Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Circular Column Formwork Outrigger For Scaffolding

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

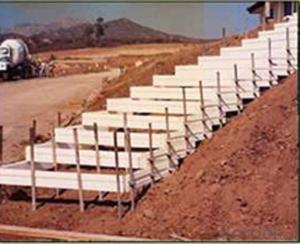

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port.

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

(4) Formwork System Scaffolding & Accessories:

Light Duty Shoring prop and Heavy Duty Shoring Prop; Wing nuts and Tie rods; RASTO clamp and so on.

FAQ Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Full energy with affluent experience team.

- Q:Can steel frame formwork be used for the construction of government buildings?

- Yes, steel frame formwork can be used for the construction of government buildings. Steel frame formwork provides a strong and durable solution that is capable of withstanding the demands of large-scale construction projects. It offers high stability, flexibility, and precision, making it suitable for the construction of government buildings that often require high-quality and long-lasting structures. Additionally, steel frame formwork allows for efficient construction processes, leading to cost-effective and timely completion of government building projects.

- Q:How does steel frame formwork handle the placement of fire protection materials within the concrete structure?

- Steel frame formwork provides a highly efficient and effective solution for the placement of fire protection materials within concrete structures. The steel frame formwork system consists of modular panels and frames that are assembled to create a temporary structure for pouring and shaping the concrete. When it comes to fire protection, steel frame formwork allows for easy and precise installation of fire protection materials such as fireproofing coatings or fire-resistant boards. These materials can be applied directly to the surface of the steel frame formwork panels before the concrete is poured. The steel frame formwork system is designed to withstand the high temperatures that occur during a fire. It acts as a barrier, protecting the underlying concrete structure from the direct heat and flame exposure. Additionally, the steel frame formwork system provides structural integrity to the concrete, ensuring that it remains stable and intact even under fire conditions. Furthermore, steel frame formwork allows for flexibility in the placement of fire protection materials. Different areas of the concrete structure may require varying levels of fire resistance, and the modular nature of steel frame formwork allows for easy customization and adjustment to meet these specific requirements. In summary, steel frame formwork handles the placement of fire protection materials within the concrete structure by providing a stable and secure temporary structure for pouring and shaping the concrete. It allows for precise installation of fire protection materials, offers structural integrity and protection against high temperatures, and allows for flexibility in meeting specific fire resistance requirements.

- Q:How do you ensure the quality of steel frame formwork?

- Ensuring the quality of steel frame formwork is crucial in construction projects to ensure the structural integrity and safety of the buildings. There are several methods and practices that can be implemented to guarantee the quality of steel frame formwork: 1. Source materials from reputable suppliers: It is essential to procure steel frame formwork materials from trusted and certified suppliers who adhere to strict quality control standards. This ensures that the materials used in the formwork meet the required specifications and have undergone rigorous testing. 2. Conduct regular inspections: Regular inspections should be carried out during the manufacturing process to check for any manufacturing defects or inconsistencies. This includes inspecting the welds, joints, and overall construction of the formwork. 3. Perform quality tests: Various quality tests should be conducted on the steel frame formwork to verify its strength, durability, and performance. These tests can include load testing, bending tests, and material composition analysis. By conducting these tests, any potential weaknesses or defects can be identified and corrected before the formwork is used on-site. 4. Follow industry standards and guidelines: It is important to adhere to industry standards and guidelines, such as those set by the International Organization for Standardization (ISO) or local regulatory bodies. These standards provide a framework for quality assurance and ensure the formwork meets the required specifications. 5. Proper storage and handling: Steel frame formwork should be stored in a dry and protected environment to prevent corrosion and damage. Proper handling techniques should be followed to avoid any bending or distortion of the formwork components. 6. Regular maintenance and repair: Steel frame formwork should be regularly inspected and maintained to ensure its structural integrity. Any signs of wear, damage, or rust should be addressed promptly by repairing or replacing the affected components. 7. Training and supervision: Proper training should be provided to the construction workers who are responsible for assembling and using the steel frame formwork. Regular supervision should be conducted to ensure that the formwork is being used correctly and that any potential issues are addressed promptly. By implementing these measures, construction professionals can ensure the quality of steel frame formwork, leading to safer and more reliable construction projects.

- Q:Can steel frame formwork be used for both beam and column construction?

- Indeed, steel frame formwork proves to be suitable for the construction of both beams and columns. This versatile and resilient system is widely utilized in construction endeavors to provide concrete structures with support and structure. Comprised of steel frames, panels, and accessories, this system can be effortlessly assembled and disassembled, rendering it appropriate for a multitude of construction elements, such as beams and columns. When it comes to beam construction, steel frame formwork can be tailored to meet the specific dimensions and shape requirements of the beam. The formwork system is designed to endure the pressure exerted by the weight of the concrete, and it can be easily modified to accommodate various beam sizes and configurations. The steel frames offer stability and strength, ensuring the formwork remains intact throughout the concrete pouring and curing process. Similarly, steel frame formwork can be employed for column construction as well. The formwork system can be adjusted to mold the desired shape and size of the column. The steel frames and panels can be seamlessly connected and aligned, creating a steadfast and secure formwork structure. This formwork design is engineered to withstand the pressure applied by the wet concrete, guaranteeing that the column retains its shape and strength during the concrete curing process. In conclusion, steel frame formwork is an adaptable system that can be utilized for both beam and column construction. Its flexibility, durability, and user-friendly nature make it a favored choice for construction projects of varying scales and complexities.

- Q:What are the transportation and logistics considerations for steel frame formwork?

- When it comes to steel frame formwork, there are several transportation and logistics considerations that need to be taken into account. Firstly, the weight and size of the steel frames must be considered. Steel is a heavy material, so the transportation method must be able to handle the weight. It is important to ensure that the vehicle used for transportation, such as trucks or trailers, is capable of carrying the weight of the steel frames and that the frames can be securely loaded and unloaded. Another consideration is the protection of the steel frames during transportation. Steel is susceptible to corrosion and damage, so proper packaging and covering should be used to protect the frames from exposure to the elements. This could include using plastic or waterproof covers, as well as ensuring that the frames are well-secured during transportation to prevent any shifting or movement that could cause damage. The logistics of delivering steel frame formwork to the construction site also need to be considered. Factors such as the distance between the manufacturing facility and the construction site, as well as the route and transportation infrastructure, should be taken into account. It is important to plan the logistics to ensure timely delivery and minimize any disruptions to the construction schedule. In addition, it is crucial to have a well-organized inventory management system for steel frame formwork. This includes tracking the quantity, condition, and location of the formwork frames to ensure they are readily available when needed and to avoid any delays or inefficiencies in the construction process. Overall, transportation and logistics considerations for steel frame formwork involve addressing the weight and size of the frames, protecting them during transportation, planning the logistics of delivery, and implementing an effective inventory management system. By carefully considering these factors, construction projects can ensure the smooth and efficient transportation and use of steel frame formwork.

- Q:Is steel frame formwork resistant to fire?

- Steel frame formwork is indeed fire resistant. Not only is steel a non-combustible material, but it also does not aid in the propagation or escalation of fires. Its melting point, which usually reaches approximately 1370 degrees Celsius, allows it to endure high temperatures without compromising its structural integrity. Hence, steel frame formwork proves to be a secure and dependable option for construction ventures that prioritize fire resistance. Moreover, steel's resilience and robustness guarantee that the formwork remains undamaged even in the most severe fire circumstances, offering additional safeguarding to the developing structure.

- Q:Does steel frame formwork require any specific vibration techniques for concrete compaction?

- Concrete compaction when using steel frame formwork necessitates the application of specific vibration techniques. Steel frame formwork is a construction system that supports newly poured concrete and guarantees its desired shape. In order to eliminate air voids and promote adequate bonding between the concrete and reinforcement, the concrete within the formwork must be compacted. Vibration serves as a crucial compaction method. By removing trapped air bubbles, vibration prevents concrete weakness and reduces the risk of decreased strength. Additionally, vibration facilitates the even distribution and consistent density of the concrete in all corners and tight spaces of the formwork. For effective compaction with steel frame formwork, it is advisable to employ either internal vibrators or external vibrators. Internal vibrators, also referred to as immersion or poker vibrators, are vertically inserted into the concrete at regular intervals. These vibrators generate high-frequency vibrations that consolidate the concrete. On the other hand, external vibrators are affixed to the formwork itself. They produce vibrations that are transmitted to the concrete via the formwork. External vibrators are commonly used for larger areas or when a uniform vibration is necessary. The specific techniques for concrete compaction with steel frame formwork are contingent upon variables such as the concrete mix design, formwork dimensions, and desired finish. Adhering to the manufacturer's guidelines and employing best practices for vibration techniques is essential. In conclusion, specific vibration techniques are required for concrete compaction when using steel frame formwork. These techniques involve the utilization of internal or external vibrators to ensure proper consolidation and eliminate air voids within the freshly poured concrete. By following recommended practices and guidelines, a durable and high-quality concrete structure can be achieved.

- Q:What are the key considerations for selecting the appropriate steel frame formwork supplier?

- When choosing a steel frame formwork supplier, there are several important factors to take into account. These factors include: 1. Quality and durability: It is crucial to select a supplier that offers high-quality and durable steel frame formwork. The formwork should be able to withstand the pressure and weight of the concrete without any deformations or failures. 2. Customization options: Different construction projects may have specific formwork dimensions and configurations. Therefore, it is essential to choose a supplier that provides customization options to meet the project's specific needs. 3. Efficiency and user-friendliness: The formwork system should be designed for easy assembly and disassembly, allowing for efficient and time-saving construction processes. It should also be user-friendly, with clear instructions and an intuitive design. 4. Availability and delivery time: Ensuring timely availability of the formwork is crucial for the smooth progress of the construction project. Therefore, it is important to select a supplier that has a reliable and efficient delivery system to ensure on-time delivery. 5. Safety features: The formwork system should have sufficient safety features to protect workers during construction. This includes non-slip surfaces, guardrails, and secure connection points. 6. Technical support and after-sales service: A reputable supplier should provide excellent technical support and after-sales service. This includes assistance with installation, troubleshooting, and maintenance of the formwork system. 7. Price and cost-effectiveness: While price should not be the sole determining factor, it is important to consider the overall cost-effectiveness of the formwork system. This includes factors such as longevity, reusability, and the supplier's ability to provide cost-saving solutions. 8. Reputation and track record: It is advisable to choose a supplier with a good reputation and a proven track record in providing high-quality steel frame formwork. Reading customer reviews and seeking recommendations can help assess a supplier's reliability and performance. By considering these key factors, construction professionals can select the most suitable steel frame formwork supplier for their project, ensuring a successful and efficient construction process.

- Q:What are the different types of scaffolding systems used in conjunction with steel frame formwork?

- There are several different types of scaffolding systems that can be used in conjunction with steel frame formwork. These systems are designed to provide a safe and stable platform for workers to access and work on the formwork structure. Some of the most common types of scaffolding systems used in conjunction with steel frame formwork include: 1. Frame Scaffolding: This is the most commonly used type of scaffolding system. It consists of vertical steel tubes connected with horizontal and diagonal braces, forming a frame structure. The frame scaffolding provides a stable platform for workers to access the formwork structure. 2. Tube and Coupler Scaffolding: This system uses steel tubes and couplers to create a modular scaffolding structure. The tubes are connected with couplers, which allow for easy assembly and disassembly of the scaffolding. Tube and coupler scaffolding is highly versatile and can be customized to fit the specific requirements of the formwork structure. 3. Ringlock Scaffolding: This system utilizes a unique rosette connection system, which allows for fast and easy assembly of the scaffolding. Ringlock scaffolding is known for its high load-bearing capacity and stability, making it suitable for supporting heavy formwork structures. 4. Cuplock Scaffolding: Cuplock scaffolding is another popular choice for supporting steel frame formwork. It features a unique locking mechanism that securely holds the scaffolding components together. Cuplock scaffolding is known for its simplicity and versatility, making it a preferred choice for many construction projects. 5. Kwikstage Scaffolding: This system is designed to provide a quick and easy assembly of scaffolding. Kwikstage scaffolding utilizes a wedge connection system, allowing for fast and secure installation. It is a versatile system that can be easily adapted to different formwork structures. These are just a few of the many different types of scaffolding systems that can be used in conjunction with steel frame formwork. The choice of scaffolding system will depend on factors such as the specific requirements of the formwork structure, the load-bearing capacity needed, and the ease of assembly and disassembly. It is important to select the appropriate scaffolding system to ensure the safety and efficiency of the construction project.

- Q:How does steel frame formwork reduce the need for additional support structures?

- Steel frame formwork reduces the need for additional support structures by providing a strong and durable framework that can withstand the weight and pressure of the concrete during construction. This eliminates the need for additional columns, beams, or scaffolding, saving time and resources in the construction process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords