wood products, you can use E1 (or even E0) phenolic resin.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Office Boss Table with Excellent Surface Finishing

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords