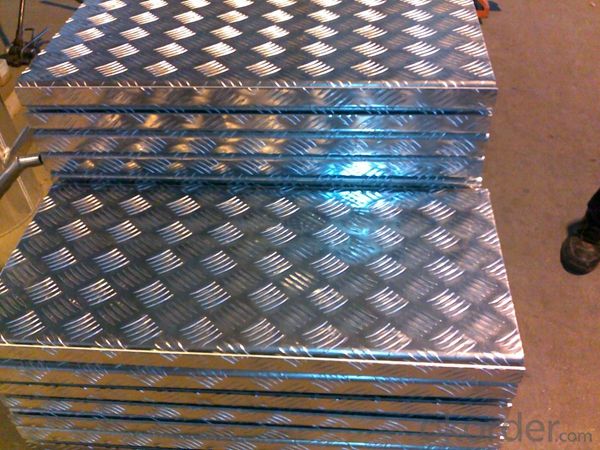

Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can someone please explained what aluminum reacts slowly with dilute acided?Thank you!

- Aluminum metal is not very reactive because of the passivating layer of aluminum oxide, Al2O3, on the surface of the metal. The oxide coating can be dissolved by solutions which are either very acidic or very basic. ======== Follow up ======== Whoa, Nellie. Back the boat up. The oxide coating on aluminum comes from oxygen in the air and covers the surface of the aluminum long before it landed in the acid solution. The dissolved oxygen in the acid solution is NOT the reason for oxygen combining with aluminum. The pH of the solution has little influence on the amount of dissolved oxygen. The partial pressure of O2 above the water and the temperature of the water are much more important to the amount of dissolved oxygen.

- Q:How do aluminum sheets perform in terms of chemical resistance?

- Aluminum sheets generally have good chemical resistance due to the formation of a protective oxide layer on their surface. This oxide layer helps prevent corrosion and protects the aluminum from many common chemicals. However, aluminum can react with certain aggressive acids and alkalis, so it is important to consider the specific chemical environment when assessing its chemical resistance.

- Q:Can aluminum sheets be anodized for improved corrosion resistance?

- Yes, aluminum sheets can be anodized to enhance their corrosion resistance. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and increasing its durability.

- Q:Can the aluminum sheets be painted or coated with a different color?

- Indeed, it is possible to paint or coat aluminum sheets with a different color. Aluminum, being a flexible material, lends itself well to the application of paint or coating in order to achieve the desired color or finish. This can be accomplished using a range of techniques, including powder coating, anodizing, or the use of liquid paint. These methods serve to both protect the aluminum sheet's surface and alter its color or appearance. The selection of the specific paint or coating will hinge upon the particular requirements and desired outcome. On the whole, the practice of painting or coating aluminum sheets is commonplace, granting opportunities for customization and aesthetic enhancement.

- Q:Are aluminum sheets flammable?

- Aluminum sheets, I assure you, are not flammable. Their non-combustible nature is attributed to the fact that aluminum possesses a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit). It neither burns nor supports combustion, rendering it a favored option in numerous sectors, particularly within the construction industry, where fire resistance is paramount.

- Q:Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Aluminum sheets are indeed a fitting choice for HVAC systems. The popularity of aluminum in HVAC systems stems from its numerous advantageous properties. To begin, aluminum is both lightweight and robust, making it effortless to handle and install in HVAC systems. Its low density also enables cost-effective transportation and reduces the overall weight of the HVAC units. Furthermore, aluminum possesses exceptional resistance to corrosion. Given that HVAC systems often encounter moisture and condensation, particularly in air conditioning units, aluminum's corrosion resistance ensures its durability and longevity in such environments. Moreover, aluminum sheets exhibit commendable thermal conductivity, facilitating efficient heat transfer throughout the HVAC system. This property holds particular significance in heating and cooling applications, as it aids in effectively distributing the desired temperature. In addition, aluminum is a non-toxic material, rendering it safe for use in HVAC systems that circulate air within buildings. It does not emit any harmful particles or gases, thereby ensuring the quality of indoor air. Lastly, aluminum is highly recyclable, contributing to its environmental friendliness. The ability to recycle aluminum sheets reduces the carbon footprint associated with HVAC systems and aligns with sustainability objectives. Taking all these advantages into account, aluminum sheets undeniably prove suitable for use in HVAC systems. They offer an optimal combination of strength, corrosion resistance, thermal conductivity, safety, and environmental friendliness.

- Q:Can 101 aluminum sheets be anodized for medical equipment applications?

- Medical equipment applications can involve anodizing 101 aluminum sheets, which creates a protective layer on the surface of the aluminum. This process enhances corrosion resistance, durability, and the overall aesthetic appearance. Anodizing is commonly used in the medical industry to improve equipment performance and longevity, as well as to maintain cleanliness and sterility. The specific alloy, such as 101, does not typically affect the anodizing process, as it can be applied to various grades of aluminum. However, it is crucial to consult with an anodizing specialist or manufacturer to ensure that the specific alloy is suitable for the intended medical equipment application and to determine the most appropriate anodizing process and specifications.

- Q:What keeps things colder- plastic wrap or aluminum foil?

- Aluminum foil. It is thicker, and metal retains heat/cold longer than the thin film of plastic would. I actually use both when I freeze things like lasagna...I use a layer of plastic wrap on it first, then a layer of foil over the top. It creates an extra (albeit fine) layer of insulation.

- Q:Are aluminum sheets suitable for insulation and soundproofing?

- Yes, aluminum sheets can be suitable for insulation and soundproofing purposes. Aluminum is a lightweight, durable, and highly reflective material that can effectively block heat and sound transmission. When used as insulation, aluminum sheets can act as a radiant barrier, reflecting heat away from the insulated space and helping to maintain a comfortable temperature. Furthermore, aluminum sheets can also be used as a soundproofing material to reduce the transmission of noise. The dense structure of aluminum helps to absorb and dampen sound waves, making it an effective solution for minimizing noise pollution. Additionally, aluminum sheets are resistant to corrosion and moisture, making them suitable for both indoor and outdoor applications. Overall, aluminum sheets provide a cost-effective and efficient solution for insulation and soundproofing needs.

- Q:Are aluminum sheets suitable for automotive body panels?

- Yes, aluminum sheets are suitable for automotive body panels for several reasons. Firstly, aluminum is a lightweight material, which helps improve fuel efficiency and overall vehicle performance. This can result in better acceleration, handling, and braking. Additionally, the use of aluminum body panels can contribute to reducing the overall weight of the vehicle, which is particularly important for electric vehicles, as it can extend their range. Secondly, aluminum has excellent corrosion resistance properties. It naturally forms a protective oxide layer on its surface, which helps prevent rusting and deterioration caused by exposure to various weather conditions. This makes aluminum sheets highly durable and long-lasting, ensuring that automotive body panels maintain their structural integrity over time. Furthermore, aluminum is highly malleable and can be easily formed into complex shapes using various manufacturing techniques such as stamping, extrusion, and hydroforming. This allows for greater design flexibility, enabling automakers to create vehicles with sleek and aerodynamic body styles. Additionally, aluminum can be easily joined through welding or adhesive bonding, making it easier to assemble and repair automotive body panels. Moreover, aluminum is a sustainable material as it is highly recyclable. Recycling aluminum requires significantly less energy compared to primary production, resulting in reduced greenhouse gas emissions. This aligns with the growing emphasis on sustainability and environmental consciousness in the automotive industry. Overall, the use of aluminum sheets in automotive body panels offers numerous advantages such as improved fuel efficiency, corrosion resistance, design flexibility, and sustainability. These factors make aluminum a suitable and increasingly popular choice for automakers aiming to enhance the performance, durability, and environmental friendliness of their vehicles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords