Graphite Electrode With Nipple RP, HP, UHP Good Electrical Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Graphite Electrodes:

We have a complete set of graphite electrode production lines. Our products have excellent structure, good electrical conductivity and thermal conductivity, high resistance to high temperature oxidation and corrosion characteristics. Common power graphite electrode for metallurgical refining, such as electric arc furnace steelmaking plant and other applications. As China's most professional manufacturer of graphite electrode, through the ISO9001:2000 international quality system certification. We are glad to be able to quote you the most competitive price according to your request.

2.Main features of Graphite Electrodes:

1).High electrical conductivity

2).High thermal shock resistance

3).High strength

3. Graphite Electrodes Images:

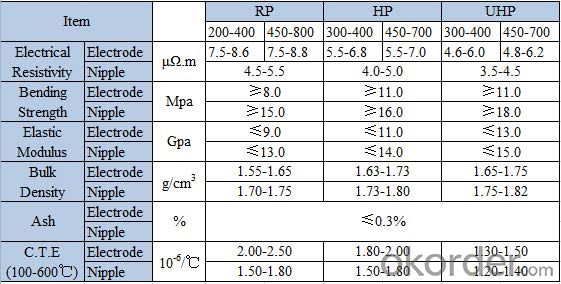

4. Graphite Electrodes Technical Parameters:

Diameter: As requirement

Grades: including RP, HP, UHP.

Nipples: 3 TPI or 4 TPI.

Application: Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

Graphite Electrodes&Company

①How about your company?

A world class manufacturer & supplier of Graphite Electrodes is one of the large scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Classification of graphite electrodes

- Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q:What is anodized graphite?

- Electrochemical graphite is made of graphite, coke and other raw materials, placed in the high temperature of more than 2500 degrees in the furnace, processed into products.

- Q:How long is the graphite electrode machining cycle?

- The dust produced in the processing of graphite electrode is relatively large, the possible intrusion to the machine tool guide screw and spindle, which requires a corresponding machining device of graphite graphite dust machine, sealing better, because the graphite toxic.

- Q:What about graphite electrodes for steel mills?

- Hebei North graphite electrode factory produces various specifications of graphite electrode, with low resistance, high density, small ash, and so on, so that less tons of steel-making, quality is good

- Q:Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- Look at what kind of graphite electrode you need. Now, the resistivity of ordinary power graphite electrode in our factory is 7.5-8.5. It is not clear that the graphite electrode is dipped in 6--7.3. copper

- Q:How to solve the problem of graphite electrode being crushed during electrolysis

- I can only use the experience of the past to tell you that if you want to save money easily, the time can be considered as the costA thick graphite stick; inexpensive

- Q:Graphite electrode press device

- (1) ordinary power graphite electrode, using graphite electrode with current density lower than 17A / cm 2, is mainly used in steel-making, smelting silicon, refining yellow phosphorus and other common power electric stove(2) anti oxidation coating graphite electrode. The surface is coated with an anti oxidation protective layer of graphite electrode to form a protective layer which has both conductive and high-temperature oxidation resistance, thus reducing the electrode consumption during steelmaking

- Q:What's the use of carbon?

- Oxidation resistant coating graphite electrode. A graphite electrode coated with an antioxidant protective layer is applied to form a protective layer that is conductive and resistant to oxidation at high temperature, thereby reducing electrode consumption during steelmaking.

- Q:How to improve the efficiency of graphite electrode milling, please tell me

- The technical development of the high-speed machining center lays the foundation for improving the milling efficiency and quality of the graphite electrode, especially for the milling of the small electrode with complicated shape and thin wall. In the EDM mold processing, the graphite electrode needs to be processed by the high-speed machining center (HSM), so the demand for HSM machine tools is also increasing. But for some time, because of the technological developments in hard steel processing, it seems possible to make graphite electrodes an obsolete technology.

- Q:Classification, uses and manufacturers of graphite electrodes

- The difference between graphite electrodesMainly from the current, density, resistance, bending strength, ash parameters are measured

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Graphite Electrode With Nipple RP, HP, UHP Good Electrical Conductivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords