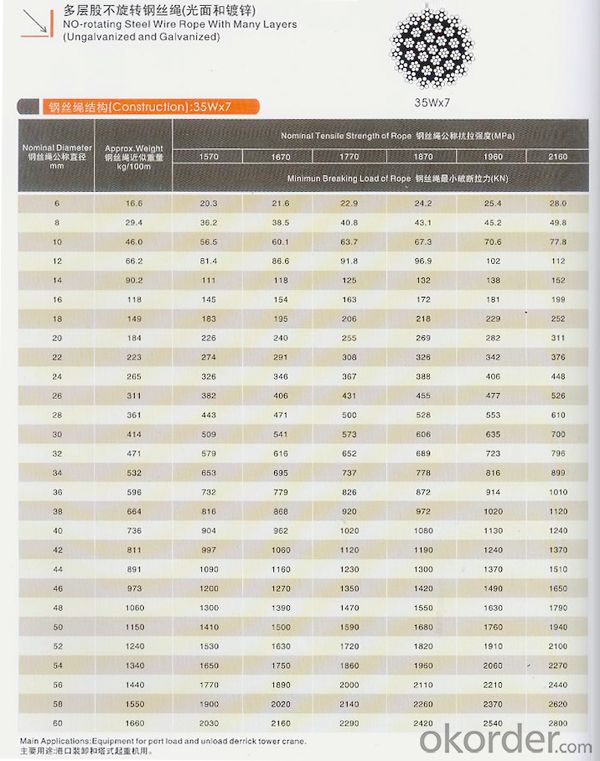

NON ROTATINGN ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What are the different types of steel coatings?

- There are several different types of steel coatings, including galvanized, stainless, epoxy, and powder coatings.

- Q:How is steel used in the production of medical devices and equipment?

- Steel is used in the production of medical devices and equipment due to its exceptional strength, durability, and corrosion resistance properties. It is commonly used to manufacture surgical instruments, implants, prosthetics, and various surgical and diagnostic equipment. The high strength of steel allows for precise and reliable performance, while its resistance to corrosion ensures longevity and sterility of medical tools in demanding healthcare environments.

- Q:How are steel sheets used in roofing and cladding systems?

- Steel sheets are commonly used in roofing and cladding systems due to their durability, strength, and resistance to weathering. These sheets are typically installed to create a protective barrier against external elements such as rain, wind, and sunlight. Steel sheets are lightweight, easy to install, and can be customized to fit various architectural designs. They provide structural support to buildings, ensuring longevity and stability. Additionally, steel sheets offer aesthetic appeal and can be coated or painted to enhance their appearance.

- Q:What are the different grades and specifications of steel products?

- There are various grades and specifications of steel products available in the market. These grades are determined based on the composition and characteristics of the steel. Some common grades include carbon steel, alloy steel, stainless steel, and tool steel. Each grade has its own specific properties and uses, such as carbon steel being suitable for general construction purposes, stainless steel being corrosion-resistant and used in food processing or medical equipment, and tool steel being used for cutting or shaping tools. Specifications of steel products can vary in terms of dimensions, strength, hardness, and other mechanical or chemical properties, depending on the intended application.

- Q:How is steel used in the production of industrial boilers and pressure vessels?

- Steel is used in the production of industrial boilers and pressure vessels due to its strength and durability. It provides the necessary structural support and can withstand high temperatures and pressures. Additionally, steel is resistant to corrosion, making it ideal for containing and heating various substances in industrial processes.

- Q:What are the different types of steel cladding and roofing available?

- There are several types of steel cladding and roofing options available, including corrugated steel panels, standing seam steel roofs, and metal shingles. Each type offers unique benefits in terms of durability, aesthetics, and ease of installation.

- Q:How is steel used in the production of playground equipment?

- Steel is used in the production of playground equipment due to its durability and strength. It is commonly used to construct the frames and supports of structures such as swings, slides, and climbing frames. Steel's robust nature ensures the equipment can withstand the weight and movement of children, making it a safe and reliable material for playgrounds.

- Q:What are the common types of steel products used in the automotive aftermarket industry?

- The common types of steel products used in the automotive aftermarket industry include steel sheets, steel bars, steel tubes, and steel wires. These products are used for various applications such as body panels, chassis components, exhaust systems, and suspension parts.

- Q:How are steel products used in the construction of theme-based science discovery centers?

- Steel products are commonly used in the construction of theme-based science discovery centers to provide structural support and stability. Steel beams and columns are used to create the framework of the building, ensuring it can withstand the weight of the structure and any potential loads. Additionally, steel is used for roofing, walls, and flooring, offering durability and resistance to fire and other hazards. Steel is also used to create intricate architectural designs and shapes, allowing for flexibility and creativity in the construction process. Overall, steel products play a vital role in ensuring the safety, functionality, and aesthetic appeal of theme-based science discovery centers.

- Q:What are the different types of steel valves and their applications?

- There are several types of steel valves commonly used in various industries. These include gate valves, globe valves, ball valves, butterfly valves, and check valves. Gate valves are primarily used for on/off applications and provide a tight seal when closed. They are commonly used in water treatment plants, oil and gas pipelines, and power generation systems. Globe valves have a spherical body and are suitable for regulating flow. They are frequently used in industries such as HVAC, steam systems, and chemical processing. Ball valves consist of a rotating ball with a hole that controls flow. They are versatile and widely used in applications where tight shut-off is required, such as oil and gas pipelines, chemical plants, and water treatment systems. Butterfly valves have a disc-shaped closure element that rotates to control flow. They are lightweight, cost-effective, and commonly used in applications involving large flow rates, such as HVAC systems, water supply networks, and wastewater treatment plants. Check valves, also known as non-return valves, allow flow in one direction only and prevent backflow. They are used in various applications, including pumps, compressors, and power plants. Each type of steel valve serves specific purposes based on their design and functionality. The choice of valve depends on factors such as the nature of the fluid, pressure and temperature requirements, and the specific application in industries ranging from oil and gas to water treatment and beyond.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

NON ROTATINGN ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords