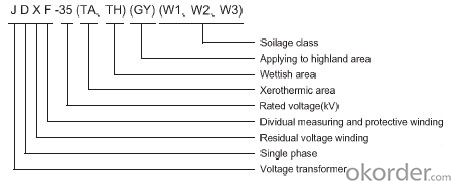

JDXF-35 TA,TH GY W1,W2,W3 Voltage Transformer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type description

Technical characteristic

1.It accords to the GB1207-1997<voltage transformer> ,IEC186 and IEC60044.

2.This product has the character of limited tightness.All the tightness compartment do not be put into ultraviolet radiation so that we solve the problem of chap of tightness rubber and aging,these product is more reliable and has longer life,we ensure that it can run 20 years without leakage.

3.The porcelain is equipped with irragateing flange.the surface of flange use hot zincification to enhance the wholly mechnism of product and has beautiful outlook.

4.This product is equiped with bellow and is tightnesds completely.

5.With higher accuracy to 0.2,we can reach the requirment of customer with seperatly measuring secondary winding and protection winding.

6.With epoxy secondary terminal board,the product is enhanced secondary insulation and tightness.

7.All the standard comparthent are plated Dakelo.We ensure that the product don't rust for 20 years.

8.The inner structure of this product has changed largly and we solve the problem of old 35KV PT with unreasoned inner structure for the unpassed dielectric loss,This product has low partial discharge and litter dielectric loss with advanced workcraft.

9.The excitaton density of this product is equal or less than 0.7T and has the ability of avoiding ferro-resonance.

Technical Data

| Type | JDXF-35 | |

| Rated voltage | Primary winding | 35/ |

| Measuring winding | 0.1/ | |

| Protection winding | 0.1/ | |

| Residual voltage winding | 0.1 | |

| Frequency | 50HZ | |

| secondary accuracy and reated output | Measuring winding | 80VA 0.2 class |

| Protection winding | 150VA 0.5class 250VA 3P class | |

| Residual voltage winding | 100VA 6P class | |

| Rated limit output | 2000 | |

| Rated insulation level | 4.05/95/200 | |

| Creepage distance | 810,1050,1250 | |

| Flash distance | 410-500 | |

| Total weight/Oil weight | 40/190 | |

| Pack size | 580×600×1300 | |

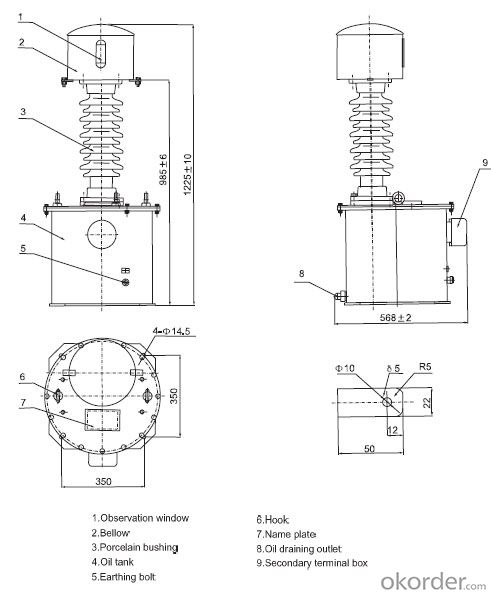

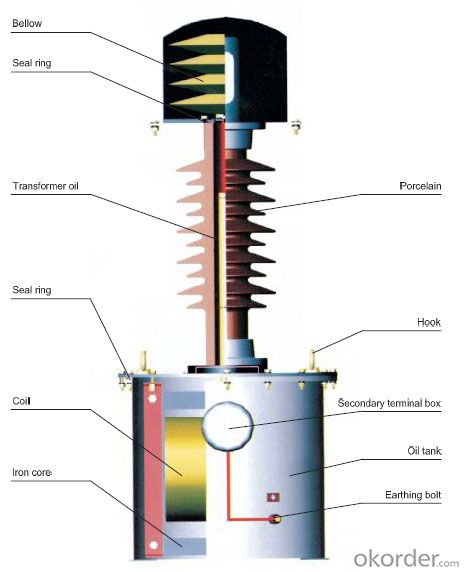

JDXF-35 Voltage Transformer Outline Drawing

Srructure drawing

- Q:How to use a multimeter to determine the quality of small transformers

- First with a multimeter resistance file RX1 or RX10 to test the transformer on both sides of the coil! Have to pass! Primary resistance large! Secondary resistance small! (Buck) And then test the first class! Can not pass! Basic determination is good! And then use the transformer at both ends of the primary coil to take the multimeter AC voltage 50-100 volts stalls! With a dry battery to touch the transformer secondary coil ends! At this point multimeter watch pin should have a strong swing! Induced current and mutual inductance voltage! This proves that the transformer all normal! No turn-to-turn short circuit!

- Q:I have a 120v-36v transformer hooked up to a bridge rectifier composed of 4x IN4004 diodes, 2 filter capacitors and a 100k resistor paralleling them as a bleeder resistor. The rectifier puts out the full 50v DC I expect it to, but at the same time the transformer faintly vibrates (you can only really tell if you touch it), and over time it gets quite hot. Why is this? I have checked over my connections quite a few times and I am 99.9% sure its all connected properly.

- Since you are getting the correct voltage from the transformer+rectifier+filter, the most likely reason the transformer is heating is that it is has been designed with the least amount of wire that can possibly do the job, and thus the resistive losses are fairly high in the primary winding (the winding connected to 120 V). If you will be drawing a lot of power from the supply, you should ensure adequate ventilation for the transformer for cooling. Most transformers have a strap that can be mounted to a metal case to help dissipate some of the waste heat. If the excess heat is a problem, you might consider upgrading to a higher wattage transformer. Be sure to check the output voltage under load - it won't be nearly as high as when there is no load connected. The vibration may be due to low quality lamination in the metal transformer core, or loose windings, or both. (The transformer core is made up of thin strips of iron that are insulated from each other, usually with a thin lacquer coating. Quality transformer cores will be very tightly laminated.) The vibration/noise is consistent with the apparent low quality of the transformer, but should not be a problem.

- Q:I have a 240 to 12 volt electronic transformer for each 50w halogen bulb. Trying to track down a fault, I tested the transformer with my multimeter - it showed 240v input but showed zero v output so I concluded that the transformer was faulty BUT when I plugged in a bulb it lit up normally. Can anyone explain ??

- Different kind of voltage. Did you switch your multimeter to read DC voltage? Most lighting ballasts are ac output (like fluorescent or metal halide). In the case of mr16 50w light bulbs typically power is 12v dc output from either an electronic or magnetic transformer. Magnetic is heavy iron with copper wound like a typical door bell transformer. Electronic is smaller and lighter using circuit boards to convert the voltage. In both cases it will be DC. Something else to consider is worn contacts where the bulb connects. And m16 bulbs don't last very long. Oil from your hands will shorten their lifespan even more. Also poor heat dissipation through the fixture. I've worked with a lot of the types of fixture you're speaking of. (usually 4 recessed cans but also pendants and track fixtures)

- Q:315KVA transformer high-voltage side need to use the specifications of the high-voltage cable

- To the formula high-voltage side rated current = 315 / (1.732 * 10) and then check Kazakhstan with the wire rated current know the choice

- Q:A liter of transformer oil how much jin

- (3) arc suppression effect: In the oil circuit breaker and transformer on-load regulator switch, the contact will produce an arc switch. As the transformer oil thermal conductivity is good, and in the arc under the action of high temperature can touch a lot of gas, resulting in greater pressure, thereby enhancing the dielectric arc performance, so that the arc quickly extinguished.

- Q:Rules for the operation of cooling devices for oil - cooled transformers

- A, cooler should take their own independent dual power supply, and can automatically switch, when the work of power failure, automatically put into standby power, and issued a sound signal; ?B, the transformer upper oil temperature reaches 55 ℃ or the current reaches 70% of the rated value, the auxiliary cooler automatically input;

- Q:I have an AC to DC transformer I got out of a radio. I removed the rectifing (spelling?) circuit. So why is it that the transformer still only responds to AC input and not DC? I basically want a transformer that can take low voltage (aroung 6-12v DC) and step it up to 400VDC. Any suggestions or help?

- The transformer only responds to AC voltage and is basically a short to DC voltage. In order to achieve your desired result, you'll need to configure a voltage multiplier circuit and it's much better to keep your AC input, installing capacitors in line with 110 Vac input and in parallel across your resistive load. Performing this feat with 6-12Vdc would involve switching circuits across capacitor banks and little or no available current.

- Q:I know that in a step-down transformer if I have 10 turns on the primary coil and 5 turns on the secondary coil that the voltage gets reduced by half and the current gets doubled, but is there any other significance?

- Often wondered this myself. There must be a reason why you get transformers with 1000 turns on the primary, and 500 turns on the secondary. If there wasn't a good reason why would manufactures bother putting more than 2 turns on the primary and a single turn on the secondary? The ratio remains the same! Think it could be something to do with the impedance the transformer offers to the input, and output circuits. impedance is kind the AC equivalent of resistance. If it's high then there'll be a fair impedance(resistance to the instantaneous flow of current for a given instantaneous voltage. More turnslonger wirehigher impedance? Matching of impedance between circuits can be important to ensure maximum efficiency/preventing echos etc.

- Q:How can the locations and polarity of the windings be tested on the various legs of a core when it has 2 open(circuited) three pahse windings (III and iii)?what measurements are required , assuming that the transformer is so enclosed that only the 12 winding terminals are visible?Ohmmeter , voltmeters , a single phase voltage supply are available.

- It sounds like you have a three phase transformer. In the cover plate there normally is a drawing to guide you on what you want to do. Most trans formers can have input voltages of 440 volts in to 240 ouput. but some can provide 115 volts on the output if wired correctly. Any transfomer compnay website provide wiring drawings that pretty match everyones transformers. Contact the manufacturer of the transformer for instructions.

- Q:HiCan anybody help with the below question?A 400V, 3 phase supply is connected through a 3 phase loss-free transformer of ratio 1:1, which has its primary connected in mesh and secondary in star, to a load comprising three 20 ohm resistors connected in deltaCalculate the currents in the transformer windings, in the resistors and in the lines to the supply and the load. Find also the total power supplied and the power dissipated by each resistor.Thanks in advance

- the only reason that i will think of is is an electric powered gadget is that it does paintings, It consumes power (losses) and it particularly is hooked as much as the provision?? besides the indisputable fact that I too have in no way heard if them being spoke of as a gadget in 40 4 years interior the commerce

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JDXF-35 TA,TH GY W1,W2,W3 Voltage Transformer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords