Polyester Geogrid for Road Construction with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid Description

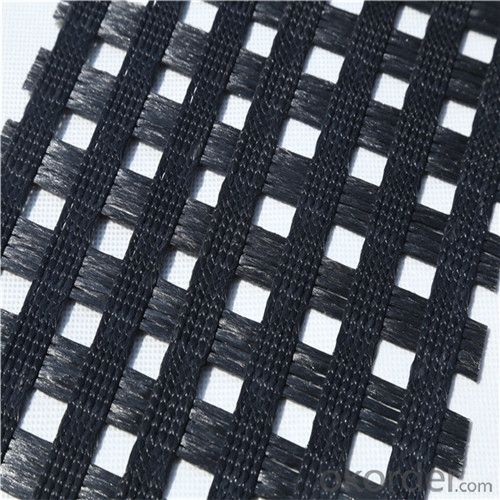

Polyester Geogrid chooses polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending between warp and weft direction.

Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction, then it forms into a mesh size product after coated with high quality oil-soluble PVC.

Polyester Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN, 150-150KN, 200-200KN,

Roll Size: 3.95x100m, as request,

Polyester Geogrid Property

1) High tensile strength

2) Low elongation

3) Anti-erosion, anti-aging

4) Good affinity with base material

5) Light weight, water drainage

Polyester Geogrid Application

1) Roadbed reinforcement in highway, railway and municipal road.

2) Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

3) Roadbed slope reinforcement, retaining wall reinforcement.

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:Can geogrids be used in reinforced earth structures?

- Yes, geogrids can be used in reinforced earth structures. Geogrids are commonly employed as reinforcement materials in applications such as retaining walls and slopes to enhance the stability and strength of the structure. They provide reinforcement by distributing loads, reducing soil movement, and increasing overall stability.

- Q:How do geogrids improve the performance of geosynthetic filters?

- Geogrids improve the performance of geosynthetic filters by enhancing their stability and preventing soil erosion. The geogrids provide a reinforcing structure that enhances the filter's tensile strength and prevents the filter from collapsing under heavy loads. This helps to maintain the integrity of the filter and ensures efficient water flow, preventing clogging and maintaining proper drainage. Additionally, geogrids improve the overall durability and longevity of geosynthetic filters, enhancing their effectiveness in various civil engineering and environmental applications.

- Q:Can geogrids be used in soil stabilization for parking lots?

- Yes, geogrids can be used in soil stabilization for parking lots. Geogrids are commonly used to reinforce and strengthen soil, preventing its movement and improving load-bearing capacity. By installing geogrids, parking lots can resist deformation and withstand heavy traffic, ensuring long-term stability and durability.

- Q:Can geogrids be used in landfill applications?

- Yes, geogrids can be used in landfill applications. Geogrids are commonly used in landfill construction to improve the stability and performance of the landfill liner system. They help in reducing the potential for soil erosion, enhancing the load-bearing capacity, and providing reinforcement to the liner system.

- Q:Urgent need!!

- (1) due to the existence of joints and cracks, the old cement concrete pavement as the base of the overall strength is reduced, and under the action of external forces, the asphalt overlay in the three-dimensional stress state. The vehicle passing adiscontinuous board, because the joints and cracks on both sides of the adjacent plate reflecting cracks of vertical displacement difference, asphalt overlay in the corresponding position of the larger shear stress, the shear stress is the main reason of asphalt pavement reflection cracks produced. Usually referred to as the load type reflective crack.(2) due to the exposure of the pavement in the atmosphere, the asphalt overlay and the old cement concrete face have the shrinkage and the temperature stress. Because of the Old Cement Concrete Pavement Stress in the joints is not continuous, so the asphalt overlay and bear it and the old pavement caused by temperature stress, especially under low temperature in winter, the asphalt overlay at the seams, cracks, because of excessive tensile stress and cracking formation temperature reflection crack.The mechanism of 3 glass fiber grid to restrain reflection crackThe glass fiber grid has the advantages of high tensile strength, low elongation and no creep

- Q:How do geogrids improve the stability of embankments and slopes?

- Geogrids improve the stability of embankments and slopes by providing reinforcement and enhancing the load-bearing capacity of the soil. They are designed to distribute the applied forces more uniformly, reducing the potential for soil movement and erosion. The geogrids act as a barrier, preventing the sliding of soil particles and promoting interlocking between the soil and the geogrid material. This reinforcement helps to increase the overall stability of the embankments and slopes, reducing the risk of slope failure and collapse.

- Q:What are the advantages of using geogrids in ground improvement for load transfer platforms?

- Geogrids offer several advantages in ground improvement for load transfer platforms. Firstly, they provide enhanced stability by distributing load forces across a wider area, reducing the risk of settlement or failure. Secondly, geogrids increase the bearing capacity of the soil, allowing for the construction of heavier structures or equipment. Additionally, these grids improve soil confinement, preventing the lateral movement of soil particles and reducing the potential for erosion. Moreover, geogrids are easy to install and can be cost-effective compared to alternative methods, making them a preferred choice for ground improvement projects.

- Q:What are the different types of geogrids?

- There are several types of geogrids, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids are designed to provide strength in one direction, typically used for reinforcement applications. Biaxial geogrids offer strength in both directions, making them suitable for applications such as soil stabilization and slope reinforcement. Triaxial geogrids have additional strength in the third dimension, making them ideal for applications involving heavy loads or high tensile forces.

- Q:Can geogrids be used in bridge abutment construction?

- Yes, geogrids can be used in bridge abutment construction. Geogrids are commonly used to reinforce soil and provide stability in various civil engineering applications, including bridge abutments. They help distribute loads and improve the overall performance and longevity of the structure.

- Q:How many Chinese geogrid manufacturers? How many famous

- In foreign markets, the high level of the grid, it is basically the competition with TANSER

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Geogrid for Road Construction with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords