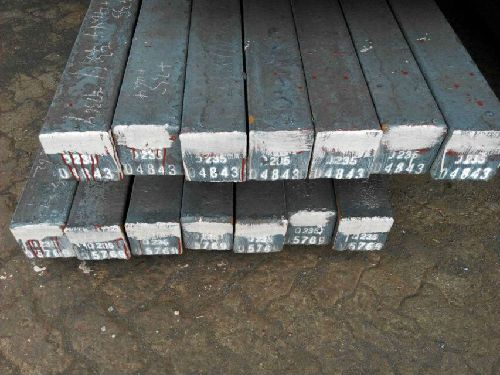

new producinh square steel;square bar, billet in sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

- Q:How do you use a steel square to lay out a stair stringer?

- To use a steel square to lay out a stair stringer, start by determining the desired rise and run of each step. Then, position the square on the stringer board, aligning the 7-inch mark on the tongue with the rise measurement and the 10-inch mark on the body with the run measurement. Mark the intersection point to indicate the vertical cut line for each step. Repeat this process for all the steps, ensuring consistent measurements and angles, and you'll have a properly laid out stair stringer using a steel square.

- Q:How do you use a steel square to measure and mark 219.375-degree angles?

- To measure and mark a 219.375-degree angle using a steel square, you would first align the long edge of the square with the reference line or edge. Then, locate the degree markings on the square's blade and find the 180-degree mark. From there, move along the blade towards the handle until you reach the 39.375-degree mark. Finally, align a straight edge or pencil with this mark and draw a line to mark the desired angle.

- Q:Can a steel square be used for marking out through dovetail joints?

- Yes, a steel square can be used for marking out through dovetail joints. A steel square is a versatile and accurate tool that can help ensure precise and square cuts when creating dovetail joints. It can be used to mark out the angles and dimensions of the dovetail joint, providing a guide for cutting and shaping the wood accurately. However, it is important to note that while a steel square can be a useful tool, it is also beneficial to have additional specialized tools, such as dovetail saws and chisels, to achieve the best results when creating dovetail joints.

- Q:Can a steel square be used for beam layout and construction?

- For beam layout and construction purposes, a steel square proves to be quite useful. Known by various names such as framing square or carpenter's square, this versatile tool is commonly employed in the fields of carpentry and construction. It comprises of a lengthy, straight edge and a comparatively shorter, perpendicular edge that creates a perfect right angle. When it comes to beam layout and construction, a steel square enables marking and measuring of angles and lengths, ensuring precise placement of beams. It assists in determining the appropriate cutting angles for beams and guarantees proper alignment and levelness during the construction process. Furthermore, a steel square serves the purpose of checking for squareness, ensuring that the corners of the beams are at accurate 90-degree angles. This aspect holds great significance in terms of structural integrity and stability. In conclusion, a steel square offers immense value for beam layout and construction due to its ability to deliver accuracy, versatility, and user-friendliness.

- Q:How do you use a steel square to ensure the correct angle for a dowel joint?

- Achieving the correct angle for a dowel joint can be easily accomplished by employing a steel square. Simply adhere to the following guidelines: 1. Commence by measuring and indicating the position where the dowel joint will be formed on both wooden pieces. It is imperative that the marks align perfectly to achieve a flush joint. 2. Place the steel square against the wooden edge, ensuring that one arm of the square rests against the wooden face. 3. Align the other arm of the square with the desired angle for the dowel joint. For instance, if a 90-degree angle is desired, ensure that the arm of the square is positioned perpendicularly to the wooden edge. 4. Once the square is suitably aligned, employ a pencil or marking knife to trace a line along the square's edge. This line will serve as an indicator for the correct angle of the dowel joint. 5. Repeat this process on the other wooden piece, ensuring that the angle lines align accurately when the two pieces are joined together. 6. At this stage, you can proceed to drill the dowel holes along the marked lines on each wooden piece. The holes should be drilled perpendicular to the wooden surface, utilizing the marked lines as a guide. 7. Finally, apply glue to the dowels and insert them into the holes, connecting the two wooden pieces. Secure the joint firmly with a clamp and allow the glue to dry according to the instructions provided by the manufacturer. By utilizing a steel square to precisely mark the correct angle for the dowel joint, you can guarantee a sturdy and accurate connection between the two wooden pieces.

- Q:Are steel squares resistant to rust and corrosion?

- Yes, steel squares are generally resistant to rust and corrosion. Steel squares are commonly made from stainless steel, which contains a high percentage of chromium. Chromium is a key element that provides stainless steel with its corrosion-resistant properties. It forms a protective layer on the surface of the steel, known as a passive film, which prevents oxygen from reaching the underlying metal and thus inhibits the formation of rust. However, it is important to note that the level of resistance to rust and corrosion may vary depending on the quality of the steel used. Higher-quality stainless steel squares will have a higher resistance to rust and corrosion compared to lower-quality steel squares. Additionally, the maintenance and care given to the steel squares can also affect their resistance. Regular cleaning and proper storage can help prolong their lifespan and maintain their resistance to rust and corrosion.

- Q:Can a steel square be used for chair rail installation?

- Yes, a steel square can be used for chair rail installation.

- Q:Can a steel square be used for marking out lap joints?

- Yes, a steel square can be used for marking out lap joints.

- Q:How does a steel square assist in checking the alignment of power tools?

- A steel square assists in checking the alignment of power tools by providing a straight and accurate reference edge or surface. It can be used to ensure that the tool's blade or fence is perfectly perpendicular or parallel to the reference edge, allowing for precise and accurate cuts or measurements.

- Q:What are the alternative tools for a steel square?

- There are several alternative tools for a steel square, depending on the specific task or measurement needed. Some of the most commonly used alternatives include: 1. Combination Square: This versatile tool combines a ruler and a square in one, allowing for precise measurements and angle markings. It is great for layout work, marking 90-degree angles, and measuring and transferring angles. 2. Try Square: Similar to a steel square, a try square is a simple tool used mainly for checking the accuracy of right angles. It consists of a metal blade and a wooden or plastic handle, making it lightweight and easy to handle. 3. Bevel Gauge: A bevel gauge is primarily used for measuring and transferring angles. It consists of a handle with a sliding metal blade that can be locked at any desired angle. This tool is particularly useful for woodworking and carpentry projects. 4. Speed Square (Rafter Square): Although commonly used in roofing applications, a speed square can also be used as a versatile measuring and marking tool. It features a triangular shape with different measurement scales, including degrees, inches, and centimeters. 5. Digital Angle Finder: For more advanced and precise angle measurements, a digital angle finder can be used. This tool uses digital technology to accurately measure angles and can provide instant digital readings, making it ideal for complex projects or when high precision is required. 6. Laser Level: While not a direct replacement for a steel square, a laser level can be used for straight-line measurements and leveling tasks. It projects a laser beam onto a surface, helping to ensure accurate alignments and layouts. Remember, the choice of alternative tools depends on the specific task and personal preference. It is always beneficial to have a variety of tools in your toolbox to tackle different projects effectively.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

new producinh square steel;square bar, billet in sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords