Light Industry Use PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Industry Use PVC Conveyor Belt PU Conveyor Belt

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

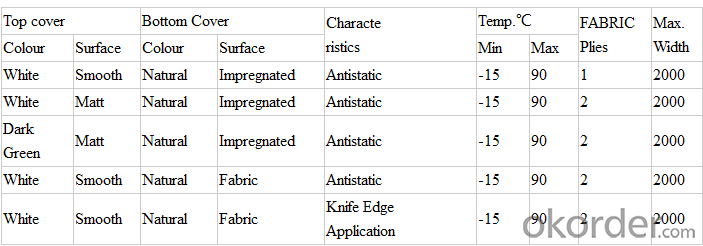

PVC/PU conveyor belt/FDA

1. material: PVC/PU

2. color: white,dark green,sky bule,etc

3. surface: smooth,matt

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Product Photos

For more informations,please contact us freely,thank you.

- Q:How many grades are there in the plastic block? How to divide?

- UL is a plastic material standard test piece by spontaneous combustion flame after the combustion time, combustion speed, falling particle state to set the plastic material fire resistance rating, according to the level of quality, followed by HB, V2, V1, V0, 5V, VTM-0, VTM-1 and thin material grade, VTM-2, and foam material grade HBF, HF-1, HF-2.

- Q:Can olive nets be used in combination with tree training methods?

- Yes, olive nets can be used in combination with tree training methods. Olive nets are commonly used to protect the olives from birds and other pests during the growing season. They can be easily integrated with various tree training methods such as open vase, central leader, or espalier systems. The nets can be installed over the trained tree structure to provide protection while still allowing sunlight and air circulation.

- Q:How does an olive net affect the overall fruit color in the olive grove?

- An olive net can have a significant impact on the overall fruit color in an olive grove. By providing shade and protection from direct sunlight, the net helps to maintain a more uniform color throughout the fruit. This can prevent excessive sunburn, which can lead to uneven ripening and discoloration. Additionally, the net reduces the exposure of olives to wind and dust, further enhancing their color development. Overall, the use of an olive net improves the fruit color and ensures a more visually appealing and marketable yield.

- Q:Can olive nets be used for mechanical harvesting?

- Yes, olive nets can be used for mechanical harvesting. Olive nets are commonly used in conjunction with mechanical harvesters to collect the olives that are shaken off the trees during the harvesting process. These nets help to gather the olives efficiently and prevent damage to the fruit.

- Q:Scope and characteristics of plastics No. 7

- Plastic No. 7 represents polycarbonate (PC), other plastic products. PC is a widely used material, especially for bottles and space cups, which is controversial because it contains bisphenol A. Experts point out that, in theory, as long as the process of making PC, bisphenol A percent into plastic structure, it means that the product is not bisphenol A, let alone release. However, if a small amount of bisphenol A is not converted into a plastic structure of PC, it may be released into the food or drink.

- Q:Do olive nets require any special storage conditions?

- Yes, olive nets should be stored in a cool, dry place away from direct sunlight to prevent damage and maintain their quality.

- Q:Are olive nets safe for beneficial insects?

- Yes, olive nets are generally safe for beneficial insects. These nets are designed to protect olive trees from pests while allowing beneficial insects, such as bees and ladybugs, to pass through. The fine mesh of the nets prevents larger insects and pests from reaching the olive trees, ensuring the safety and well-being of beneficial insects.

- Q:Do olive nets affect the color of the olives?

- Yes, olive nets can affect the color of the olives. The nets are primarily used to protect the olives from birds and other pests, but they can also create a microclimate that affects the ripening process. This can lead to variations in color, with olives under the nets sometimes appearing darker or lighter compared to those exposed to direct sunlight.

- Q:How much do olive nets typically cost?

- The cost of olive nets typically varies depending on factors such as the size, quality, and material of the net. On average, olive nets can range from $10 to $50 per net.

- Q:How do olive nets impact the overall texture of the olives?

- Olive nets have a minimal impact on the overall texture of the olives. The nets are primarily used to catch the olives as they fall from the trees during harvesting. This method helps prevent damage to the olives and maintains their natural texture.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Industry Use PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords