FRM 770 series continous bag seaing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1. Description of the sealing machine

FRB-770 series plastic film continuous sealing machine is applicable to small bag seal.

2. Technical parameter

| Item | FRM-770I | FRM-770II | FRM-770III |

| Power supply voltage | AC 220/50 110/60 | ||

| Motor Power (W) | 50 | ||

| Electric Power (W) | 300 * 2 | ||

| Sealing linear speed (m/min) | 0 - 12 ( 0 - 16 ) | ||

| Sealing width (mm) | 12 | ||

| Temperature control range (degree) | 0 - 300 | ||

| Lettering category | Steel wheel indentation printing ( can choose ) | ||

| Seal center to transport station distance (mm) | 10 - 40 | 150 - 270 | 10 - 40 |

| Delivery table size | 840 * 153 | ||

| Delivery platform single maximum weight capacity (kg) | <= 1 | ||

| Delivery platform weight capacity (kg) | <= 3 | ||

| Overall Dimensions ( L*W*H)(mm) | 840*380*320 | 840*380*550 | 840*550*800 |

| Net weight (kg) | 32 | 47 | 40 |

3.Main features

Constant temperature controllable, the temperature is adjustable

Speed stepless adjustable

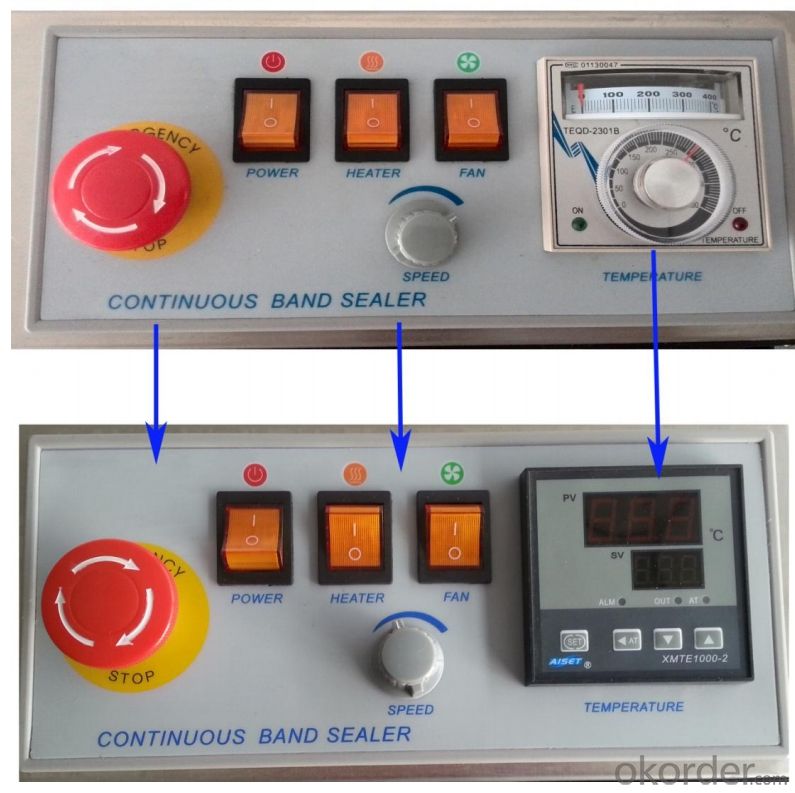

4. Images of the products

Model: FRM-770I

Model: FRM-770II

Model: FRM-770III

Detail image of the parts

Image of the finished sealed samples

5. FAQ

- Payment terms:100% by T/T

- Delivery time: 15 days

- Package: seaworthy plywood carton

- Guarantee period: 12 months

- Q:What are the main plastic forming processes?

- Plastic processing is a complex process, generally divided into the following processing methods:In order to improve the quality of the product and improve the molding efficiency, the pre pressing is used to press the powder or fibrous molding material into a certain shape in advance.Preheating, in order to improve the processing performance and shorten the molding cycle of molding plastics, the molding plastics are heated prior to molding.Molding in the mold to add the required amount of plastic, closed mold and exhaust, at the mold temperature and pressure to maintain a period of time, and then release mold cleaning operations

- Q:What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q:What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q:Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q:The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q:What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

- Q:Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q:The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q:Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q:Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRM 770 series continous bag seaing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords