Light Duty Casting Iron Manhole Cover with High Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

product name: ductile iron manhole cover

1. material: cast iron, ductile iron, malleable iron

2. duty: EN124 A15 B125 C250 D400 E600 F900

3. color: black green gray and etc.

4. design: we can provide OEM service, according your design to do moulds, surface and logo.

5. application: expressway, sidewalk, park, garden, municipal pipeline, telecommunication, water and electrical power projects.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Features

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted.

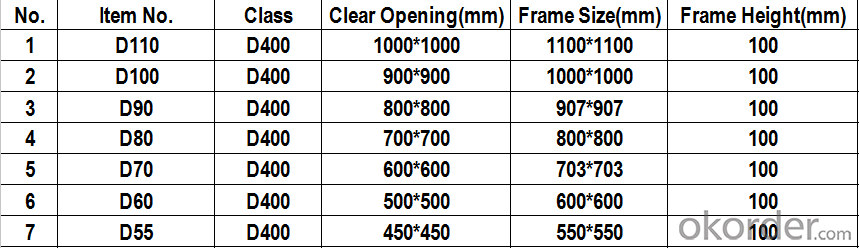

Specifications

Our company

Ductile Iron Manhole Cover and Grating

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group. CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

FAQ

Why imported Composite Manhole cover/Grating fromChina?

1. Very competitive price, it will save you third or even half cost;

2.Good quality, don't worry much about the quality, actually, most of the building materials you buy from Miami, Dubai ,Italy, South Africa or your local market are imported from China. So why not buy direct from China. The key point is to find a reliable supplier who is honest and professional to take care of the quality and delivery time.

3.China has full range of Manhole covers which Follow En124 for your market, like A15,B125,C250,D400.

- Q:Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q:ZGMn13 casting parts processing, with what knife head good?

- its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

- Q:What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q:What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q:Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q:Can the casting part be phosphating with the phosphating solution of the pickling board?

- Like stainless steel casting, duplex stainless steel casting is phosphating, ductile iron gray iron is not required

- Q:Which surface is coarser for cast iron or cast steel castings? Why?

- Roughness mainly depends on the surface roughness on the surface of the sand.

- Q:Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q:Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q:How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- Casting parts do not need to provide drawings of casting blank, the casting factory according to your drawings in the required surface will be sufficient allowance, and the rest of the size according to the mechanical design manual and the casting manual can be found.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Duty Casting Iron Manhole Cover with High Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products