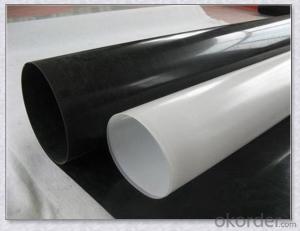

High-Density Polyvinyl Chloride Hdpe Geomembrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Impermeable Geomembrane HDPE for Shrimp Pond is mainly made of virgin HDPE with blow molding technique. Its main function is to prevent the liquid leakage and gas volatilization.

Features:

1.It can effectively make the concentrated stress diffuse, transfer or decompound, and prevent the soil mass against the destruction of outside force.

2.It can prevent the mixture of sandstone, soil mass and concrete of upper and lower layers.

3.Its mesh is hard to jam by virtue of the compliancy and motility of the reticulation formed by indefinite form fibrous tissue.

4.High water permeability-it can keep good water permeability even in the pressure of soil and water.

5.Corrosion resistant-it is made from polypropylene fiber or terylene or other chemical fiber, featuring resistance to acid and alkali and oxidation, non-corroding, no worm-eaten.

6.Easy construction-low weight, easy operation, simple construction

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geotextiles be used in retaining wall reinforcement?

- Yes, geotextiles can be used in retaining wall reinforcement. Geotextiles are often used as a separation and filtration layer in retaining walls to prevent soil erosion and improve their stability. They can help distribute loads, reduce soil movement, and enhance the overall performance and durability of the retaining wall system.

- Q:How do geotextiles improve the performance of tunnels?

- Geotextiles improve the performance of tunnels by providing reinforcement and stabilization to the surrounding soil, preventing soil erosion and subsidence. They also act as a barrier to prevent the migration of fine particles, improving the overall durability and longevity of the tunnel structure.

- Q:The technical parameters of woven geotextile

- Test items / specifications 0400 Remarks breaking strength (longitudinal) KN / m ≥ 17. Breaking strength (horizontal) KN / m ≥ no special requirements by the meridional 0.7 / 1 longitudinal and transverse elongation at break% ≤ 25 vertical and horizontal trapezoidal torn Strength, KN ≥ 0.180.200.270.340.410.480.600.72 vertical and horizontal CBR top breaking strength, KN ≥ 1.41.62.43.24.04.86.07.5 equivalent aperture O95 (O95) mm0.07-0.5 vertical permeability coefficient cm / sK × (10-1-10-4) K = 1.0-9.9

- Q:How do geotextiles help with siltation control in construction sites?

- Geotextiles help with siltation control in construction sites by acting as a barrier that prevents the movement of soil particles while still allowing water to pass through. They are typically placed on the ground surface or used as erosion control blankets, effectively reducing erosion and sediment runoff. This helps to minimize the amount of silt and sediment that enters nearby water bodies, maintaining water quality and protecting the surrounding environment.

- Q:How do geotextiles help with sediment retention in sediment basins?

- Geotextiles help with sediment retention in sediment basins by acting as a physical barrier that traps sediment particles while allowing water to pass through. They prevent erosion and sediment movement by stabilizing the soil, reducing the flow velocity of water, and promoting sediment settlement within the basin.

- Q:Geotextile detection frequency

- First according to customer requirements grams / square meters, thickness, width, with or without the use of chemical fiber requirements, proofing, and the proofing process parameters, including feed speed, other machines and other parameters of the speed record, Do twenty to ten meters, to test, if qualified, to do so, a lot of bulk, do a few days and then try to seize what the general geotextile manufacturers themselves to prepare several commonly used testing equipment,

- Q:What are the different types of geotextiles?

- There are several types of geotextiles, including woven geotextiles, non-woven geotextiles, and knitted geotextiles. Each type has its own unique properties and characteristics that make them suitable for various applications in civil engineering, construction, and environmental projects.

- Q:How to apply geotextile soil

- General geotextile cloth in the drainage layer above the geotextile covered with soil

- Q:What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects can vary depending on the specific project requirements. However, some common specifications include the desired tensile strength, puncture resistance, and permeability of the geotextile. Additionally, the required thickness, weight, and filtration efficiency may also be specified. It is important to consult the project specifications and consider factors such as soil type, groundwater conditions, and anticipated loads to determine the appropriate specifications for geotextiles in subsurface drainage projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Density Polyvinyl Chloride Hdpe Geomembrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords