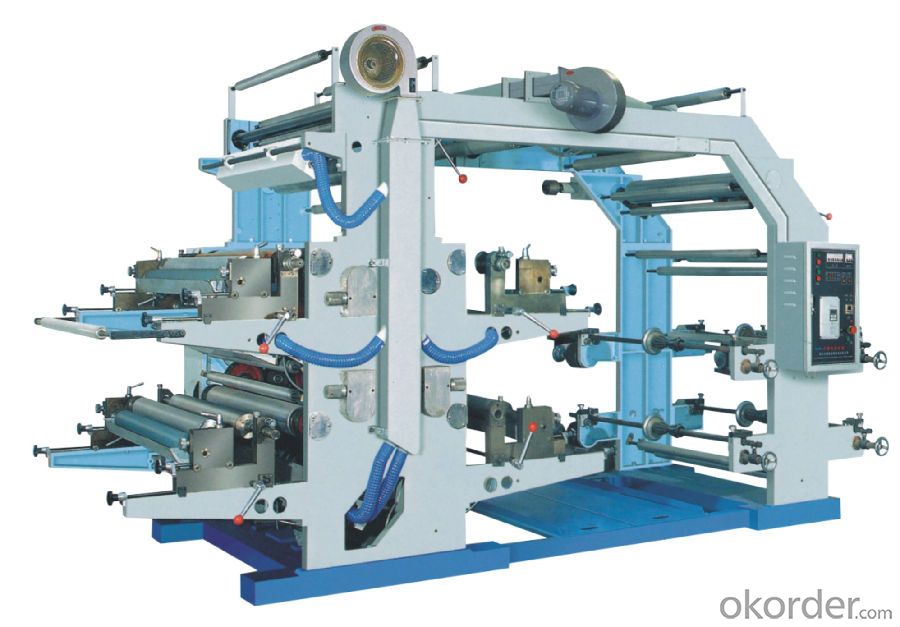

Multi Color Corrugated Carton Flexo Printing Machine With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

________________________________________

This machine is suitable for printing such packing materials as polyethylene,polypropylene plastic bag,cellophane and roll paper,etc.And it is a kind of ideal printing equipment for producing paper packing bag for food ,supermarket handbag and clothes bag,etc.

Station for 5-color flexo printing machine:

________________________________________

1.One mounting machine

2.One anilox roller for each group (lpi is optional, made in shanghai)

3.Three sets printing rollers (3*5=15)

4.Printing both sides at the same time (with turn bar)

5.With the lamination station

6.One unwinding tension controller (Mitsubishi Japan)

7.One rewinding tension controller

8.One rotary die cutting station

9. One rotary sheeting station

CHARACTERISTIC

1, Ceramic anilox cylinder are adopted for ink transferring.

2, The unwinding and rewinding units are designed with magnetic powder brakes and clutchs for tension control, and flexo machine equipped with Mitsubishi auto tension controller.

3, Each printing unit is adopted 360°printing plate-adjustment.

4, All printing units are equipped with a group of hot air dryer.(UV dryer is for option)

5, The machine has one die-cutting station, and it can make printing and die cutting finished in one process.

6, The ink rollers will be automatically separated from the printing roller, and it will keep rotating at a low speed, thus preventing ink from drying.

7, The main motor is equipped with an imported variable frequency stepless speed govermor.This guarantees the stable performance of flexo press.

8, The machine can finish material-feeding, printing, vanishing, drying, laminating, die-cutting and rewinding at one stroke. It is an ideal machine for printing trade invoice and top-grade adhesive label.

OPTION:

1, Web guiding system

2, UV dryer

3, Separate unwinder shelf (diameter up to 900mm)

4, Corona treater

5, Cold stamping unit

6, Video inspecting system

7, Safe cover for printing unit

Main technical parameter

________________________________________

Model | CMAX-320 | CMAX-450 |

Printing speed | 50m/min | 50m/min |

Printing color | 5colours | 5colours |

Max. width of paper | 320mm | 480mm |

Max .printing width | 310mm | 450mm |

Max. unwinder/rewinder diameter | 600mm | 600mm |

Printing length | 175-355mm | 175-355mm |

Thickness of flexo plate | 1.7mm or 1.14mm | 1.7mm or 1.14mm |

Precision of chromatography | ±0.1mm | ±0.1mm |

Dimensions | 2.1mX1.2m X2.6 m | 2.1mX1.35m X2.6 m |

Machine weight | About 2200kgs | About 2400kgs |

Product show

________________________________________

RFQ:

________________________________________

1, Q: How about the after service?

A: We have a strong team, special for after service. We can arrange engineers to do service for you.

2, Q: Are you factory or trading company?

A: We are a factory in this field nearly 20 years (Formally named Ruian Donghai Printing Machinery Co.,Ltd.).

3, Q: Where is your factory located? How can I visit there?

A:Our factory is located in Beijing City, China, You can fly to Beijing airport directly.

4, Q:How does your factory do regarding quality control?

A:Quality is priority. We always attach great importance to quality controlling from the beginning.

5, Q: why choose CNBM Machinery?

A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

- Q:What is the direction of the printing press?

- Large, multi-color, multi-functional, and automation, linkage, serial models and models, also growing.

- Q:What is flat pressure printing press?

- At the time of printing, the embossing plate is reciprocated around the spindle to complete the feeding and embossing.

- Q:What is a screen printing machine?

- Screen printing machine is the hole printing machine printing machine in the more representative of the printing equipment, its plate is made of silk and other materials woven from the criss-cross, latitude and longitude of the screen.

- Q:What is the printing machine?

- These mechanical devices have different properties and uses, so the mechanical form of them is not exactly the same.

- Q:What is gravure printing machine?

- Machine in the printed color, the first plate immersed in the ink tank rolling, the entire plate surface was painted with ink layer.

- Q:What is a lithographic printer?

- One of the monochrome offset press and web offset press is representative.

- Q:What is the historical development of presses?

- and the maximum printing speed of the sheet-fed offset press was 10,000 impressions per hour. A four-color printing press before the pre-adjustment preparation time is generally about 2 hours.

- Q:What is the basic classification of printing machinery?

- First, according to the layout type is divided into: letterpress printing press, lithographic printing press, gravure printing press, stencil printing press;

- Q:What is a letterpress printing machine?

- The When the machine is working, the platform is reciprocating, the printing speed is limited, so the output is not high; round pressure round letterpress printing machine, also known as rotary printing press, it install plate version of the plate and embossing institutions are circular drum.

- Q:What is the application of the press?

- Printing machine at the start, the motor current will be 5-6 times higher than the rated,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Multi Color Corrugated Carton Flexo Printing Machine With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords