NEMA23 Step Motors with High Torque and Performance

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 100 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Step Motor:

1. High torque hybrid bipolar or unipolar

2. Step motor angle 0.9 or 1.8 degree

3. 178 oz.in, 268 oz.in and more

Step Motor:

Step angle 0.9 degree or 1.8 degree high torque hybrid bipolar or unipolar step motor

1. High torque hybrid bipolar or unipolar step motor

2. Step angle 0.9 or 1.8 degree

3. 178 oz.in, 268 oz.in and more

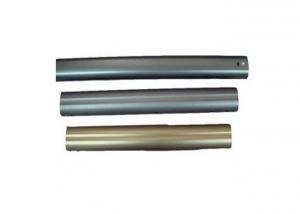

Size 57mm High Torque Hybrid Step Motor Specifications:

Series Model

| Step Angle (°) | Motor Length (mm) | Rated Current (A) | Phase Resistance (Ω) | Phase Inductance (mH) | Holding Torque (Kg.cm Min) | Rotor Inertia (g.cm²) | Lead Wire (NO.) | Motor Weight (g) |

UIM57-a | 1.8 | 51 | 1 | 5.8 | 17 | 9 | 190 | 4 | 560 |

UIM57-b | 1.8 | 56 | 2.8 | 0.9 | 2.5 | 12.6 | 300 | 4 | 700 |

UIM57-c | 1.8 | 76 | 2.8 | 1.13 | 3.6 | 18.9 | 480 | 4 | 1000 |

UIM57-d | 1.8 | 115 | 2.8 | 2.1 | 10 | 30 | 650 | 4 | 1800 |

- Q:The Z shaft screw is close to the motor and is equipped with 3 angular contact bearings. There are 2 bearings under it. Ask experts to teach me how to install, the top 3 how to arrange, the following 2 how to arrange, thank you!

- There are 3 bearings. Generally not 4, that is, 2. Angular contact bearings are marked on each side. Are generally installed back-to-back. The bearings are facing outwards.Some may pretend to be face-to-face. The two bearings, such as the made in China Harbin and the NSK, are put together. Back to a V word, like the NSK, the installation time is generally inverted V. The point in the direction of the screw.Extended introduction:Bearing (Bearing) is an important component of modern mechanical equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement and guarantee its rotation accuracy.According to the friction property of the moving element, the bearings can be divided into two kinds: rolling bearing and sliding bearing. Among them, the rolling bearing has been standardized and serialized, but compared with the sliding bearing, its radial dimensions, vibration and noise are relatively large, and the price is higher.Generally, the rolling bearings are composed of four parts: the outer ring, the inner race, the rolling body and the cage. According to the shape of the rolling element, the rolling bearings are divided into two major categories: ball bearings and roller bearings.

- Q:What material is used for the screw nut of machine tools?

- As the screw rod 1 to compressive strength and fatigue resistance enough 2 has certain plasticity and toughness, low coefficient of friction and good running in 3 has good thermal conductivity, thermal expansion coefficient and corrosion resistance of low alloy, sliding bearing

- Q:How can the accuracy of the CNC machine tools be compensated after a few years?

- Compensate by experience

- Q:CNC machine tool screw gap

- The gap is normal

- Q:How about the central screw in the CNC lathe? Or an ordinary side screw!

- Sen's advantage: cheap. Disadvantages: in addition to cheap. 6136 a little more than 5. Buy 36, buy 40, not much money. I don't know how high the power of the 36 spindle is, anyway, 40 is 5.5KW. Variable frequency spindle is more sensitive to power. Low speed, the output force is not enough, and sometimes will stop the spindle. Now that you choose big Sen, you value his merits. Well, I won't comment either. The design of the middle screw leads to the inconvenience of cutting, and no improvement has been found in the design process. Goods than three in order to find quality products, the boss, you may as well more Internet, check different machine tool factory products, learn more to earn more. I wanted to go on, but when I saw the eggs, I was really embarrassed to go on.

- Q:I'd like to make my own lathe screw. What material should I use?

- 45 steel rough car, and then quenched and tempered, and finally tune the thread

- Q:Is the grease of the machine tool screw rod good or weak?

- Thick point, not too thin, bearing high speed spin will be thrown out when the thin oil.

- Q:I would like to ask what method installed, do not know how many balls, loaded and loaded less, what is the situation, ah, urgent, thank you

- The first floor is right, but this way to operate, few people installed good, there are special tools for ball bearings, if the screw gap, you can replace the ball to repair. LZ I can send you a tool map if necessary. Your points are very attractive - -,

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai,China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | 7.14% North America 7.14% South America 7.14% Eastern Europe 7.14% Southeast Asia 7.14% Africa 7.14% Oceania 7.14% Mid East 7.14% Eastern Asia 7.14% Western Europe 7.14% Central America 7.14% Northern Europe 7.14% Southern Europe 7.14% South Asia 7.14% Domestic Market |

| Company Certifications | CE and RoHS |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

NEMA23 Step Motors with High Torque and Performance

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 100 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords