Hot Dipped Galvanized Welded Gabion Hot Sale Superior Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

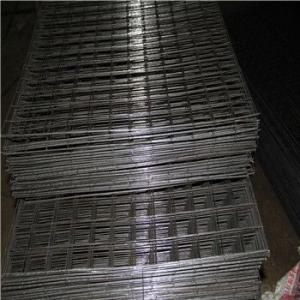

Welded gabion box is widely used in retaining wall structures, rockfall and soil protection and so on. Welded gabions are filled on site with hard and durable stone to form mass gravity structures. And welded gabions are quicker and simpler to install than woven mesh gabions.

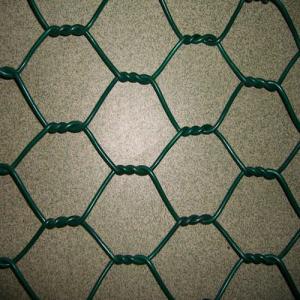

Welded gabion box is manufactured from cold steel wire for tensile strength. It is electrically welded together then hot dipped galvanized or PVC coated, ensuring a longer life. There are galvanized welded gabion and welded PVC gabions. Gabion boxes are designed on the principle of mass earth retaining wall. The strength of the wire mesh helps to with- stand the forces generated by the retained soil.

Specifications of welded gabion box:

Nominal Box sizes m) | No. of diaphragms (no.) | Capacity per box(m3) |

1.0x1.0x0.5 | Nil | 0.50 |

1.0x1.0x1.0 | Nil | 1.00 |

1.5x1.0x0.5 | Nil | 0.75 |

1.5x1.0x1.0 | Nil | 1.50 |

2.0x1.0x0.5 | 1 | 1.00 |

2.0x1.0x1.0 | 1 | 2.00 |

3.0x1.0x0.5 | 2 | 1.50 |

3.0x1.0x1.0 | 2 | 3.00 |

4.0x1.0x0.5 | 3 | 2.00 |

4.0x1.0x1.0 | 3 | 4.00

|

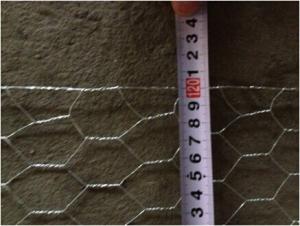

Standard wire diameter (mm)

Heavily Galvanised or zinc coated wire 2.20, 2.50, 2.70, 3.00, 4.00, 5.00.

Polymer coated on Heavily Galvanised or zinc coated wire 2.5/2.8, 2.7/3.0, 3.0/3.3, 4.0/4.3, 5.0/5.3.

Welded gabion box advantages:

Blends easily and harmoniously with the natural surroundings.

Low cost alternative to concrete or masonry structures.

Very high resistance to natural forces due to better tensile strength.

Can withstand any unpredictable movement or settlement without loss of stability.

Simple and speedy installation, making it cost effective.

Quality finish and appearance is more aesthetically pleasing.

More rigid than woven mesh resulting in a more uniform finish when built.

Quicker and cheaper to install than Woven Mesh gabions because no pre-stretching required.

Special gabions sizes and mesh such as gabions with 4mm front mesh and 3mm mesh else can be available.

Application

1. Control and guide of water or flood

2. Preventing of rock breaking

3. Rock fall protection

4. Water and soil protection

5. Bridge protection

6. Strengthening structure of soil

7. Protection engineering of seaside area.

8. Port project

9. Keep off dust wall

10.Roadway protection.

Packaging Detail: Pallet, in bundle, or as required.

Delivery:7-15 days

Trade & Market Main Markets: Central America

Africa

Eastern Europe

Mid Eas

Northern Europe

Western Europe

North America

Total Annual Sales Volume: US$10 Million - US$50 Million

Export Percentage: 71% - 80%

Factory Information Factory Size (Sq.meters): 30,000-50,000 square meters

Factory Location: Wire mesh industrial zone ,anping china

Number of Production Lines: 8

Number of R&D Staff: 11 - 20 People

Number of QC Staff: 31 - 40 People

Management Certification: ISO9001

We cooperate with many countries, such as Brazil, Russia, Poland, Australia

Hope you can contact and I will offer you the best price , will do my best to serve you !

Why do you make business with our company?

Manufacturer

Superior quality & Good service

Fast delivery & Competitive price

ISO9001:2008

Special size is available

Welcome customers' inquiry!

- Q:What is the barbed wire in the cable line?

- If there is no such network, the TV signal is highly susceptible to some of the frequency of interference, resulting in increased noise on the screen, and even lead to poor synchronization.

- Q:Is it possible to protect the radiation around the computer with a wire mesh?

- Then this said, the so-called CPU radiation will not be where to go with the sun's almost what I think.

- Q:Construction in the wall and the beam at the junction of nail wire mesh what role

- To enhance the capacity of some of the ground, in the processing workshop, garage and other places on the ground load larger room, wire mesh can improve the overall structure of the ground layer strength, to avoid the ground cracking, fall and so on.

- Q:How does proe draw wire mesh?

- With a way to scan it to a roughness (wire diameter), because the barbed wire is two cross, so the mirror in the center of a mirror out of the two wire will be created into a group, (selected - right - group )

- Q:How does the "jagged" on the back of the knife cut the barbed wire?

- Knife knife cutting barbed wire as shown: the knife hole slightly and the sheath of the protruding part of a combination on the line (to M86 Saber and AK Army knife, for example)

- Q:What is the use of wire

- Iron is a long time will rust. Iron easily rust, in addition to its chemical nature of lively, but also with the outside world conditions also have a great relationship.Water is easy to rust the iron one of the material, iron into the water

- Q:Wall tiles how to hang iron wire mesh

- In the wall more nails, and then use the cement bonded wire mesh can solve the above problems;

- Q:Why is the effect of electromagnetic radiation shielding with wire mesh?

- Do not believe ah, this can drop, who also buy shielding materials ah; direct purchase of barbed wire on the line.

- Q:Barbed wire fence is what the iron ring

- There are blue, green, yellow and other colors. Uses: for grassland boundaries, railways, highways, such as isolation protection.

- Q:Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The mesh count refers to the number of holes of 2.54 cm. The unit used to express the mesh in the mesh product specification is hole / cm or line / cm. In countries and regions using imperial units of measurement, the mesh size is expressed in holes / inch or lines / inch.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dipped Galvanized Welded Gabion Hot Sale Superior Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords