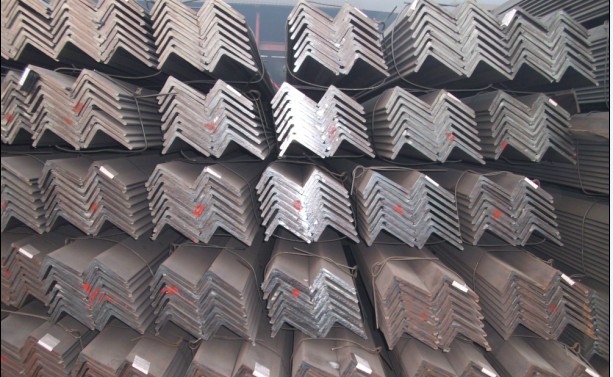

Hot rolled angle steel ASTM A36 or GB Q235 20-250mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:Specificationsangle steel angle steel angle steel agle steel angle steel

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse. Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two. Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 12.5cm for large angle steel, 12.5cm - 5cm for the medium angle, length of 5cm for smallangle. Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series. Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m. Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125 Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc. 1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load. 2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request. 3. Marks: Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port. Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer. If loading by container the marking is not needed, but we will prepare it as customer request. |

- Q:How do you calculate the shear force on a loaded steel angle?

- In order to determine the shear force on a loaded steel angle, one must take into account the applied load, the angle's geometry, and the steel's material properties. The term "shear force" refers to the force that acts parallel to the angle's cross-sectional area. Firstly, it is crucial to ascertain the applied load that is acting upon the steel angle. This load can be either concentrated, distributed, or a combination of both. It is of utmost importance to accurately determine the load's magnitude and location. Subsequently, the steel angle's geometry should be considered. The angle consists of two legs, each possessing specific measurements of length, width, and thickness. Precise measurements of these dimensions are necessary. Once the load and angle dimensions are obtained, the shear force can be calculated by employing the following formula: Shear Force = Load / Cross-sectional Area To calculate the cross-sectional area, one must take into account the angle's shape. Typically, the cross-sectional area of a steel angle is calculated by adding together the areas of both legs and then subtracting the area of the corner radius. In the case of unequal legs, the cross-sectional area can be calculated by adding together the areas of the longer and shorter legs and subtracting the area of the corner radius. After determining the cross-sectional area, divide the applied load by this value to determine the shear force acting on the loaded steel angle. It is important to note that the aforementioned calculation assumes that the steel angle is solely subjected to pure shear. In practical scenarios, additional factors such as bending moments and torsion may need to be taken into consideration, which would necessitate more intricate calculations and analysis. Therefore, it is advisable to consult relevant design codes, principles of structural engineering, or seek the guidance of a professional engineer for accurate and reliable results.

- Q:Can steel angles be recycled?

- Indeed, it is possible to recycle steel angles. Steel, being one of the most recycled materials globally, also applies to steel angles. Once steel angles are deemed unnecessary or have fulfilled their lifespan, they can undergo collection, processing, and transformation into fresh steel products. By recycling steel angles, the conservation of natural resources, reduction of energy consumption, and minimization of waste are achieved. Consequently, steel angles prove to be an environmentally conscious and sustainable option for construction and various other applications.

- Q:What is the cost of a steel angle?

- The cost of a steel angle can vary depending on various factors such as size, thickness, and market conditions. It is best to check with local suppliers or online retailers to get an accurate and up-to-date price for a specific steel angle.

- Q:Are steel angles suitable for manufacturing support brackets for pipes?

- Yes, steel angles are suitable for manufacturing support brackets for pipes. Steel angles are known for their strength, durability, and load-bearing capacity, making them an ideal choice for supporting and securing pipes in various applications. The angled shape of steel angles provides stability and structural integrity to the support brackets, ensuring that the pipes remain securely in place. Additionally, steel angles can be easily fabricated, welded, and customized to meet specific requirements, making them a versatile and cost-effective option for manufacturing support brackets for pipes.

- Q:Can steel angles be used in the construction of hospitals?

- Yes, steel angles can be used in the construction of hospitals. Steel angles are commonly used in construction projects as they provide structural support and stability. In the construction of hospitals, steel angles can be used in various applications such as framing, support beams, trusses, and reinforcement for walls and floors. Steel angles are known for their strength, durability, and resistance to fire, making them suitable for withstanding the high demands and safety requirements of hospital buildings. Additionally, steel angles can be easily fabricated and manipulated to fit the specific design and structural requirements of a hospital, allowing for flexibility in construction. Overall, steel angles are a reliable and versatile material that can be effectively used in the construction of hospitals.

- Q:What is the difference between equal and unequal steel angles?

- Equal and unequal steel angles are structural steel components that are commonly used in construction and industrial applications. The main difference between these two types of angles lies in their dimensions and properties. Equal steel angles, also known as L-shaped angles, have equal sides and equal angles between them. They are typically used to provide support and stability in various structures, such as buildings, bridges, and machinery. The equal sides of these angles allow for symmetrical distribution of load and provide balanced strength in all directions. This makes them ideal for applications where equal support is required on both sides. On the other hand, unequal steel angles have different side lengths and different angles between them. These angles are used when there is a need for uneven load distribution or when a specific angle is required for a particular application. The longer side of the angle is typically used for load-bearing purposes, while the shorter side may be used for additional support or as a connection point. Unequal angles are commonly used in the construction of frames, brackets, and supports where unequal load distribution is expected. In terms of properties, both equal and unequal steel angles are made from carbon steel, which provides good strength and durability. These angles are typically hot-rolled or cold-formed, depending on the manufacturing process. Hot-rolled angles are produced at high temperatures, resulting in a rough surface finish but improved mechanical properties. Cold-formed angles, on the other hand, are made by bending and shaping the steel at room temperature, resulting in a smoother surface finish but slightly lower mechanical properties. In summary, the main difference between equal and unequal steel angles lies in their dimensions and load distribution capabilities. Equal angles have equal sides and are used for symmetrical load distribution, while unequal angles have different side lengths and are used for uneven load distribution or specific angle requirements. Both types of angles are made from carbon steel and are commonly used in construction and industrial applications.

- Q:How are steel angles installed on concrete structures?

- To reinforce and support concrete structures, steel angles are commonly utilized. The installation of steel angles on concrete structures entails several steps. To begin, the concrete surface must be prepared. This entails thoroughly cleaning the surface and eliminating any debris or loose material. The concrete must be in good condition, devoid of cracks or other structural problems. Next, the steel angles must be positioned and marked on the concrete surface. Typically, a measuring tape and chalk line are used for this purpose. Based on the structural requirements, the angles are usually placed at specific intervals and locations. Once the positions have been marked, the concrete surface needs to be drilled. This is accomplished using a drill and a masonry bit appropriate for the size of the anchor bolts or fasteners that will be employed. It is crucial to drill the holes to the required depth to ensure a secure and stable installation. After the holes have been drilled, anchor bolts or fasteners are inserted into them. These bolts or fasteners are specifically designed for securely fastening steel angles to concrete surfaces. Usually made of steel, they possess a threaded end that enables them to be firmly tightened into the concrete. Once the anchor bolts or fasteners have been inserted, the steel angles are positioned and aligned with the marked locations on the concrete surface. The angles are then secured to the concrete by tightening the nuts on the anchor bolts or fasteners. Finally, the installation is examined for accuracy and stability. The angles should be securely attached to the concrete surface and should not move or shift when pressure is applied. Additional adjustments or tightening may be necessary to ensure a dependable and secure installation. All in all, the process of installing steel angles on concrete structures involves meticulous preparation, drilling, anchoring, and securing. This guarantees that the angles deliver the necessary strength and support required for the specific application.

- Q:How do you determine the required length of a steel angle for a specific application?

- In order to determine the necessary length of a steel angle for a particular application, several factors must be taken into consideration. 1. Load requirements: The first step is to calculate the maximum load that the angle will need to support. This includes the weight of the object or structure it will be holding, as well as any additional live loads like wind or snow. By determining the load requirement, you can determine the appropriate strength and size of the angle. 2. Structural analysis: Conduct a structural analysis of the intended application to determine the forces and stresses that will be applied to the steel angle. This analysis will help determine the necessary properties of the angle, such as its moment of inertia, section modulus, and bending capacity. 3. Material selection: Select the appropriate steel material for the application based on its mechanical properties, such as yield strength, tensile strength, and ductility. Different grades of steel offer varying levels of strength and durability, so it is important to choose the right material to ensure the angle can withstand the required loads. 4. Design codes and standards: Refer to relevant design codes and standards, such as those established by organizations like the American Institute of Steel Construction (AISC) or the Eurocode, to ensure compliance with industry regulations and guidelines. These codes provide specific formulas and procedures for calculating the required length and size of the angle based on the load and structural analysis. 5. Fabrication considerations: Take into account any limitations or constraints in the fabrication process that may affect the length of the steel angle. For instance, standard lengths of steel angles may be available, so it may be necessary to choose a length that is readily accessible or can be easily obtained through custom fabrication. 6. Consultation with professionals: If there are any uncertainties in determining the required length of a steel angle, it is recommended to seek advice from a structural engineer or a professional experienced in steel design. They can offer expert guidance and ensure that the angle is appropriately sized and designed for the specific application. By considering these factors and following a systematic approach, it is possible to determine the necessary length of a steel angle that fulfills the specific requirements of the application.

- Q:What is the process of punching holes in steel angles?

- The process of punching holes in steel angles typically involves using a specialized machine called a punch press. The steel angle is securely clamped into the machine, and then a punch and die set is aligned with the desired location for the hole. The machine is then activated, and the punch is driven into the steel angle, creating a hole. This process can be repeated multiple times to create multiple holes in the steel angle, if needed.

- Q:Are steel angles suitable for architectural applications?

- Indeed, architectural applications are well-suited for steel angles. In construction and architectural projects, steel angles are frequently employed due to their adaptability, robustness, and visual allure. They serve a multitude of purposes, including the formation of structural frames, supports, connections, and even decorative elements. Architects are provided with a wide range of options when it comes to steel angles, as they are available in various sizes, thicknesses, and finishes, enabling the selection of the most appropriate choice in accordance with specific design requirements. Moreover, steel angles can be effortlessly welded, drilled, and manipulated to accommodate diverse angles and shapes, thus rendering them a versatile and economical alternative for architectural applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot rolled angle steel ASTM A36 or GB Q235 20-250mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords