Hot Rolled Mild Steel Round Bar Q235 Q345 Q235B Q345B

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Mild Steel Round Bar Q235 Q345 Q235B Q345B

Products Details

Diameter(mm) | Φ6 ,Φ8,Φ10,Φ12,Φ13,Φ14,Φ16,Φ18,Φ20,Φ22,Φ25,Φ28,Φ32, |

Length(m) | Unfolded / Straight Bundles weighing upto 2 Metric Tons and lengths is 6 Meters upto 15 Meters or according customers require |

U Shaped folded Bundles weighing up to 2 Metric Tons and lengths is 12 Meters | |

Rounded Coils ~ up to 2 Metric Ton Coils for Bending / Cutting Machine use. | |

Standard | GB(HRB335/HRB400/HRB500); |

BS4449 -1997 GRADE 250B, 460B; BS4449-2005 GRADE 500B; | |

ASTM A615 GRADE 40,GRADE60,GRADE75; ASTM A706; | |

DIN488-1 420S/500S, BST500S | |

JIS G3112 SD35, SD40, SD50,SD390 | |

NFA 35016 FE E 400, FE E 500 | |

CA 50/60 | |

GOST A3 R A500C | |

Surface finished | Screw-thread |

Epoxy coating | |

Galvanized coating | |

Production facility | Imports of production equipment from Italy |

Production capacity | 50,000 MT/month |

Payment term | T/T or 100% L/C at sight |

Package | By bundles. One bundles about 2-3tons |

Weight

------------------------------------------------------------------------------------------------------------------

| Dia mm | Theoretical weight kg/m | Dia mm | Theoretical weight kg/m |

| 12 | 0.888 | 25 | 6.85 |

| 14 | 1.21 | 28 | 4.83 |

| 16 | 1.58 | 29 | 5.06 |

| 18 | 2.00 | 32 | 6.31 |

| 19 | 2.235 | 36 | 7.99 |

| 20 | 2.47 | 40 | 9.87 |

| 22 | 2.98 | 50 | 15.42 |

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

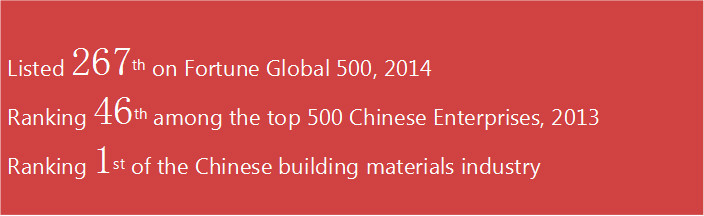

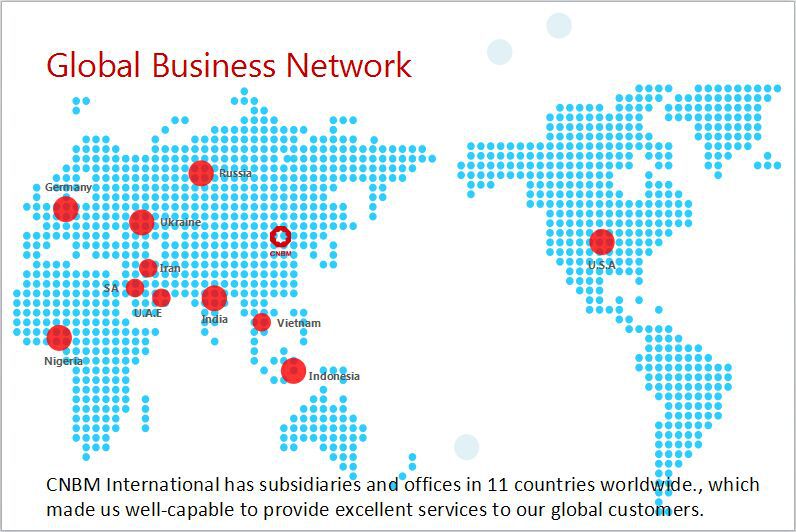

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q:Are steel round bars suitable for plumbing applications?

- Yes, steel round bars are suitable for plumbing applications. They are commonly used in plumbing systems for their strength, durability, and resistance to corrosion. Steel round bars can be easily shaped and welded to create various plumbing components such as pipe fittings, supports, and brackets. Additionally, their high tensile strength makes them capable of withstanding the pressure and load requirements in plumbing systems.

- Q:What is the minimum tensile strength of steel round bars?

- The minimum tensile strength of steel round bars can vary depending on the specific grade or type of steel being used. However, common steel grades typically have a minimum tensile strength of around 400 MPa (megapascals) or 58,000 PSI (pounds per square inch).

- Q:Can steel round bars be used in the manufacturing of couplings?

- Yes, steel round bars can be used in the manufacturing of couplings. Steel round bars are commonly used in various industrial applications due to their strength, durability, and versatility. Couplings are mechanical devices that connect two shafts together in order to transmit power or allow for the misalignment of the shafts. Steel round bars can be machined, formed, or welded to create different types of couplings, such as rigid couplings, flexible couplings, or universal couplings. The use of steel round bars in manufacturing couplings ensures that the couplings have high tensile strength and can withstand heavy loads and torque. Additionally, steel round bars can be heat-treated to enhance their mechanical properties, making them suitable for different operating conditions and environments. Therefore, steel round bars are a popular choice for the manufacturing of couplings.

- Q:What are the different types of steel round bars used in the automotive steering systems?

- There are several types of steel round bars used in automotive steering systems, including carbon steel, alloy steel, and stainless steel. Carbon steel round bars are commonly used due to their affordability and high strength properties. Alloy steel round bars are used when higher strength and durability are required, as they have additional alloying elements such as chromium, nickel, and molybdenum. Stainless steel round bars are preferred for their corrosion resistance properties, making them suitable for steering components exposed to harsh environments or moisture.

- Q:Which is stronger, steel pipe or round steel? Which is good at bending?

- The strength of the steel pipe is slightly lower, but its weight is light, so as long as the wall thickness is reasonable, the experienced designer uses steel pipe instead of round steel.Like me, that's it

- Q:Can steel round bars be used for making oil and gas industry components?

- Yes, steel round bars can be used for making oil and gas industry components. Steel round bars are commonly used in the oil and gas industry due to their high strength, durability, and resistance to corrosion. These components require materials that can withstand harsh environments, high pressures, and extreme temperatures, and steel round bars meet these criteria. They are commonly used to manufacture various components such as valves, flanges, pipes, and fittings, which are vital for the functioning of the oil and gas industry. Additionally, steel round bars can be easily machined and welded, allowing for the fabrication of complex shapes and structures required in this industry. Overall, steel round bars are a reliable and widely used material for making oil and gas industry components.

- Q:How do you calculate the strength of a steel round bar?

- The strength of a steel round bar is typically calculated using the formula for tensile strength, which is the maximum amount of tensile stress that a material can withstand before breaking. This is determined by dividing the maximum load applied to the bar during a tensile test by its cross-sectional area.

- Q:How are steel round bars inspected for quality?

- Steel round bars are inspected for quality through various methods to ensure that they meet the required standards. The inspection process typically involves both visual examination and testing procedures. Visual inspection is the first step in assessing the quality of steel round bars. Qualified inspectors visually examine the bars for surface defects such as cracks, scratches, dents, or any other irregularities that may affect the structural integrity or performance of the bars. Additionally, dimensional inspection is conducted to verify the diameter, length, straightness, and overall shape of the round bars. This is done using precision measuring instruments to ensure that the bars meet the specified tolerances and requirements. Aside from visual inspection, various testing methods are employed to evaluate the mechanical properties and chemical composition of the steel round bars. The most common testing procedures include: 1. Tensile Testing: This test measures the strength and ductility of the steel bars by subjecting them to tension until they fracture. It helps determine the ultimate tensile strength, yield strength, and elongation of the material. 2. Hardness Testing: It is performed to assess the hardness of the steel round bars, which is an indicator of its resistance to deformation or wear. The most commonly used methods for hardness testing are Rockwell, Brinell, and Vickers hardness tests. 3. Ultrasonic Testing: This non-destructive testing method uses high-frequency sound waves to detect any internal defects or discontinuities in the steel bars. It helps identify flaws such as cracks, inclusions, or voids that may negatively impact the material's quality. 4. Chemical Analysis: Steel round bars undergo chemical analysis to determine the chemical composition and ensure it meets the required specifications. This analysis helps verify the percentages of different alloying elements present in the steel, ensuring it has the desired properties. All these inspection methods are conducted by trained professionals or certified third-party inspectors who are knowledgeable about the specific industry standards and guidelines. By combining visual examination and precise testing techniques, the quality of steel round bars can be thoroughly assessed, ensuring they are fit for their intended applications.

- Q:What is the difference between a bright and a black steel round bar?

- The main difference between a bright and a black steel round bar is the surface finish. A bright steel round bar has a smooth and shiny surface due to the additional processing steps it undergoes, such as pickling or cold drawing. On the other hand, a black steel round bar has a rough and dark surface due to the absence of these additional processing steps. Additionally, the black steel round bar may also have a coating of oil or rust inhibitor to protect it from corrosion.

- Q:Can steel round bars be used for shafts or axles?

- Indeed, shafts or axles can make use of steel round bars. In a multitude of industries, including automotive, machinery, and construction, steel round bars are frequently employed due to their robustness, longevity, and adaptability. Their selection for shafts or axles often stems from their capacity to endure substantial loads, furnish dependable support, and endure wear and tear. By virtue of being machinable and amenable to heat treatment, steel round bars can be customized to meet specific prerequisites, rendering them well-suited for deployment as shafts or axles in a wide range of applications where strength and dependability are paramount, such as vehicles, industrial apparatus, and rotating machinery.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Mild Steel Round Bar Q235 Q345 Q235B Q345B

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords