New Arrival H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

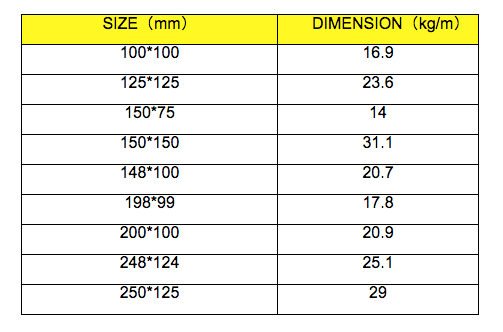

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:What are the design considerations for steel H-beams in multi-story buildings?

- Design considerations for steel H-beams in multi-story buildings include the material's strength and durability, load-carrying capacity, stability and resistance to lateral forces, fireproofing measures, and the need for proper connections and anchoring to ensure structural integrity. Additionally, factors such as cost-effectiveness, ease of fabrication, and constructability should also be taken into account during the design process.

- Q:Can steel H-beams be used for transmission towers?

- Indeed, transmission towers can utilize steel H-beams. In the construction sector, steel H-beams find wide application, serving as support for bridges, buildings, and transmission towers. Their robustness and resilience render them ideal for bearing substantial loads and enduring severe weather. Moreover, the ease of fabricating and assembling steel H-beams contributes to their cost-effectiveness in constructing transmission towers.

- Q:What are the considerations when designing for sustainable materials in Steel H-Beams?

- When it comes to designing Steel H-Beams with sustainable materials, there are several important factors to consider. These considerations revolve around the impact on the environment, the cost-effectiveness, the durability, and the overall sustainability of the materials used. 1. Environmental Impact: When incorporating sustainable materials, it is crucial to minimize the environmental impact throughout the lifecycle of the H-Beams. This can be achieved by responsibly sourcing materials from forests that are managed well or by utilizing recycled steel, which helps reduce deforestation and carbon emissions. 2. Energy Efficiency: Another crucial factor to consider is the energy efficiency of the manufacturing process. Designers should aim to reduce energy consumption and greenhouse gas emissions by selecting materials that require less energy to produce or by using energy-efficient manufacturing techniques. 3. Durability and Longevity: Sustainable materials should be durable and have a long lifespan. By designing H-Beams that are resistant to corrosion, wear, and tear, it reduces the need for frequent replacements, thereby minimizing waste and resource consumption. 4. Recyclability: The ability to recycle and reuse materials is essential in sustainable design. Steel H-Beams should be designed in a way that allows for easy disassembly and recycling at the end of their lifespan. This promotes a circular economy and reduces the demand for new raw materials. 5. Cost-effectiveness: While sustainability is a primary goal, it is also important to consider the cost-effectiveness of the materials used. Designers should strive to strike a balance between sustainability and affordability, ensuring that the use of sustainable materials does not compromise the overall project budget. 6. Compliance with Standards and Certifications: Designers should consider materials that meet recognized sustainability standards and certifications, such as LEED (Leadership in Energy and Environmental Design) or Cradle to Cradle. These certifications ensure that the materials have been responsibly sourced and manufactured. 7. Collaborative Approach: Finally, it is crucial to involve stakeholders, including architects, engineers, and manufacturers, in the decision-making process. By collaborating and sharing knowledge, the design team can identify innovative solutions that promote sustainability and address any challenges related to using sustainable materials in Steel H-Beams.

- Q:Can steel H-beams be used in outdoor applications?

- Yes, steel H-beams can be used in outdoor applications. Steel is known for its durability and resistance to weather elements, making it suitable for outdoor use. H-beams provide structural support and stability, making them commonly used in construction projects such as bridges, buildings, and outdoor structures.

- Q:300 * 150 * 6.5 * 9 H steel is used as steel beam, span 6 meters, spacing 2 meters, laying steel plate, 15 cm soil

- The concrete strength grade of the slab does not know, the reinforcement does not know, the bearing capacity of the board can afford, it can not be calculated.

- Q:Can steel H-beams be used in sports complexes and stadiums?

- Yes, steel H-beams can be used in sports complexes and stadiums. Steel H-beams are commonly utilized in these structures due to their high strength-to-weight ratio, durability, and ability to withstand heavy loads. They provide structural support for the roofs, grandstands, and other load-bearing elements in sports complexes and stadiums, ensuring the safety and stability of the entire structure.

- Q:Can steel H-beams be used in data center construction?

- Yes, steel H-beams can be used in data center construction. Steel H-beams are commonly used in construction projects due to their strength, durability, and versatility. They provide excellent load-bearing capabilities, making them suitable for supporting heavy equipment and structures in data centers. Additionally, steel H-beams offer a high degree of flexibility in design and can be easily customized to meet specific construction requirements. Their use ensures the stability and longevity of the data center, making them a popular choice in the construction industry.

- Q:How do steel H-beams contribute to daylighting in buildings?

- The inclusion of steel H-beams is crucial in enabling daylighting within buildings as they offer structural reinforcement while also facilitating the use of larger, more expansive windows. Daylighting involves utilizing natural light to brighten the interior spaces of a structure, thus diminishing the dependence on artificial lighting and fostering a more sustainable and pleasant environment. Steel H-beams possess a robust load-bearing capacity, making it feasible for them to span considerable distances and bear heavy loads, thereby allowing for the incorporation of larger window openings. These windows can be strategically positioned on exterior walls or even within the roof, granting the entry of abundant natural light into the building's interior. The utilization of steel H-beams in construction additionally confers architects with the ability to create buildings featuring open floor plans and soaring ceilings. This architectural freedom permits the incorporation of atriums, skylights, and other light wells that augment the penetration of daylight. Furthermore, steel H-beams exhibit remarkable durability and resistance to deformation, thereby ensuring the preservation of the structural integrity of the building while simultaneously maximizing the ingress of natural light. This characteristic is particularly crucial for regions prone to earthquakes or high winds. Apart from their structural advantages, steel H-beams are also highly versatile in terms of design and aesthetics. They can be seamlessly integrated into various architectural styles, thus allowing for the realization of innovative and visually appealing building designs that prioritize daylighting. Overall, the inclusion of steel H-beams significantly contributes to the achievement of daylighting within buildings by providing the essential strength and support for larger windows, facilitating the creation of imaginative architectural designs, and guaranteeing the longevity of the structure. By harnessing natural light, buildings can diminish energy consumption, enhance the well-being of occupants, and establish more sustainable and inviting spaces.

- Q:Are steel H-beams suitable for structures with complex geometries?

- Steel H-beams are commonly used in construction due to their high strength-to-weight ratio and versatility. However, when it comes to structures with complex geometries, their suitability may depend on various factors. Firstly, steel H-beams are typically produced in standard sizes and shapes, which may not be ideal for structures with irregular or intricate geometries. In such cases, custom fabrication or additional structural elements might be required to adapt the H-beams to the complex geometry, which can increase costs and complicate the construction process. Secondly, steel H-beams are most effective in structures that require long-span support or need to withstand heavy loads. Their inherent strength and rigidity make them suitable for structures like bridges, warehouses, and high-rise buildings. However, for structures with complex geometries that do not necessarily require long-span support or heavy load-bearing capacity, alternative construction materials or structural systems might be more appropriate. That being said, steel H-beams can still be used in structures with complex geometries, especially when combined with other structural components or advanced engineering techniques. By incorporating additional beams, trusses, or bracing, it is possible to distribute loads more evenly and enhance the structural integrity of the complex geometry. In conclusion, while steel H-beams are a versatile choice for many construction projects, their suitability for structures with complex geometries may depend on the specific requirements and design constraints. Consulting with structural engineers and architects is crucial to determine the best approach and select the most suitable materials for such projects.

- Q:Can steel H-beams be used for warehouse construction?

- Indeed, warehouse construction can make use of steel H-beams. These H-beams, also referred to as I-beams or W-beams, are extensively employed in the construction sector owing to their robustness and resilience. They are especially well-suited for warehouse construction as they offer structural reinforcement and are capable of bearing significant loads. With their ability to evenly distribute weight, steel H-beams are perfectly suited for bolstering the roof and walls of a warehouse, thereby ensuring its stability. Moreover, the ease with which steel H-beams can be fabricated and installed has made them highly favored within the construction industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New Arrival H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords