Linear type bottle blowing machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This machine is the introduction of foreign advanced technology counterparts on the basis of the trend for domestic blowing equipment to high-speed, high-volume development, specially developed, developed. Mainly be used for pure water and mineral water PET bottle blowing. The machine has reasonable structure, small footprint, low power consumption, gas consumption, good stability, and many other advantages: and in line with national food hygiene standards in the domestic leading level, the device is ideal equipment for all types of domestic and medium-sized companies.

Main features of equipment

The whole operation with touch-screen operation, full Chinese display, production speed, shift production counting, fault type, etc. can be displayed on the screen. And automatic statistics failure time, fault type and other information, can achieve Man-machine dialogue;

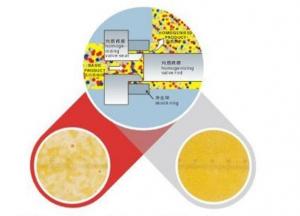

• secondary blowing system specially designed to ensure the stability of the bottle molding quality, appropriate technology to meet customer standards;

• using four infrared heater thermostat control, digital automatic voltage regulator thermostat system;

• You can set the appropriate temperature according to different preform is heated, and the other contains a variety of bottle-shaped blown required packages;

• Equipped with automatic processing machines and preform billet hoist;

ASG automatic linear type blowing machine Technical Parameters

Model | SY-20 | SY-40 | SY-60 | SY-80 |

Type | Automatic | Automatic | Automatic | Automatic |

Capacity | 2,000 pcs | 4,000 pcs | 6,000 pcs | 8,000 pcs |

PLC sys. | SIEMENS | SIEMENS | SIEMENS | SIEMENS |

Actuator sys. | MITSUBISHI | MITSUBISHI | MITSUBISHI | MITSUBISHI |

Operating system | Touch screen | Touch screen | Touch screen | Touch screen |

Power Sylinder | SMC | SMC | SMC | SMC |

Bottle size range | Up to 2.5L | Up to 2.5L | Up to 2.5L | Up to 2.5L |

Main motor | 40 kw | 60 kw | 60 kw | 80 kw |

Dimension(mm) | 2155×1750×2120 | 3280×1750×2200 | 5500×2200×2130 | 7280×3550×2200 |

Weight | 3.5 T | 5 T | 6.5 T | 10 T |

- Q:Drink equipment of the washing machine

- (1) the machine is cleaning a variety of plastic bottles of special equipment;

- Q:Filling machine installation precautions

- 4, with the handle shake the machine, check the machine is running in the correct direction (facing the motor spindle counterclockwise direction), the machine must be protected ground

- Q:What is the electronic water treatment device?

- High-frequency electronic water treatment device (device), also known as scale anti-scaling instrument,

- Q:Food sterilization with high-temperature sterilization pot or microwave sterilization equipment is good?

- Broth, cooked meat, noodles and other packaged food in the sterilization process, with high temperature sterilization pot or microwave sterilization equipment is good?

- Q:Today's human society on the development and utilization of water resources are divided into two categories

- The other is the use of water (hydroelectric power), the development of water transport,

- Q:What is the hospital water treatment equipment?

- · Raw water - raw water pressurized pump - Multi-media filter - Activated carbon filter - Water softener - Precision filter - Primary reverse osmosis equipment - Intermediate water tank - Middle water pump - Ion exchanger - Purified water tank - Pure water pump - UV sterilizer -

- Q:How to use sealing machine

- There are automatic aluminum foil sealing machine, do not know that you consult the sealing machine to do the program ah!

- Q:What is the purified water equipment?

- Purified water equipment is used to meet the needs of the industry to produce pure water equipment, used in medicine, chemical and chemical industry, the entire system of purified water equipment are also made of stainless steel combination, and before the water must be equipped with sterilization device

- Q:Sealing machine precautions

- 3, the use of single-phase three-wire power cord, in order to make the operator safe, be sure to use single-phase three-wire power outlet, the workplace ground must be dry to keep insulation.

- Q:Easy to control, easy to achieve automated production

- Compared with conventional sterilization, microwave equipment does not require boilers, piping systems, coal fields and transport vehicles, as long as the basic conditions of water and electricity can be, no special requirements on the plant, less investment, quick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Linear type bottle blowing machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords