Hot-dip Zinc Coating Steel in Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

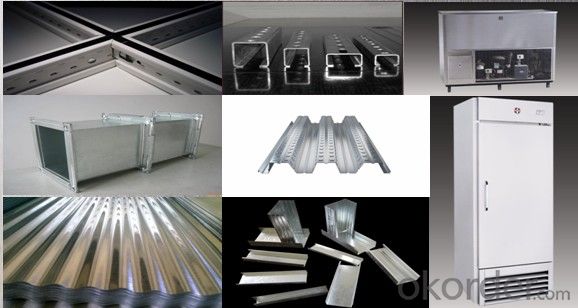

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils used in the production of elevator components?

- Steel coils are used in the production of elevator components to manufacture various structural and mechanical parts. These coils are typically formed, shaped, and cut to create components such as elevator guide rails, brackets, frames, and support structures. The high strength and durability of steel make it an ideal material for these components, ensuring the safety and reliability of elevators.

- Q:What are the different methods of coil slitting for precision cuts?

- Coil slitting is a process used to cut large coils of material, such as steel, into narrower strips with precise dimensions. There are several methods of coil slitting for achieving precision cuts, each offering unique advantages and suitable for different applications. 1. Rotary Shear Slitting: This is the most common method used for coil slitting. It involves passing the coil through rotating circular knives that create two or more strips by shearing the material. The blades can be set at different distances apart to achieve the desired width of the strips. Rotary shear slitting offers high precision and is capable of producing smooth, burr-free edges. 2. Drag Knife Slitting: In this method, a knife with a drag or tangential orientation is used to cut the coil. The knife moves in a controlled path, following the contour of the material and producing accurate cuts. Drag knife slitting is suitable for materials with irregular shapes and is often used in the textile industry for cutting fabrics. 3. Scissor Slitting: Scissor slitting involves the use of two blades that move against each other in a scissor-like motion to cut the coil. This method is commonly used for thinner materials and provides excellent control over the cutting process. Scissor slitting is ideal for achieving precise cuts in materials that are prone to deformation or wrinkling. 4. Razor Slitting: Razor slitting utilizes a single razor blade or multiple razor blades in a holder to cut the coil. The blade(s) are positioned perpendicular to the material and slice through it. This method is particularly effective for cutting stretchy or delicate materials, such as plastic films or paper, as it minimizes the risk of tearing or deforming the material. 5. Crush Cutting: Crush cutting involves using a hardened steel roller or an anvil against a softer material, such as foam or rubber, to cut the coil. The pressure applied causes the material to deform and split along the desired cutting line. Crush cutting is suitable for materials that are difficult to cut with sharp blades and can produce precise, clean cuts. Overall, the choice of coil slitting method depends on the material being cut, the desired precision, and other requirements of the specific application. Each method offers its own benefits and can be tailored to meet specific cutting needs, ensuring accurate and efficient coil slitting processes.

- Q:doesnt steel rust?

- Iron mixed with other metals:

- Q:What is the role of steel coils in the automotive industry?

- Steel coils play a crucial role in the automotive industry as they are the primary raw material used for manufacturing various components and parts of vehicles. These coils are typically made from high-quality steel and are formed into a continuous strip, which can be easily processed and shaped into desired automobile parts. One of the key applications of steel coils in the automotive industry is in the production of body panels and frames. These coils are processed through stamping and forming techniques to create panels such as doors, hoods, fenders, and roofs. Steel coils provide the necessary strength, durability, and rigidity required to withstand external forces and protect the passengers and other components of the vehicle. Moreover, steel coils are also utilized in the manufacturing of various structural components of automobiles. Chassis, suspension systems, and other critical parts such as engine cradles and brackets are typically produced using steel coils due to their excellent mechanical properties. Steel coils possess high tensile strength, which enhances the overall structural integrity of the vehicle and ensures safety. Additionally, steel coils are integral in the production of automotive springs, which play a vital role in the suspension system. Coil springs, leaf springs, and torsion bars are commonly utilized in vehicles to absorb shocks, provide stability, and maintain proper ride height. The use of steel coils in these applications ensures optimal performance, durability, and longevity of the suspension system. In summary, steel coils are essential in the automotive industry for their versatility, strength, and durability. They are used in the manufacturing of body panels, frames, structural components, and suspension systems. The utilization of steel coils in these applications contributes to the overall safety, reliability, and performance of vehicles.

- Q:How are steel coils inspected for flatness?

- Steel coils are inspected for flatness using various methods, such as visual inspection, measuring the crown or center buckle, and conducting a straight edge test. These techniques help assess any deviations or unevenness in the coil's surface, ensuring that it meets the required flatness standards.

- Q:Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- i think steel would be better since there isn't a lot of mithril ore and it would take a lot of time to mine it and it will take also 4 coals to make a mith bar and 2 only for a steel bar

- Q:nylon sounds alot better but i want to keep the acoustic i have now. Is it proper to put nylon on an acoustic guitar meant for steel strings?

- Nylon Strings For Acoustic Guitar

- Q:what do they use to make stainless steel?and can stainless steel be melted again and again without losing it's Specifications

- Components Of Stainless Steel

- Q:I need the measurements of the height and hypotenuse of the first drop in the Steel Dragon 2000. I couldn't find it anywhere. It would be great if you could also show me the website where you got your answer. Thanks! =]*The hypotenuse is the length of the drop.*

- Steel Dragon 2000 is a roller coaster at Nagashima Spa Land Amusement Park in Mie Prefecture, Japan. Built by Morgan Manufacturing, this gigacoaster opened, appropriately, in 2000 - The Year of the Dragon in the Far East. It debuted only months after Millennium Force and surpassed the Cedar Point coaster as the world's tallest complete-circuit coaster. It also set a record for longest track length - 8133 feet, 2 inches (2479 m), which it currently holds. Coaster Facts * Steel Dragon 2000 is the tallest coaster to utilize a traditional chain lift. Because of the length of the lift hill, two chains are used - one for the bottom half and one for the top half. A single chain would have been excessively long and heavy, at least twice the weight of one of the trains. As a result, two trains can safely occupy the lift simultaneously. * The building of Steel Dragon 2000 required far more steel than other coasters for earthquake protection. This put the cost of the coaster at over $50,000,000. * On August 23, 2003, Steel Dragon 2000 was involved in an accident during a run in which one of its trains lost a wheel. The coaster did not operate during the 2004 and 2005 park seasons. It reopened September 3, 2006.

- Q:Are Steel buildings Fire Resistant, just want to know as I am going to owe it . Suggestions required…………..

- What burns in a building are mostly the furnishings and interior, not the frame it's made of. Steel buildings are more expensive to insure against fire than wood frame buildings, because in a fire more steel is damaged by warping and distortion than would happen in a wood-framed structure, and wood structures are easier (and cheaper) to repair. Of course, if everything in a building was non-flammable, fire would never occur. That doesn't usually happen, though, and it's all the flammable stuff that most buildings house inside that burns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-dip Zinc Coating Steel in Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords